Anti-CO2-poisoning solid oxide fuel cell cathode material and preparation method of solid oxide fuel cell cathode material

A fuel cell cathode, solid oxide technology, applied in battery electrodes, chemical instruments and methods, iron compounds, etc., can solve problems such as reducing the electrochemical performance of cathode catalysts, and achieve improved anti-CO2 poisoning performance, good chemical stability, The effect of excellent resistance to CO2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

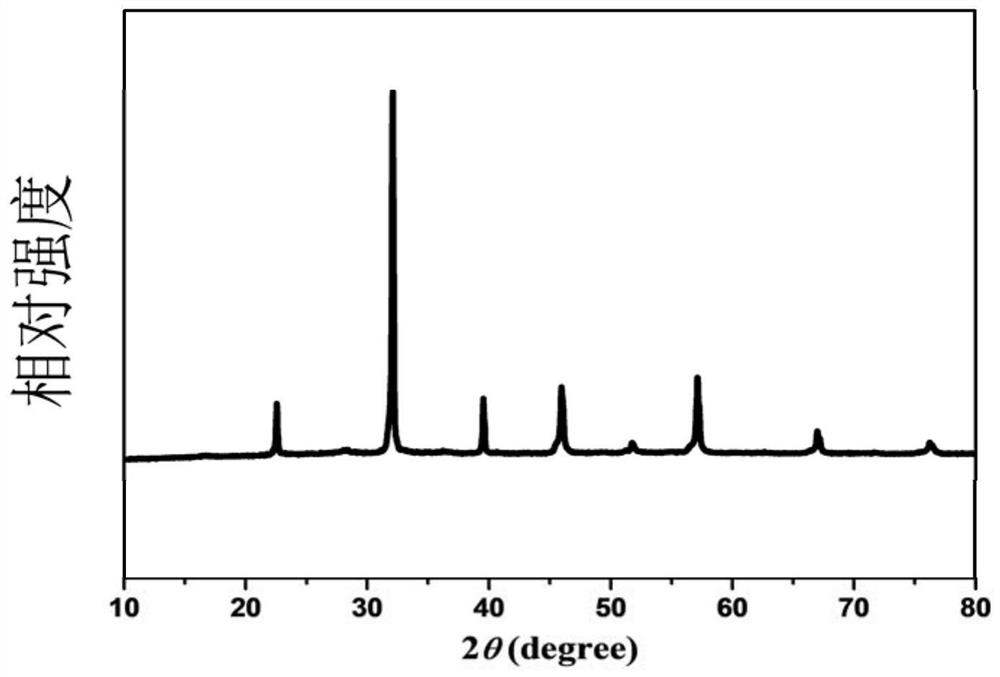

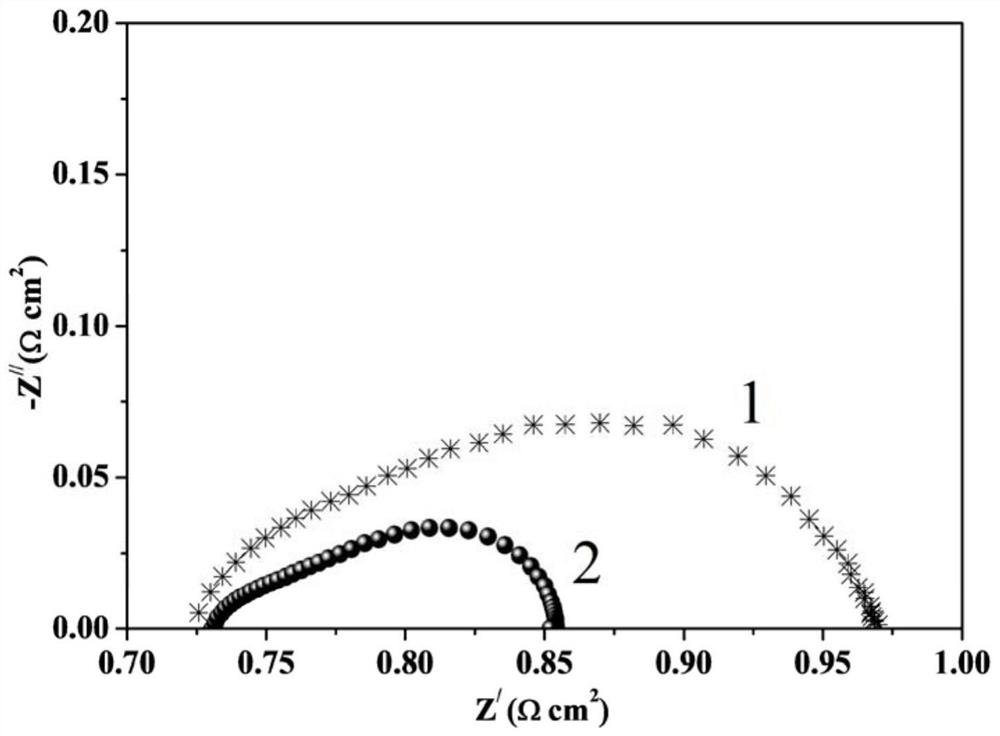

[0025] Specific embodiment 1: In this embodiment, an anti-CO 2 The chemical formula of the poisoned solid oxide fuel cell cathode material is Bi 0.5 Sr 0.5 Fe 1-x m x o 3-δ , wherein M is Ti, Mo, Nb or Ta, the value range of x is 0.1≤x≤0.4, and the value range of δ is 0≤δ≤0.1.

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that: the value range of x is 0.2≤x≤0.3. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Specific embodiment three: This embodiment is an anti-CO 2 The preparation method of the poisoned solid oxide fuel cell cathode material is completed according to the following steps:

[0028] One, Bi 2 o 3 , SrCO 3 , Fe 2 o 3 uniformly mixed with a metal oxide containing element M, then ground, and then calcined to obtain a cathode precursor powder;

[0029] The molar ratio of Bi element, Sr element, Fe element and M element in the cathode precursor powder described in step 1 is 0.5:0.5:(1-x):x, wherein the value range of x is 0.1≤x≤0.4 ;

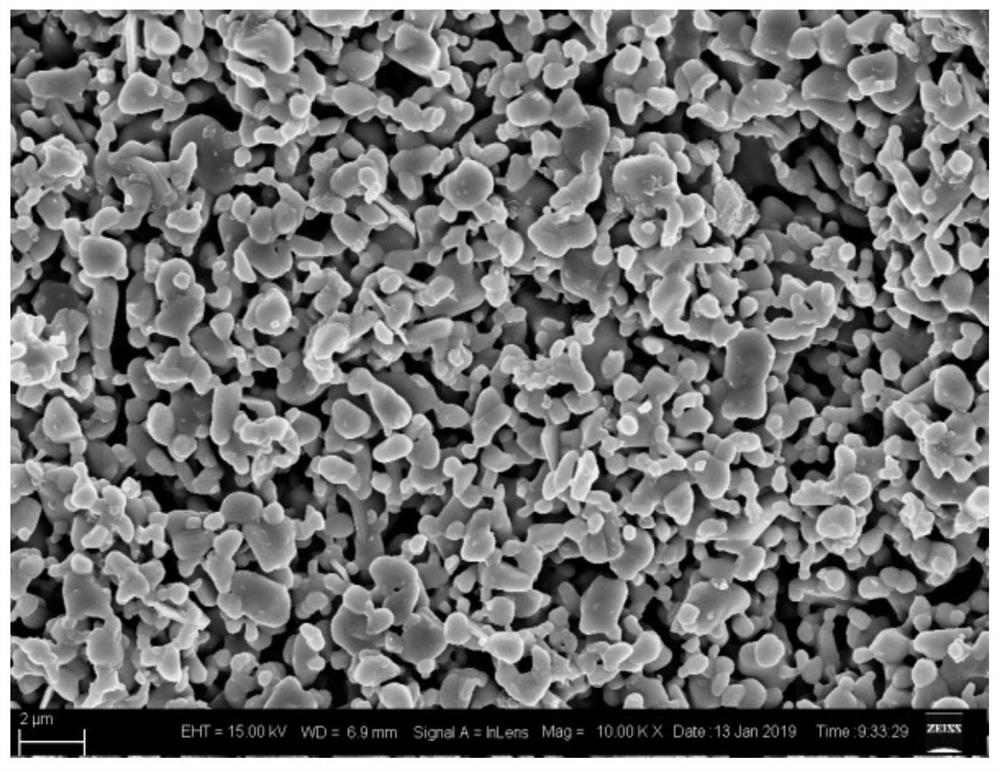

[0030] 2. Put the cathode precursor powder into the mold, and then press the cathode precursor powder under pressure to obtain a cylinder; put the cylinder into a muffle furnace for sintering to obtain a dense ceramic sheet, and then the dense ceramic sheet Grinding to obtain cathode powder;

[0031] 3. The electrolyte powder Ce 0.9 Gd 0.1 o 1.95 Put it into the mold, and then put the electrolyte powder Ce under pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com