Sorting device for plate production line

A sheet metal production line and sorting device technology, applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve the problems of uniform and inconsistent thickness of shavings, achieve improved sorting effect, improve Practicality, the effect of optimizing the distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

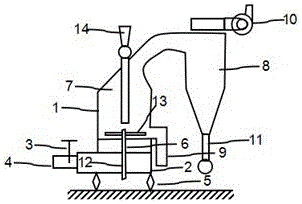

[0017] This embodiment: as figure 1 As shown, a sorting device for a sheet material production line includes a sorting bucket 1, the bottom end of the sorting bucket 1 is provided with a ventilating supporting plate 2, and the side end of the venting supporting plate 2 is provided through a throttle valve 3 through the The air inlet 4 of the inner cavity of the sorting barrel 1, the breathable supporting plate 2 is connected downward to the supporting plate rotating device 5, and the bottom end of the breathable supporting plate 2 is provided with a stirring device vertically extending into the inner cavity of the sorting barrel 1 6. The upper part of the stirring device 6 above the stirring device 6 that extends into the inner cavity of the sorting barrel 1 is rotated and stirred to form a suspension cavity 7. The suspension cavity 7 penetrates upwards into the inner cavity of the cyclone separator 8, and it penetrates downwards. At the coarse shavings outlet 9 , the air outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com