Duplex gear positioning and centering fixture

A double gear and centering fixture technology, which is applied in gear tooth manufacturing devices, belts/chains/gears, gear teeth, etc., can solve the problems of low accuracy, lack of mass production, low efficiency, etc., and achieve mass production The effect of production and rapid positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

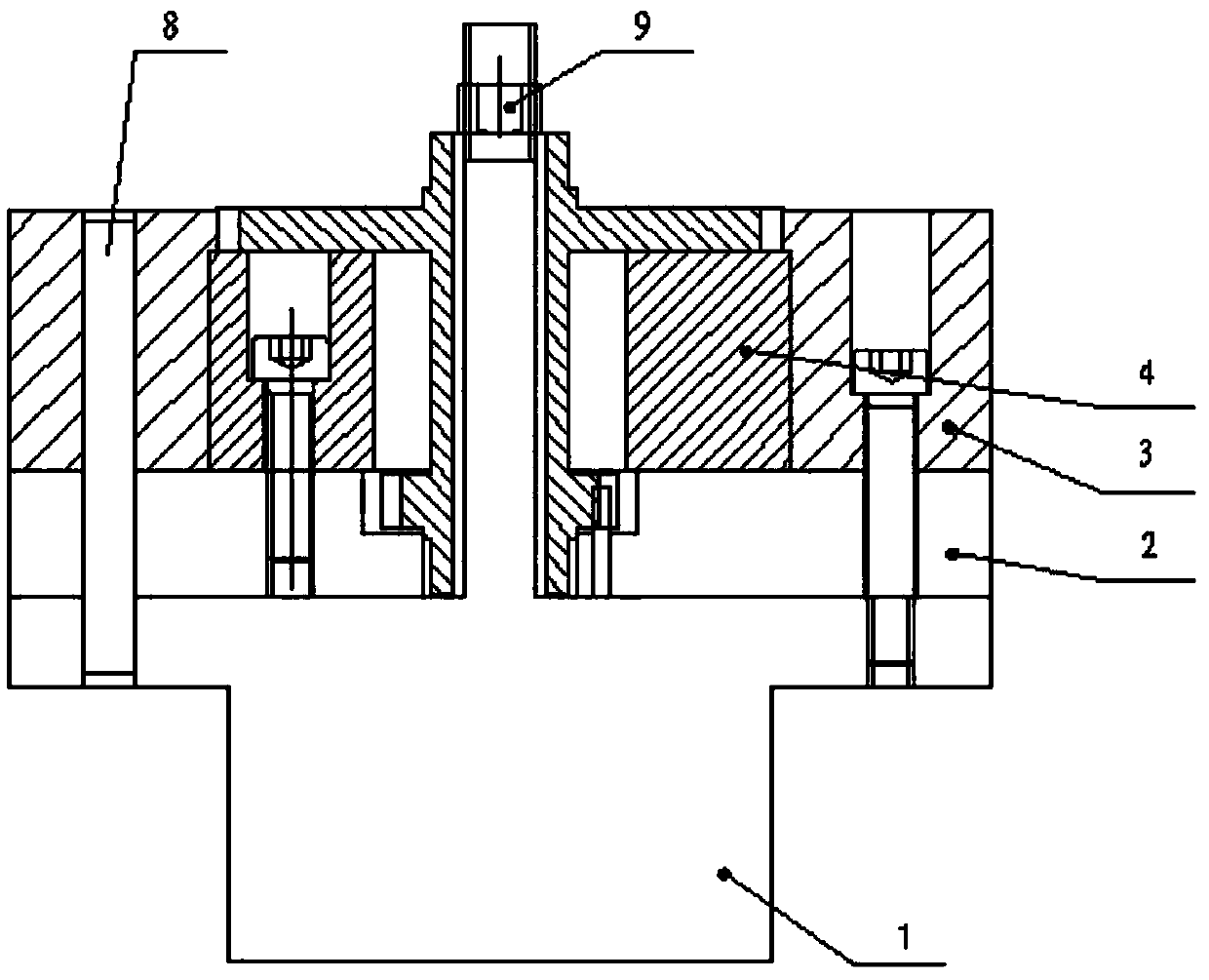

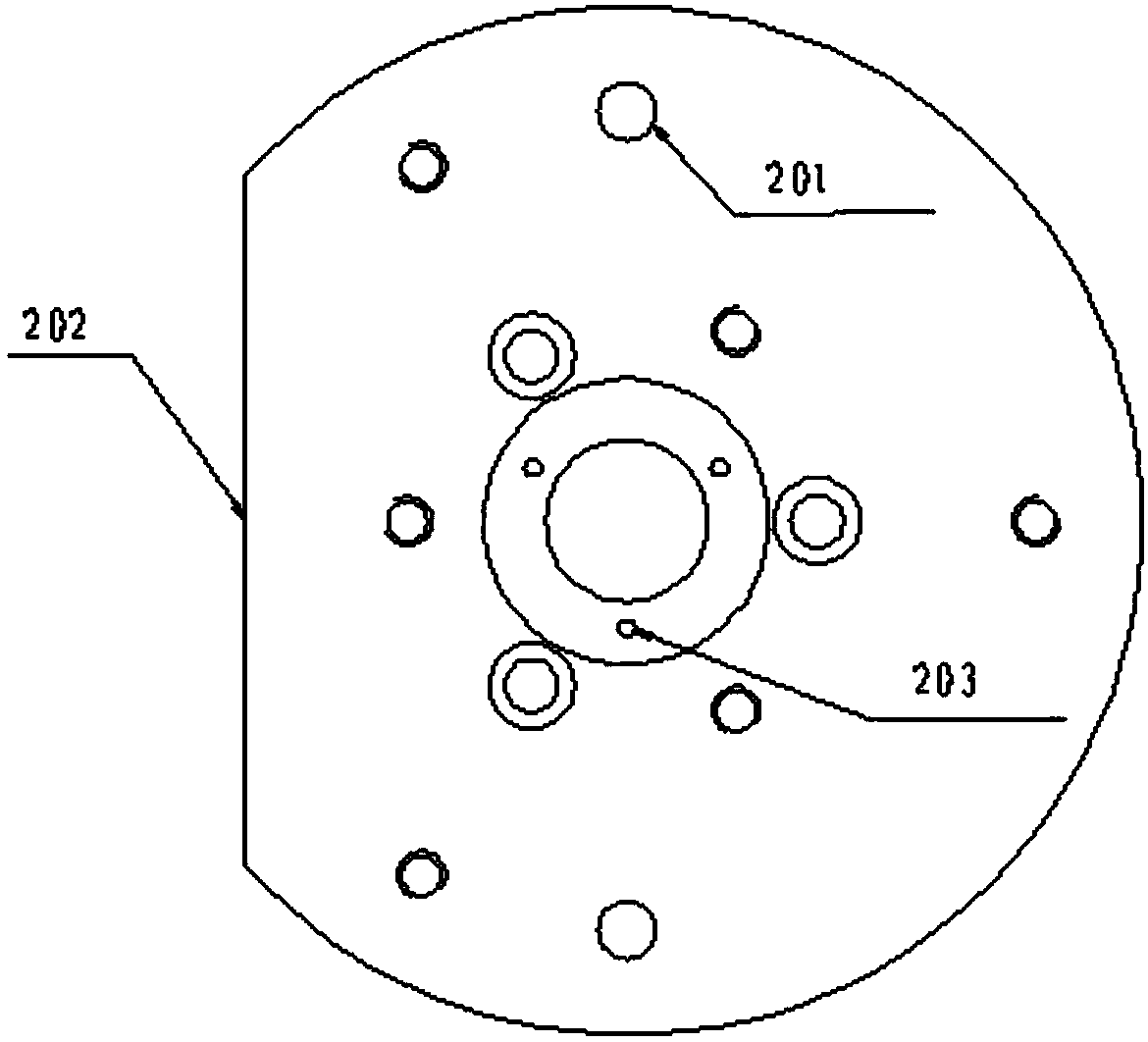

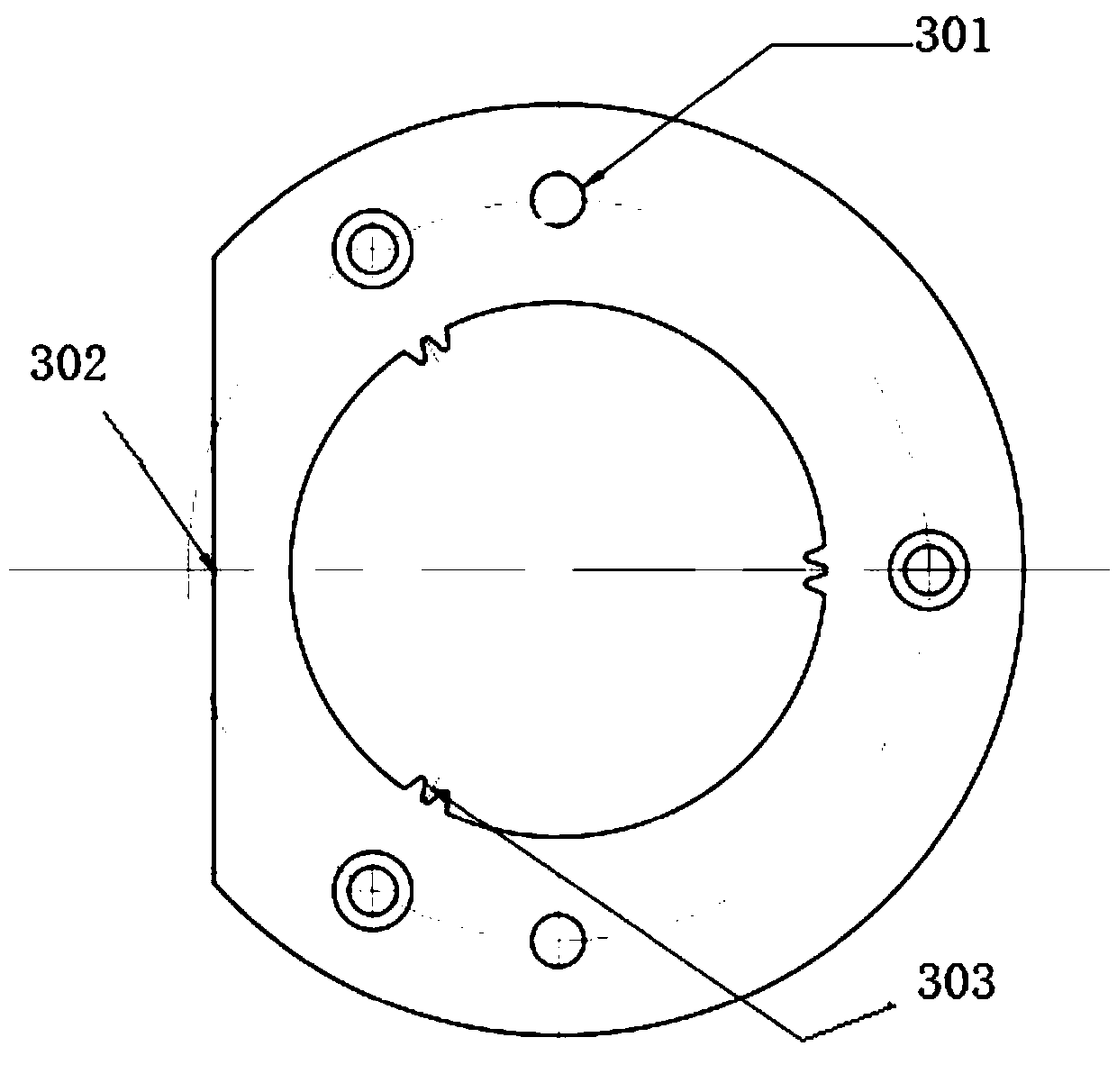

[0021] figure 1 It is the first embodiment of the device of the present invention, where the positioning teeth of the center hole of the large gear positioning piece are positioned with the large gear of the double gear, and the pinion positioning piece is set as the positioning taper pin and the pinion of the double gear for positioning, and the double gear is processed. When the large end face of the gear is connected, the fastener 9 is a bolt, the pinion positioning piece 2 in the positioning device is located on the boss of the mandrel 1, and the axial positioning block 4 is arranged on the pinion positioning piece 2 and positioned on the large gear positioning piece. In the central hole 304 of the piece 3, and connected with the pinion positioning piece 2, the large gear positioning piece is provided with a pin hole 301, and the pinion positioning piece is provided with a pin hole 201, and three groups of positioning teeth 303 are uniformly arranged in the large gear posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com