Low-temperature denitrification catalyst based on carbonized MOFs (metal organic frameworks) and preparation method thereof

A low-temperature denitration and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc. Point reduction and other problems, to achieve the effect of easy operation, increased specific surface area, and favorable diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

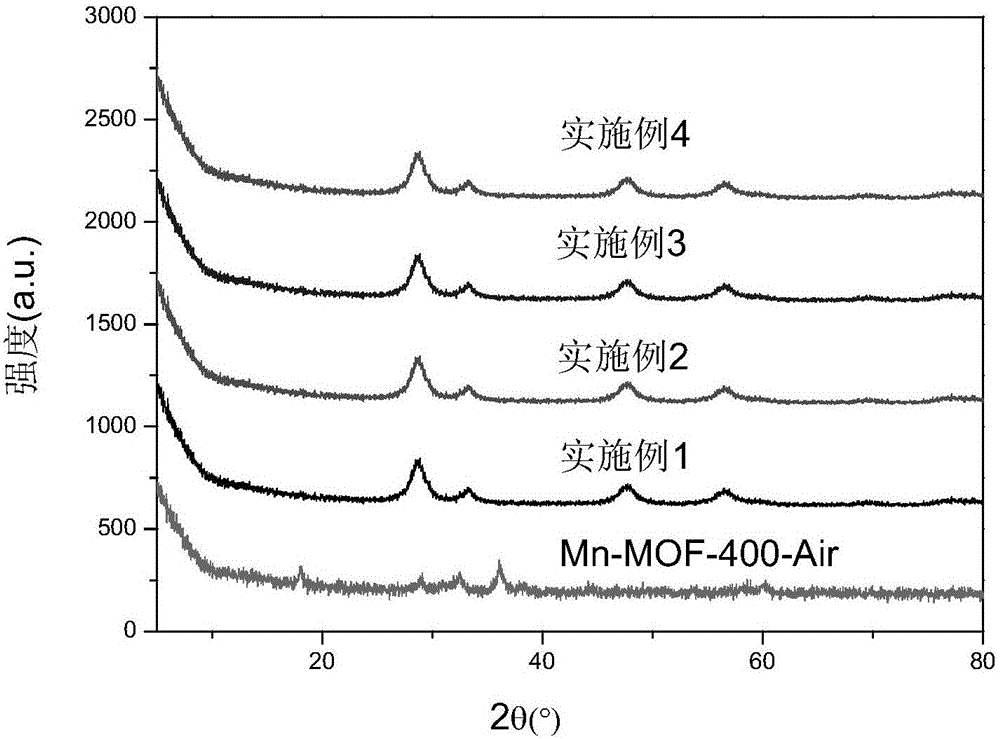

Embodiment 1

[0049] 520 μL of 50% Mn(NO 3 ) 2 solution and 1.94gCe(NO 3 ) 3 ·6H 2 O was added to DMF, 0.8mL of formic acid was added, and the solution was oscillated for 30min by ultrasonic wave until the solution was evenly mixed; then, the solvothermal synthesis reaction was carried out at 80°C for 24h to obtain the Mn-Ce bimetallic organic framework crystal material; the crystal material was washed with DMF and diethyl ether Finally, centrifugal filtration at 5000r / min was used for 5 minutes, and the product was dried in an oven at 100°C; the dried sample was carbonized in a muffle furnace with programmable temperature rise, and the temperature rise process was as follows: (1) Heating stage: first Raise the temperature from room temperature to 400°C with a heating rate of 1°C / min; (2) constant temperature stage: then keep at 400°C for 2 hours; (3) cooling stage: finally let the muffle furnace temperature drop from 400°C to 35.0°C , the cooling rate was 10°C / min, and a low-temperatur...

Embodiment 2

[0051] 520 μL of 50% Mn(NO 3 ) 2 solution and 3.88gCe(NO 3 ) 3 ·6H 2 O was added to DMF, 0.9mL formic acid was added, ultrasonically oscillated for 30min until the solution was mixed uniformly; then solvothermal synthesis reaction was carried out at 90°C for 20h to obtain the Mn-Ce bimetallic organic framework crystal material; the crystal material was subjected to DMF and diethyl ether in sequence Washing, using 5500r / min centrifugal filtration for 7min, put the product into a 100°C oven for drying; put the dried sample into a programmable temperature-raising muffle furnace for carbonization, and the temperature-programming process is as follows: (1) Heating stage: first Raise the temperature from room temperature to 400°C with a heating rate of 1°C / min; (2) constant temperature stage: then keep at 400°C for 2 hours; (3) cooling stage: finally let the muffle furnace temperature drop from 400°C to 35.0°C , the cooling rate was 10°C / min, and a low-temperature denitration ca...

Embodiment 3

[0053] 520 μL of 50% Mn(NO 3 ) 2 solution and 5.82gCe(NO 3 ) 3 ·6H 2 O was added to DMF, 1.0 mL of formic acid was added, ultrasonically oscillated for 30 min until the solution was evenly mixed; then solvothermal synthesis was carried out at 100°C for 16 h to obtain a Mn-Ce bimetallic organic framework crystal material; the crystal material was subjected to DMF and diethyl ether in sequence Washing, centrifugal filtration at 6000r / min for 8min, the product was dried in an oven at 100°C; the dried sample was carbonized in a muffle furnace with programmable temperature rise, and the temperature rise process was as follows: (1) Heating stage: first Raise the temperature from room temperature to 400°C with a heating rate of 1°C / min; (2) constant temperature stage: then keep at 400°C for 2 hours; (3) cooling stage: finally let the muffle furnace temperature drop from 400°C to 35.0°C , the cooling rate was 10°C / min, and a low-temperature denitration catalyst based on carbonized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com