A low-temperature denitration catalyst based on carbonized MOFs and its preparation method

A low-temperature denitrification and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve denitrification catalyst poisoning deactivation, active site reduction, loss of Catalytic activity and other issues, to achieve the effect of easy operation, increased specific surface area, and multiple active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

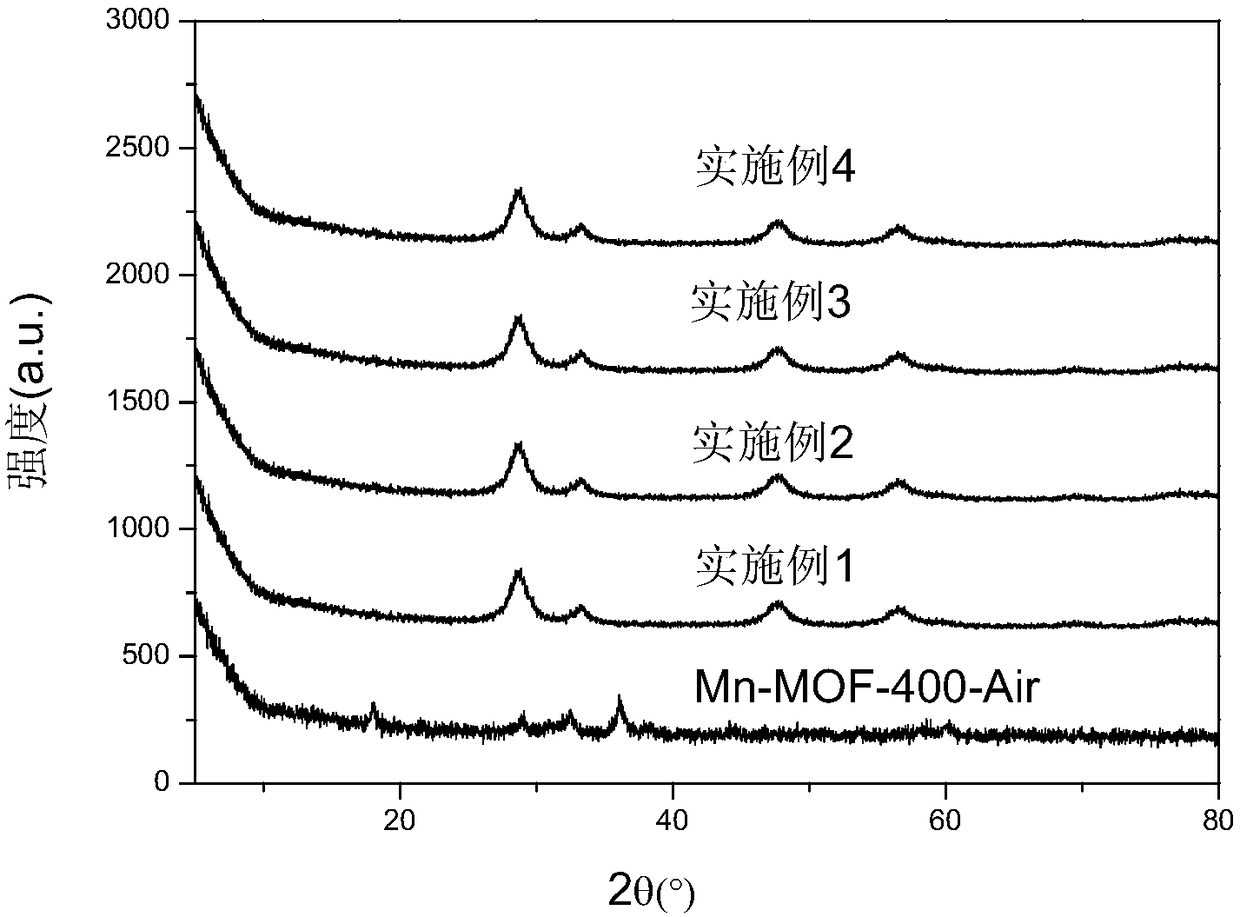

Embodiment 1

[0049] 520 μL of 50% Mn(NO 3 ) 2 solution and 1.94gCe(NO 3 ) 3 ·6H 2 O was added to DMF, 0.8mL of formic acid was added, and the solution was oscillated for 30min by ultrasonic wave until the solution was evenly mixed; then, the solvothermal synthesis reaction was carried out at 80°C for 24h to obtain the Mn-Ce bimetallic organic framework crystal material; the crystal material was washed with DMF and diethyl ether Finally, centrifugal filtration at 5000r / min was used for 5 minutes, and the product was dried in an oven at 100°C; the dried sample was carbonized in a muffle furnace with programmable temperature rise, and the temperature rise process was as follows: (1) Heating stage: first Raise the temperature from room temperature to 400°C with a heating rate of 1°C / min; (2) constant temperature stage: then keep at 400°C for 2 hours; (3) cooling stage: finally let the muffle furnace temperature drop from 400°C to 35.0°C , the cooling rate was 10°C / min, and a low-temperatur...

Embodiment 2

[0051] 520 μL of 50% Mn(NO 3 ) 2 solution and 3.88gCe(NO 3 ) 3 ·6H 2 O was added to DMF, 0.9mL formic acid was added, ultrasonically oscillated for 30min until the solution was mixed uniformly; then solvothermal synthesis reaction was carried out at 90°C for 20h to obtain the Mn-Ce bimetallic organic framework crystal material; the crystal material was subjected to DMF and diethyl ether in sequence Washing, using 5500r / min centrifugal filtration for 7min, put the product into a 100°C oven for drying; put the dried sample into a programmable temperature-raising muffle furnace for carbonization, and the temperature-programming process is as follows: (1) Heating stage: first Raise the temperature from room temperature to 400°C with a heating rate of 1°C / min; (2) constant temperature stage: then keep at 400°C for 2 hours; (3) cooling stage: finally let the muffle furnace temperature drop from 400°C to 35.0°C , the cooling rate was 10°C / min, and a low-temperature denitration ca...

Embodiment 3

[0053] 520 μL of 50% Mn(NO 3 ) 2 solution and 5.82gCe(NO 3 ) 3 ·6H 2 O was added to DMF, 1.0 mL of formic acid was added, ultrasonically oscillated for 30 min until the solution was evenly mixed; then solvothermal synthesis was carried out at 100°C for 16 h to obtain a Mn-Ce bimetallic organic framework crystal material; the crystal material was subjected to DMF and diethyl ether in sequence Washing, centrifugal filtration at 6000r / min for 8min, the product was dried in an oven at 100°C; the dried sample was carbonized in a muffle furnace with programmable temperature rise, and the temperature rise process was as follows: (1) Heating stage: first Raise the temperature from room temperature to 400°C with a heating rate of 1°C / min; (2) constant temperature stage: then keep at 400°C for 2 hours; (3) cooling stage: finally let the muffle furnace temperature drop from 400°C to 35.0°C , the cooling rate was 10°C / min, and a low-temperature denitration catalyst based on carbonized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com