A kind of SCR denitration catalyst with high activity and anti-sulfur and preparation method thereof

A denitration catalyst and high-activity technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high catalyst preparation cost, easy blockage and corrosion of air preheater, and high conversion rate. Excellent denitration efficiency, preventing clogging and corrosion, reducing conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

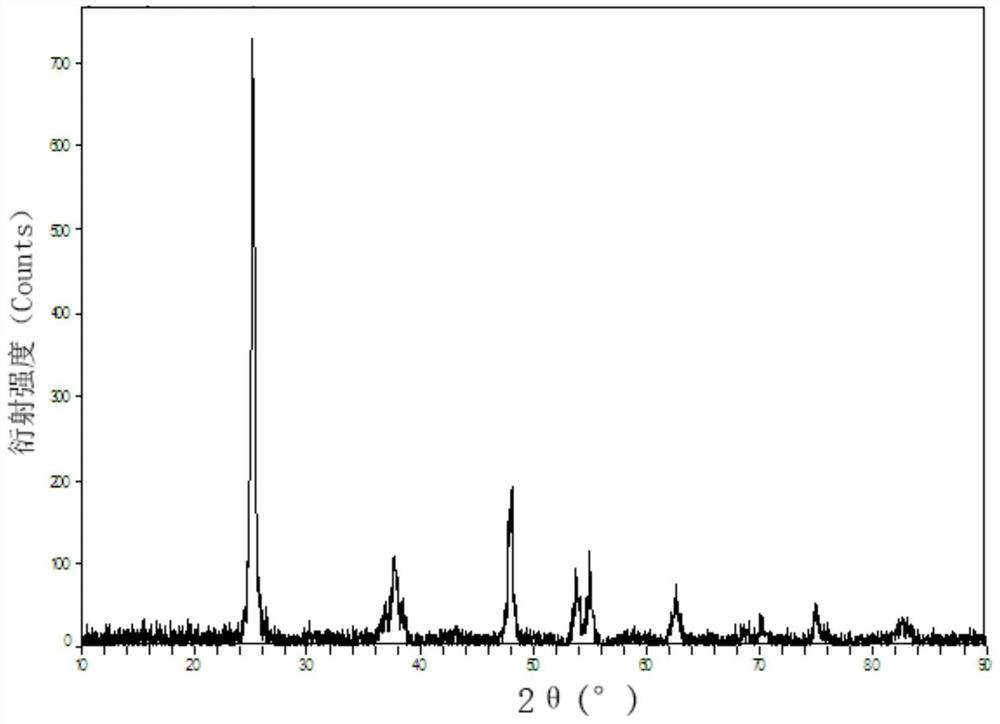

Image

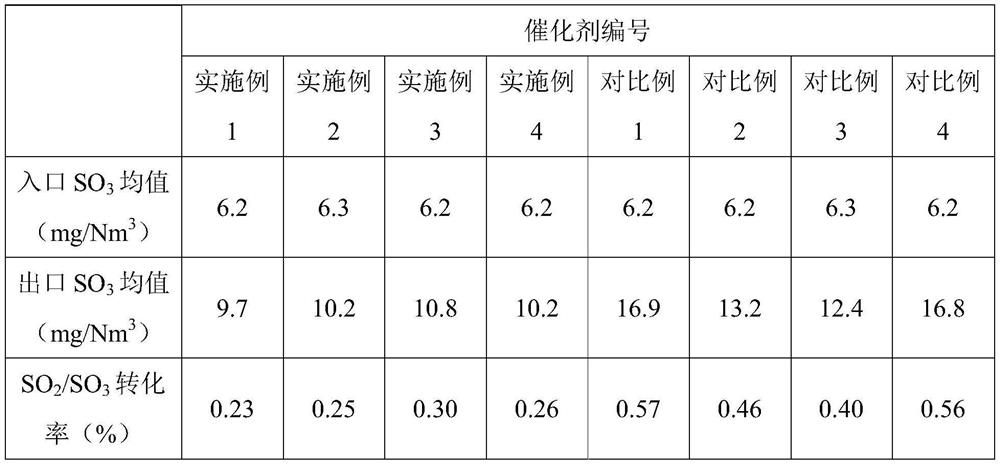

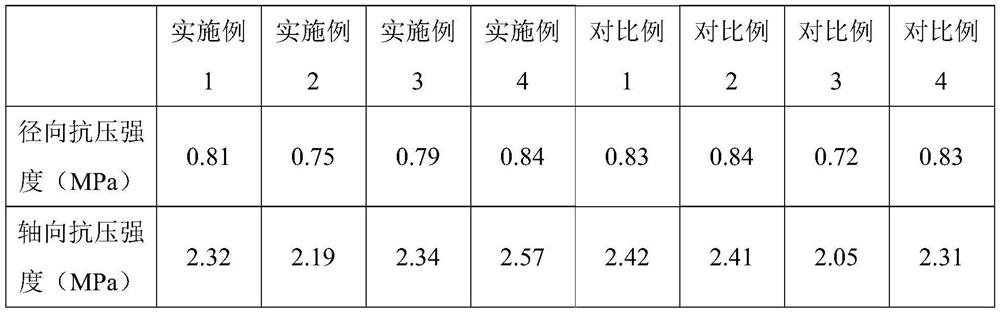

Examples

Embodiment 1

[0052] The present embodiment provides an SCR denitration catalyst, and its preparation method is:

[0053] (1) Preparation of carrier

[0054] (1) Add titanium dioxide, nanoscale carbon black, ammonium bicarbonate, polyethylene oxide, sodium methyl cellulose (CMC) into the mixer, and mix at 1200r / min for 5min to obtain material 1; The mass ratio of white powder, nano-scale carbon black, ammonium bicarbonate, polyethylene oxide and sodium carboxymethyl cellulose is 420:5:1:5:2;

[0055] (2) Add ionized water, ammonia water and lactic acid to material 1 in turn, keep the rotation speed unchanged, stir for 10 minutes, then add glass fiber and continue stirring for 15 minutes to obtain material 2; wherein, the ammonia water is an aqueous solution containing 25%-28% of ammonia, The mass ratio of deionized water, ammonia water, lactic acid, glass fiber and silicic acid is 120:25:30:45:5;

[0056] (3) Kneading the material 2, the rotating speed is 400r / min, the time is 2h, and ext...

Embodiment 2

[0067] The present embodiment provides an SCR denitration catalyst, and its preparation method is:

[0068] (1) Preparation of carrier

[0069] (1) adding titanium dioxide, water-soluble starch, ammonium bicarbonate, polyethylene oxide, sodium carboxymethyl cellulose (CMC) into the mixer, and mixing at 1500r / min rotating speed for 4min to obtain material 1; The mass ratio of white powder, water-soluble starch, ammonium bicarbonate, polyethylene oxide and sodium carboxymethyl cellulose is 420:5:1:5:2;

[0070] (2) Add ionized water, ammonia water and lactic acid to material 1 in turn, keep the rotation speed unchanged, stir for 12 minutes, then add glass fiber and continue stirring for 12 minutes to obtain material 2; wherein, the ammonia water is an aqueous solution containing 25%-28% of ammonia, The mass ratio of deionized water, ammonia water, lactic acid, glass fiber and silicic acid is 120:30:25:40:5;

[0071] (3) Kneading the material 2, the rotating speed is 350r / min, ...

Embodiment 3

[0082] The present embodiment provides an SCR denitration catalyst, and its preparation method is:

[0083] (1) Preparation of carrier

[0084] (1) Add titanium dioxide, nano-carbon fiber, ammonium bicarbonate, polyethylene oxide, sodium carboxymethyl cellulose (CMC) into the mixer, and mix at 1000r / min for 10min to obtain material 1; wherein, titanium dioxide is , the mass ratio of carbon nanofibers, ammonium bicarbonate, polyethylene oxide, and sodium carboxymethyl cellulose is 420:6:1:5:2;

[0085] (2) adding ionized water, ammonia water and lactic acid to material 1 in turn, keeping the rotational speed constant, stirring for 8 minutes, then adding glass fiber and continuing to stir for 10 minutes to obtain material 2; wherein, the ammonia water is an aqueous solution containing 25%-28% of ammonia, The mass ratio of deionized water, ammonia water, lactic acid, glass fiber and silicic acid is 100:20:30:25:3;

[0086] (3) Kneading material 2, the rotating speed is 550r / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com