Stripping device for armour unit of 10-kV cable

A cable armoring and stripper technology, which is used in cable installation, cable installation devices, equipment for dismantling/armoring cables, etc. Small, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

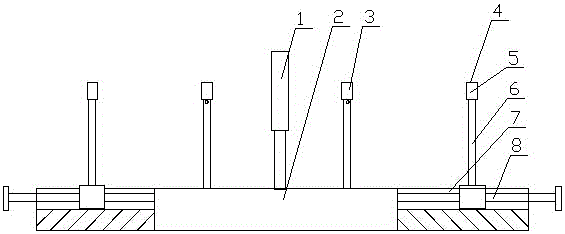

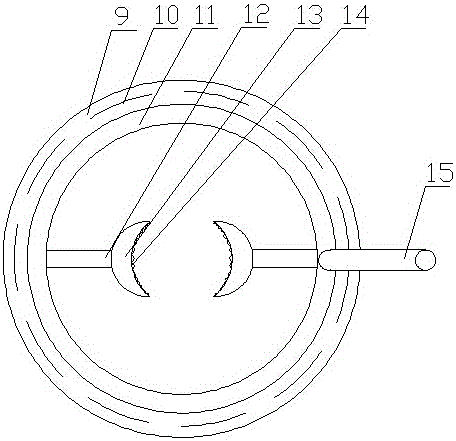

[0031] Such as figure 1 and figure 2 As shown: this embodiment provides a 10kV cable armor stripper, including a base 2, a ring cutting mechanism 1 is arranged in the middle of the base 2, and a center positioning mechanism 3 is arranged on both sides of the ring cutting mechanism 1, so that The two sides of the central positioning mechanism 3 are provided with a tensioning mechanism 4, and the ring cutting mechanism 1 includes an annular bracket 9, and an annular fixing groove 10 is arranged in the annular bracket 9, and an annular slider 11 is arranged in the fixing groove 10, so that A cutting blade 13 is arranged on the annular slider 11 through a telescopic push rod 12, and a rotary drive mechanism is arranged on the annular slider 11.

[0032]The ring cutting mechanism cuts off the armor of the cable. The center positioning mechanism and the stretching mechanism are arranged on both sides of the ring cutting mechanism in sequence. It is to adjust the height of the cab...

Embodiment 2

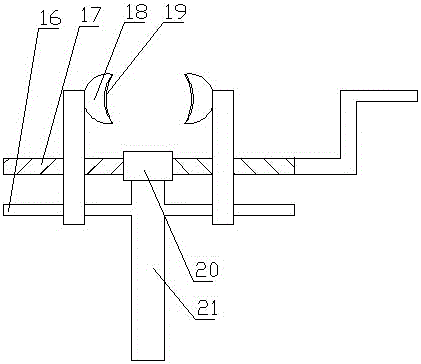

[0037] Such as image 3 As shown: the difference from Embodiment 1 is that the central positioning mechanism 3 includes columns 21 arranged on both sides of the circumcision mechanism 1, a bearing 20 is arranged on the top of the column 21, and a fine-tuning screw 17 is arranged on the bearing 20, The upper part of the column 21 is provided with a horizontal fixed rod 16 , and the two sides of the bearing 20 are provided with arc-shaped clips 18 on the fine-tuning screw 17 and the horizontal fixed rod 16 .

[0038] The two functions of fixing the tensioning cable and adjusting the center of the cable are realized by two mechanisms. The tensioning clamp on the tensioning mechanism is pulled on the two parts of the cable, and adjusted by the tensioning screw on the chute, so that the tensioning bracket moves toward the Move the outside, straighten and fix the cable, regardless of the thickness of the cable. When the cable is fixed and stretched, it is clamped by the arc-shaped ...

Embodiment 3

[0041] Such as figure 1 and figure 2 Shown: its difference with embodiment one is:

[0042] The telescopic mandrel 12 adopts a hydraulic mandrel, and the force of the hydraulic mandrel is more sufficient, and it is easy to control the telescopic distance of the mandrel to ensure the accuracy of cutting.

[0043] The telescopic ejector rod 12 is connected with the controller, and the telescopic ejector rod is connected with the controller. By realizing setting the elongation amount, the controller can control the elongation amount of the telescopic ejector rod during operation, so that the cutting blade only cuts the outer layer Armor cutting, higher precision.

[0044] The controller is a programmable logic controller. Programmable logic controller is a kind of programmable memory, which is used to store programs inside, execute logic operations, sequence control, timing, counting and arithmetic operations and other user-oriented instructions, and through digital or analog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com