Atomizing core component, atomizer and electronic cigarette

A technology of atomizing core and atomizer, which is applied in the field of electronic cigarettes, can solve problems such as complex transformation, liquid leakage, and exhaustion of smoke liquid, and achieve the effect of simple transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

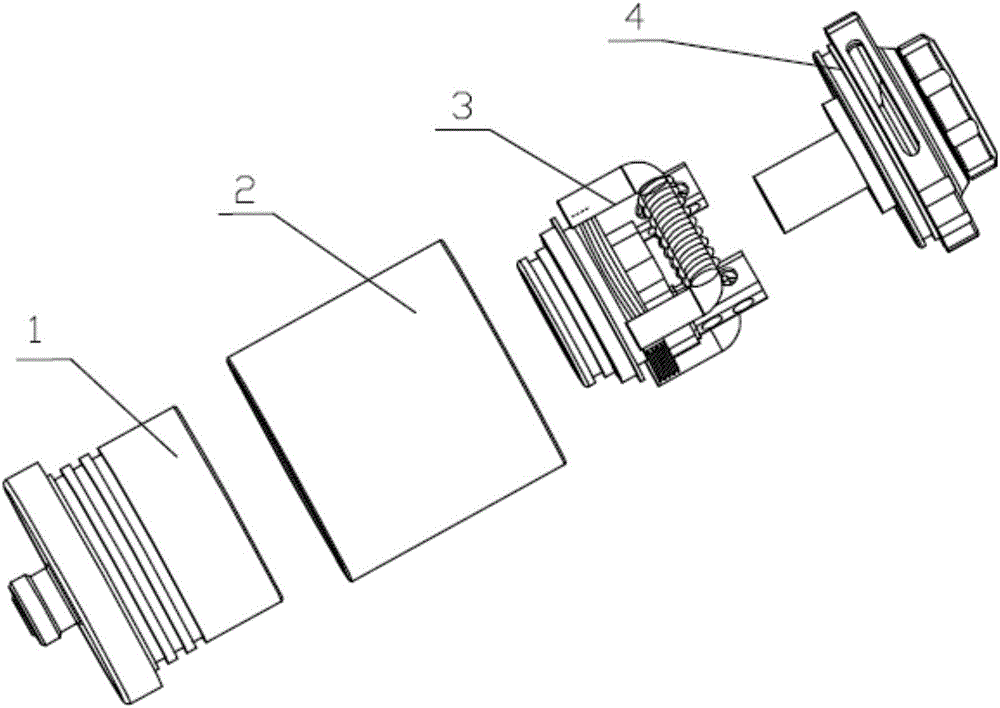

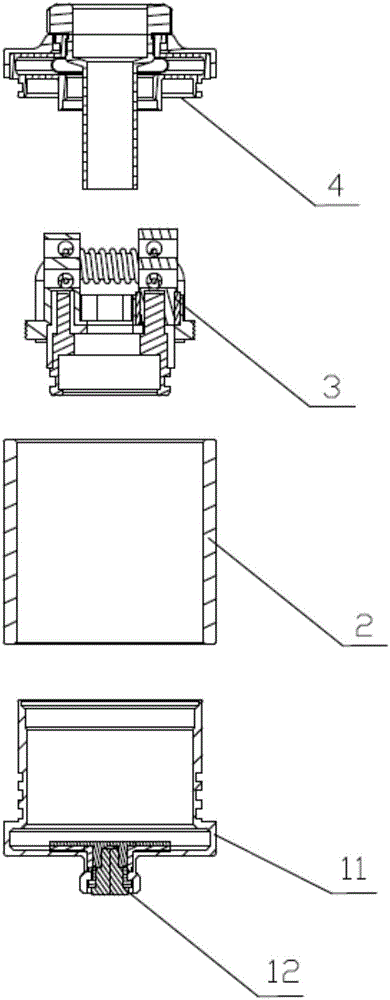

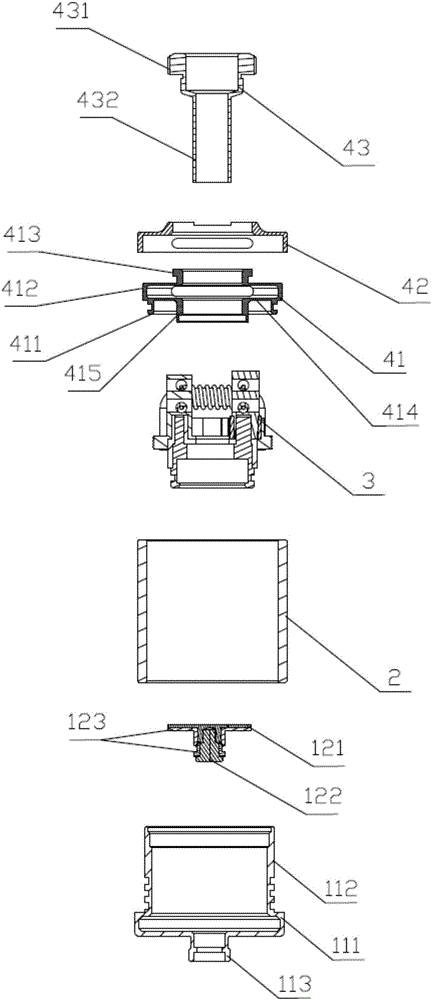

[0036] see figure 1 , the present invention provides an RBA atomizer for electronic cigarettes, including a base 1 , a sleeve 2 , an atomizing core assembly 3 and an upper cover assembly 4 . The base 1 is used for external conduction of the atomizing core assembly 3, the pipe sleeve 2 is set on the base 1, the atomizing core assembly 3 is installed in the pipe sleeve 2 to cooperate with the base 1, and the upper cover assembly 4 is packaged on the top of the pipe sleeve 2 and Cooperating with the atomizing core assembly 3, when it is necessary to inject e-liquid, you only need to remove the upper cover assembly 4 to inject liquid into the atomizing core assembl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap