Multi-functional electric shredding and slicing device

A slicing device and multi-functional technology, which is applied in metal processing and other directions, can solve the problems of single product function and difficulty in meeting users' various processing requirements for food materials, and achieve the effect of ensuring cutting effect, flatness and parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now with reference to the accompanying drawings, the embodiments of the present invention will be described in detail.

[0022] For the sake of illustration, the width, length and thickness of certain components in the schematic diagrams are sometimes exaggerated.

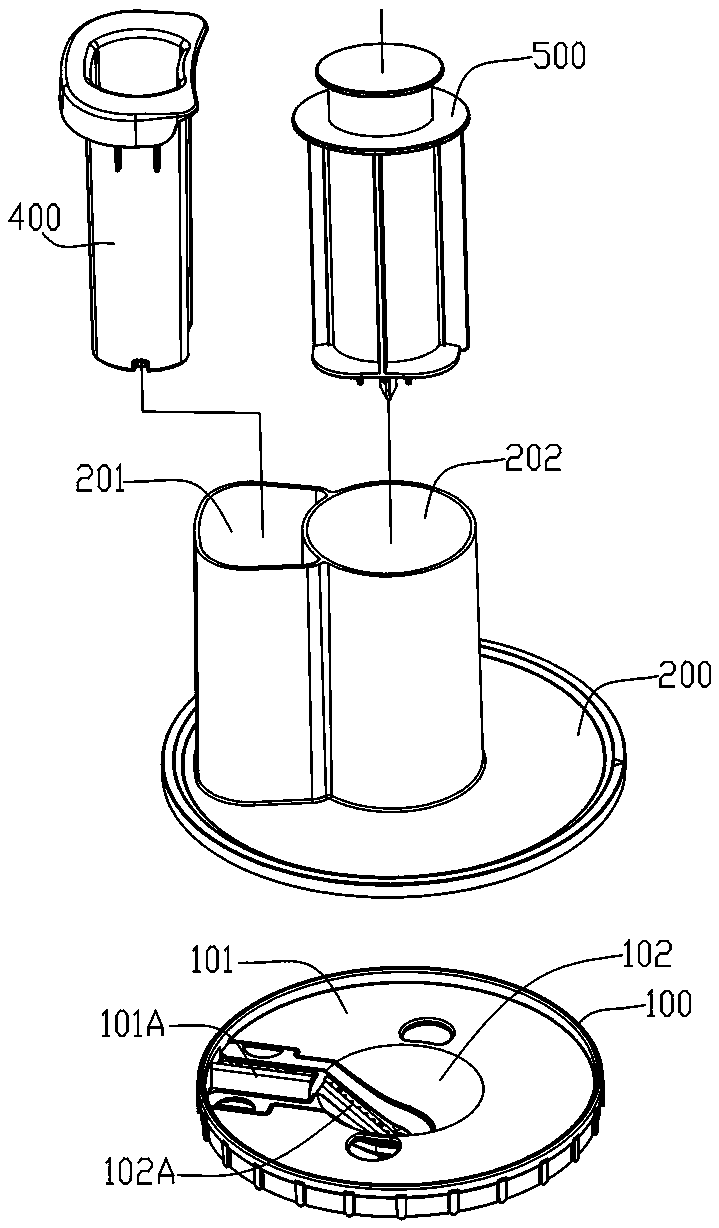

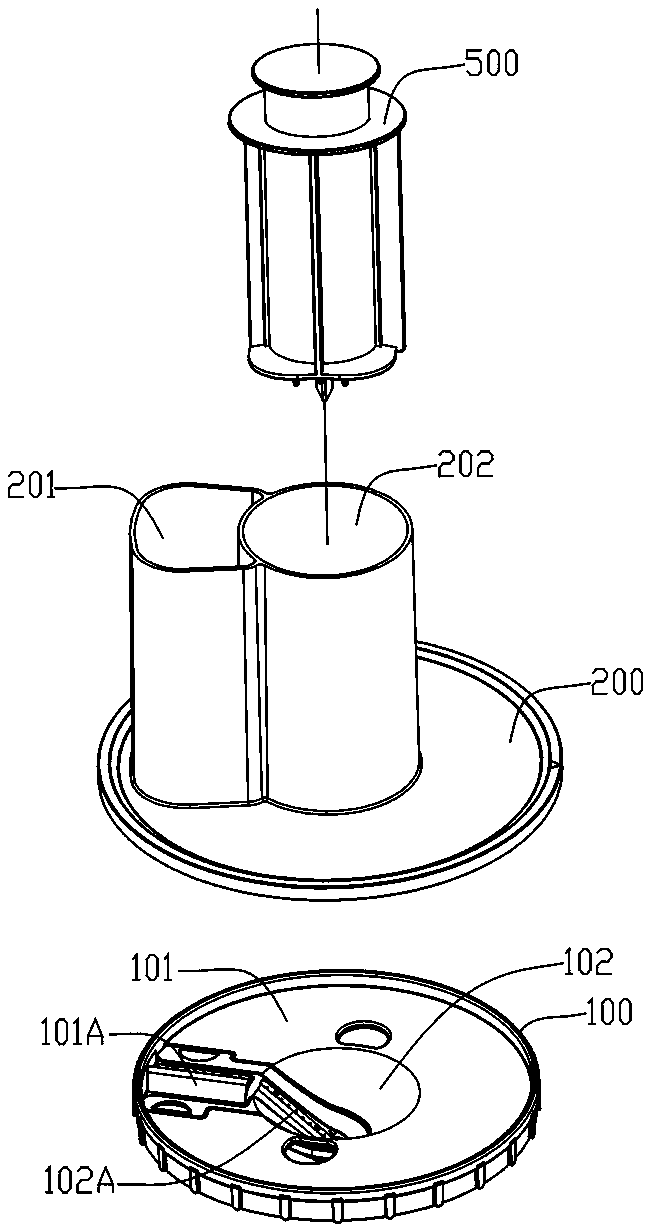

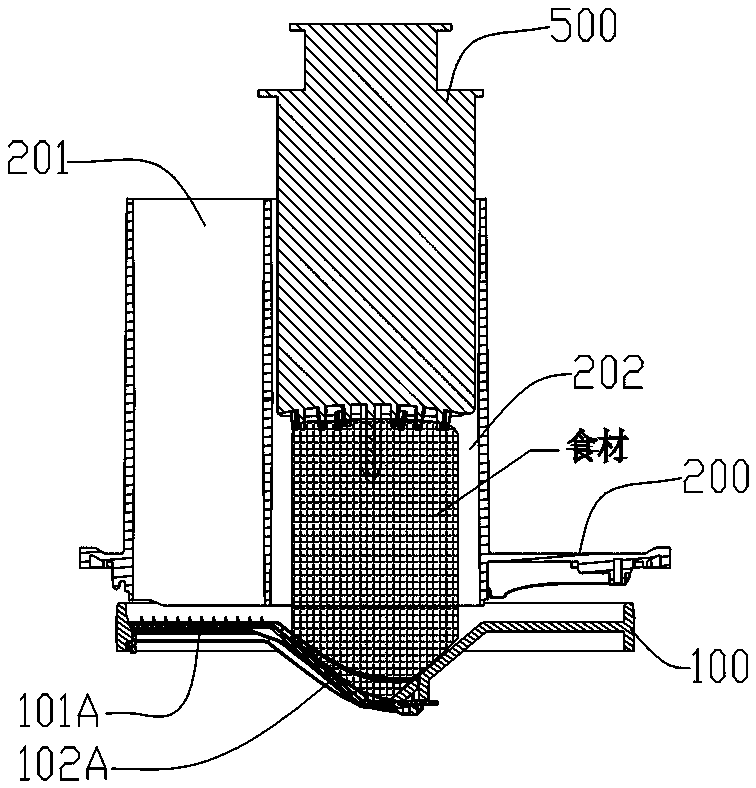

[0023] according to Figure 1 to Figure 8 Shown, the embodiment of a kind of multifunctional electric shredding slicing device comprises:

[0024] The cutting cutterhead 100 is used to realize the cutting function. The cutting cutterhead 100 is driven by the motor and its transmission system installed on the product, rotates around its center, and drives the cutting tool arranged on it to rotate concentrically with it. A processing upper cover 200 for covering the cutting cutter head 100 is provided with a central feeding cylinder 202 and an eccentric feeding cylinder 201 . At the same time, a central push rod 500 is provided in the central feeding cylinder 202 for pushing food materials to perform central...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com