Batch egg opening device

A batch and cutter head technology, applied in the field of kitchen utensils, can solve the problems of waste, contamination of ingredients, difficulty in cooking for novice cooks, etc., and achieve the effect of easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

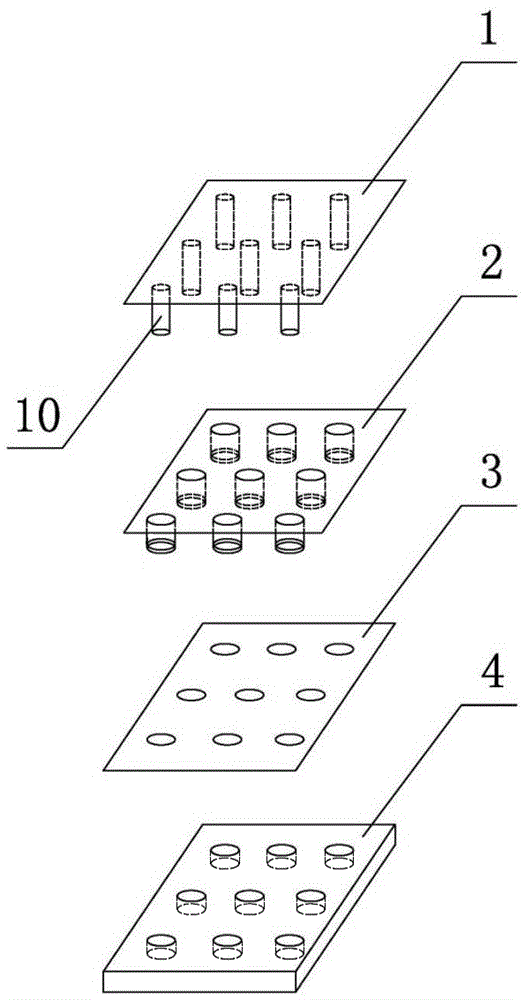

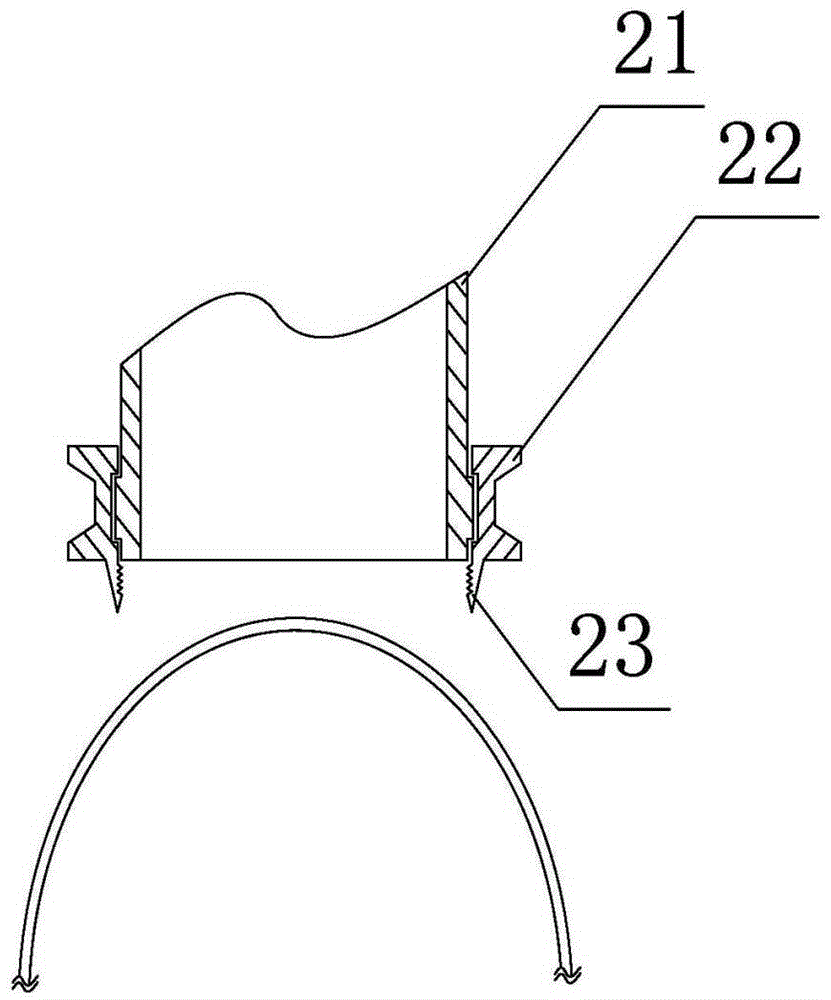

[0008] Below in conjunction with accompanying drawing, the present invention is described in detail: figure 1 In the shown structure, a batch egg opening device with 9 cutting heads arranged in a matrix of 3 rows and 3 columns, including a cleaning layer 1, a cutting head layer 2, a tray 4 and a pressing sheet 3 on the tray layer. The cleaning layer 1 is composed of a cleaning layer bottom plate and a cleaning shaft 10 fixed on the lower end of the cleaning layer bottom plate. The cleaning shaft 10 is a columnar structure for cleaning eggshells stuck in the cutter head layer 2; the cutter head layer 2 includes the cutter head layer bottom plate , cutter head seat 21, cutter head 22 and knife edge 23, the cutter head seat 21 is fixed on the lower end of the cutter head layer base plate, is a hollow columnar structure, and the hollow part is connected with the cutter head layer base plate, allowing the cleaning shaft 10 to pass freely, and the cutter head The lower end of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com