A kind of eutectic catalyst and its solid-state ion exchange method preparation and application

A technology of ion exchange and catalyst, which is applied in the direction of catalyst activation/preparation, molecular sieve catalyst, physical/chemical process catalyst, etc., which can solve the problems of inaccurate control of load capacity, poor hydration performance, poisoning performance, and low catalyst activity, etc., to improve Low temperature hydration resistance, emission reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

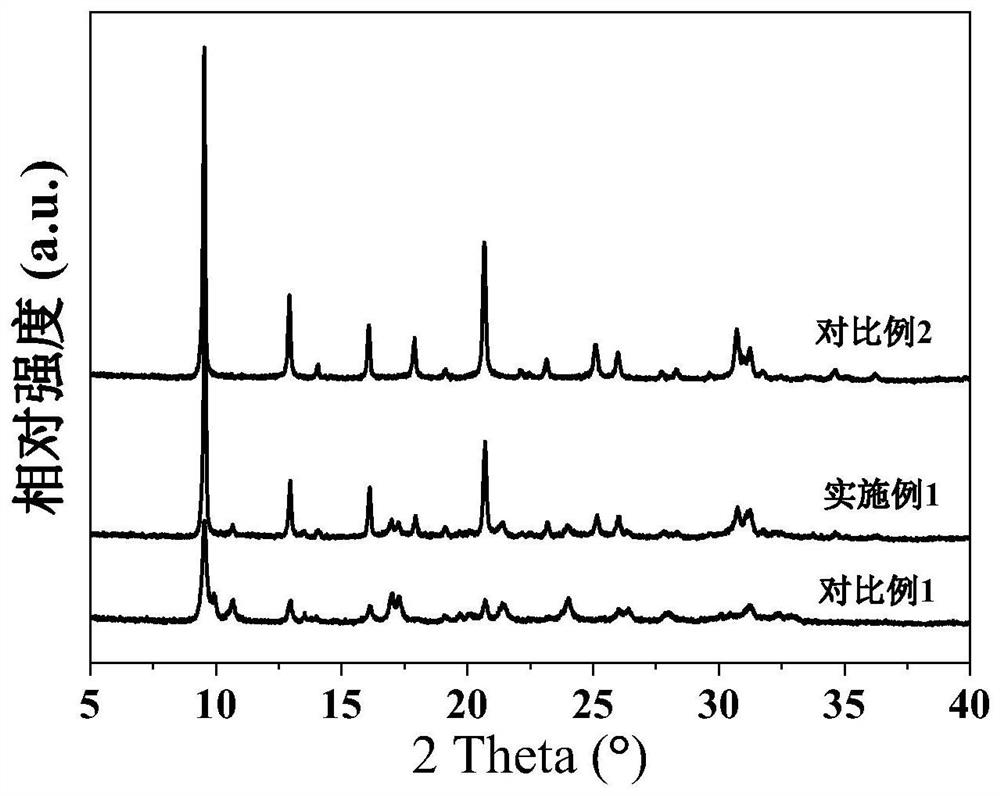

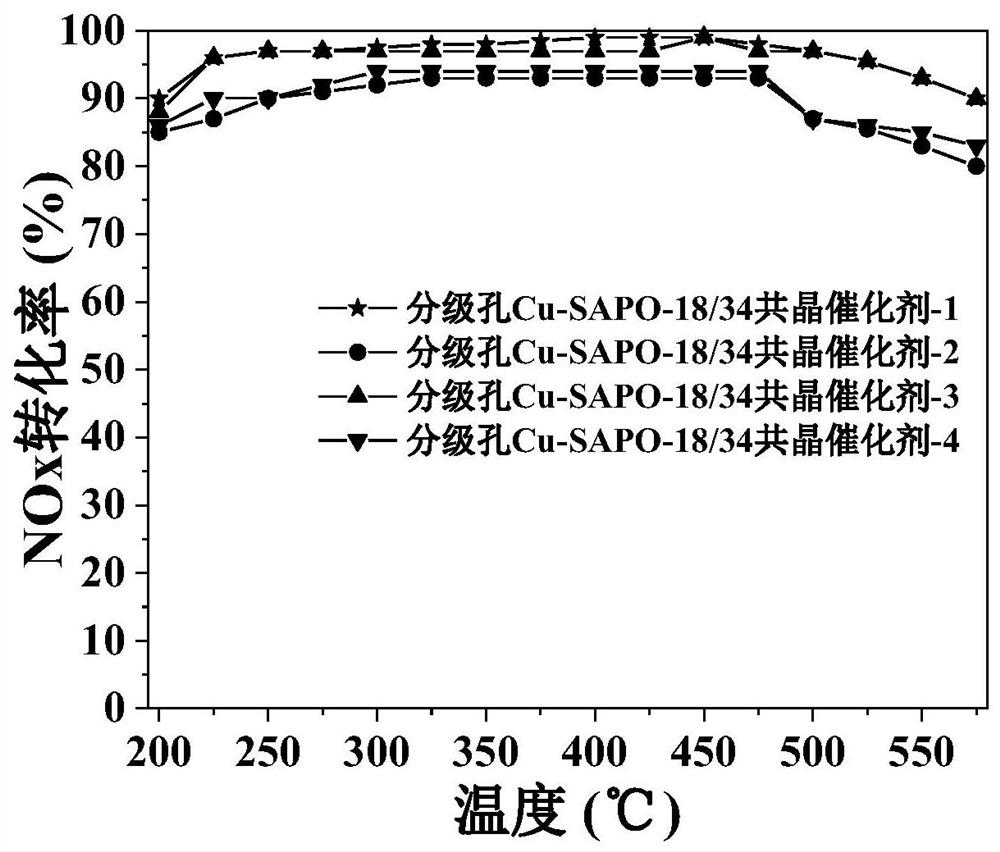

[0032] A kind of solid-state ion exchange preparation method of eutectic catalyst in the present invention, comprises the following steps:

[0033] (1) Dissolving phosphoric acid in deionized water, adding pseudo-boehmite and silica sol and stirring evenly at room temperature;

[0034] (2) Add template agent, pore forming agent and seed crystal subsequently, stir to obtain uniform mixture A;

[0035] (3) Thoroughly transfer the above mixture A to a polytetrafluoroethylene-lined reaction kettle and heat it at 180°C for 4 days to obtain a hydrothermal product. The product is centrifuged, dried, roasted, and ground to obtain a graded pore H-SAPO-18 / 34, then via NH 4 Cl exchange in aqueous solution yields hierarchically pore NH 4 -SAPO-18 / 34;

[0036] (4) Combining Cu-containing precursors with hierarchically porous NH 4 -SAPO-18 / 34 was stirred in a certain amount of deionized water for 1 min to obtain suspension B, and immediately transferred suspension B to a rotary evapora...

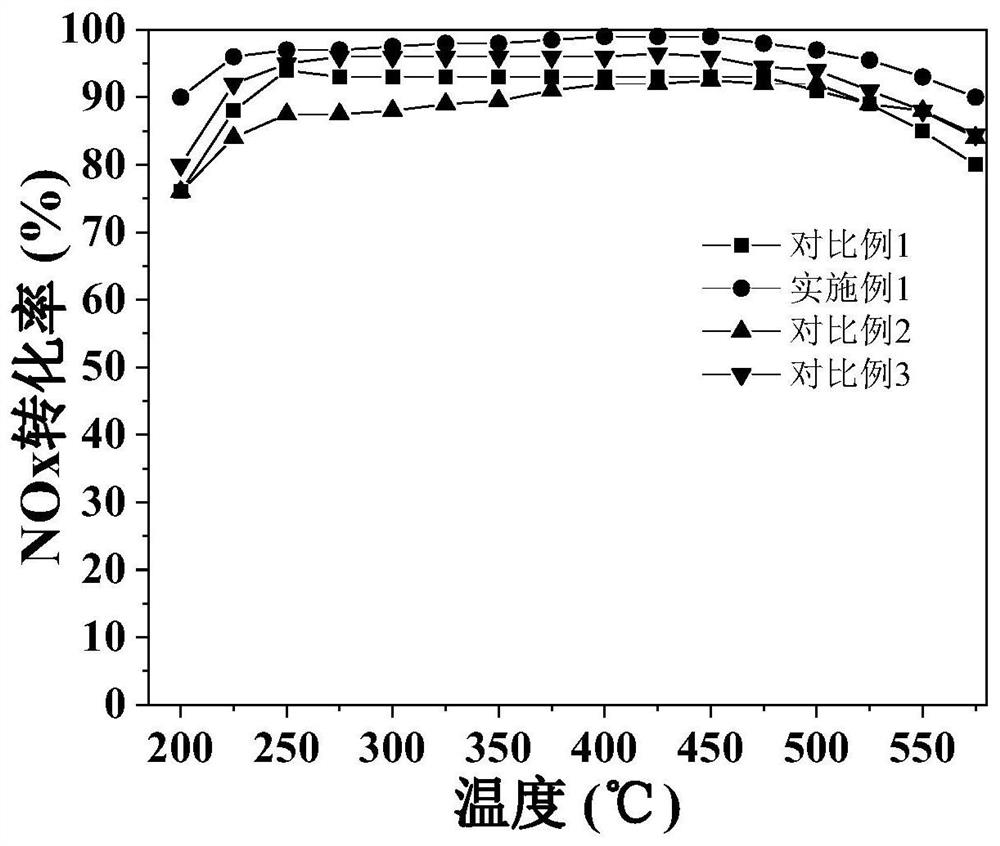

Embodiment 1

[0039] The Cu precursor used in this embodiment is copper nitrate trihydrate (Cu(NO 3 ) 2 3H 2 O), using mixture A ratio of 0.6SiO 2 :1.0Al 2 o 3 :0.9P 2 o 5 :2TEA:45H 2 O, F127 is the NH produced by the pore-forming agent 4 -SAPO-18 / 34 was used as the carrier, and the calcination condition was 600°C for 5h in air atmosphere.

[0040] The specific process is as follows: add 6.23g of phosphoric acid into 23.3g of deionized water and stir for 5min, then add 4.25g of pseudoboehmite and stir for 2h, add 3.6g of silica sol and stir for 1h; then add 6.07g of triethylamine (TEA), 0.5 g F127 and 0.1g SAPO-18 seed crystals were stirred for 3 hours to obtain a homogeneous mixture A; the above mixture A was thoroughly transferred to a polytetrafluoroethylene-lined reactor and hydrothermally heated at 180°C for 4 days to obtain a hydrothermal product, which was centrifuged , dried in water at 110°C for 12h, and roasted at 600°C in air atmosphere for 5h to obtain H-SAPO-18 / 34. We...

Embodiment 2

[0043] The Cu precursor used in this example is copper oxide (CuO), and the proportion of mixture A used is 0.6SiO 2 :1.0Al 2 o 3 :0.9P 2 o 5 :2TEA:45H 2 O, F127 is the NH produced by the pore-forming agent 4 -SAPO-18 / 34 was used as the carrier, and the calcination condition was 750°C for 8h in air atmosphere.

[0044] The specific process is as follows: add 6.23g of phosphoric acid into 23.3g of deionized water and stir for 5min, then add 4.25g of pseudoboehmite and stir for 2h, add 3.6g of silica sol and stir for 1h; then add 6.07g of triethylamine (TEA), 0.5 g F127 and 0.1g SAPO-18 seed crystals were stirred for 3 hours to obtain a homogeneous mixture A; the above mixture A was thoroughly transferred to a polytetrafluoroethylene-lined reactor and hydrothermally heated at 180°C for 4 days to obtain a hydrothermal product, which was centrifuged , dried at 110°C for 12h, and roasted at 750°C for 8h under air atmosphere to obtain H-SAPO-18 / 34. Weigh 10g of H-SAPO-18 / 34 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com