Method for plane segmented approximation of arc

A technology of plane segment and arc, applied in the field of sheet metal processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] As described above, the method for approaching a circular arc by plane segmentation, the difference of this embodiment is that the method performs arbitrary segmentation on a plane or a straight line, and uses the chord angle theorem to establish the relative bending angle mathematics between adjacent segmentation segments. model, and then use the law of cosines to calculate the angle between the split node and the end of the plane or straight line or other split nodes relative to the adjacent segment, and then calculate the angle between the split node and the end of the plane or straight line or the other split nodes Length, and finally calculate the height of the end of the plane or line or other segmented nodes relative to the initial position of the plane or line, and use this height as the basis for approximating the arc.

[0059] Compared with other arc approximation methods, the present invention has the advantage of providing a method based on the relative displ...

Embodiment 2

[0061] As described above, the method for approaching a circular arc by plane segments, the difference of this embodiment is that the implementation of the method for approaching a circular arc by plane segments according to the present invention is realized through the following steps:

[0062] Step 1: Divide the plane or straight line arbitrarily to obtain the length of each segment.

[0063] Step 2: Calculate the relative bending angles between adjacent segments.

[0064] Step 3: According to the relative bending angle of the adjacent segment and the cosine law, calculate the angle between the segment node and the end of the plane or the line connecting the other segment nodes with respect to the adjacent segment.

[0065] Step 4: Use the law of cosines to calculate the length of the connecting line between the split node and the end of the plane or straight line or other split nodes.

[0066] Step 5: According to the calculation results of steps 3 and 4, finally calculate...

Embodiment 3

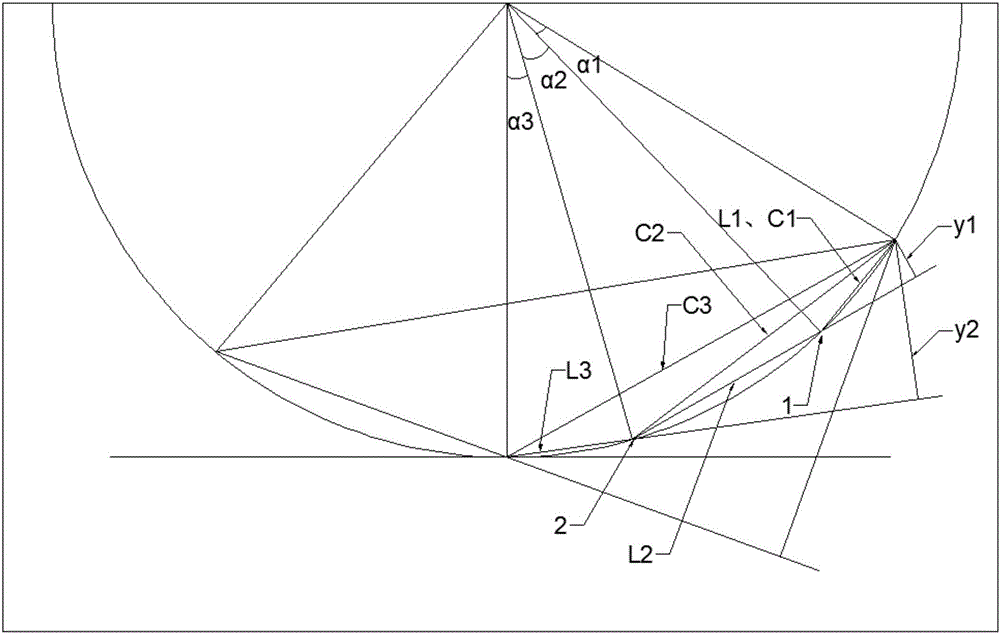

[0070] As mentioned above, the method for approaching a circular arc by plane segments, the difference of this embodiment is that the implementation of the present invention is divided into five steps. Curvature, and then divide the plane or straight line according to the given division method, and then calculate the displacement of the end of the plane or straight line and each division point relative to the initial position after each bending, as the basis for approximating the arc, as shown in the attached figure 1 shown.

[0071] Step 1: As attached figure 1 As shown, the plane or straight line is arbitrarily divided into n parts, and the length of each part is L 1 , L 2 , L 3 …L n , the central angle corresponding to each part is α 1 、α 2 、α 3 …α n , then there are n-1 split nodes after splitting.

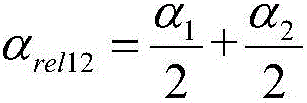

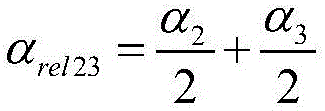

[0072] Step 2: Calculate the relative bending angle between adjacent segments by using the chord cut angle theorem, that is, the sum of the circumferential angles of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com