Integrated front end cooling module for vehicle

A cooling module and integrated technology, which is applied to the layout of the cooling combination of the power unit, vehicle components, power units, etc., can solve the problem of the decline of the cooling performance of the vehicle air-conditioning system, the reduction of the heat dissipation effect of the condenser, and the low heat exchange efficiency of the cooling part, etc. problems, to avoid adverse effects, improve cooling efficiency, and make full use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

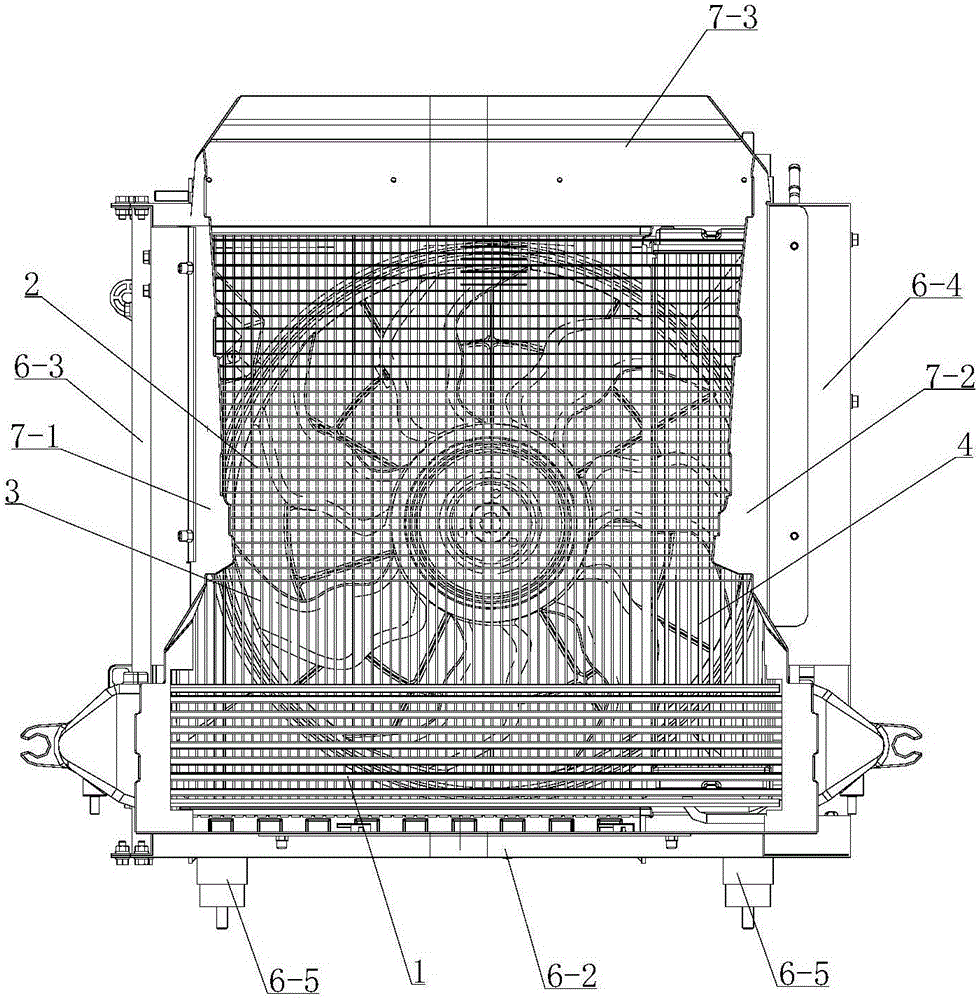

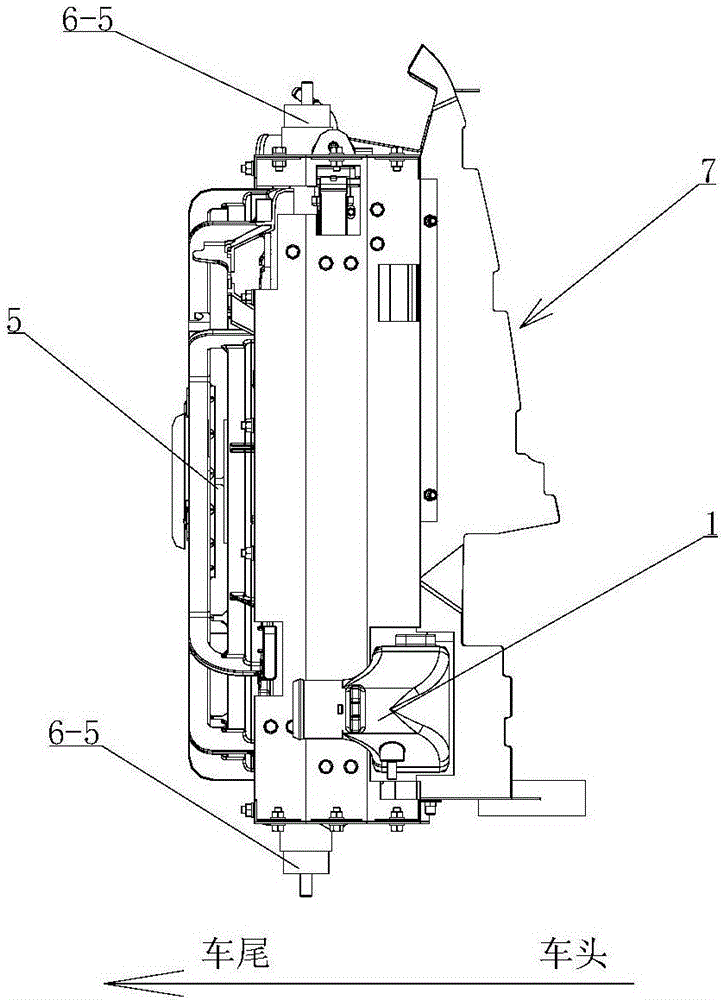

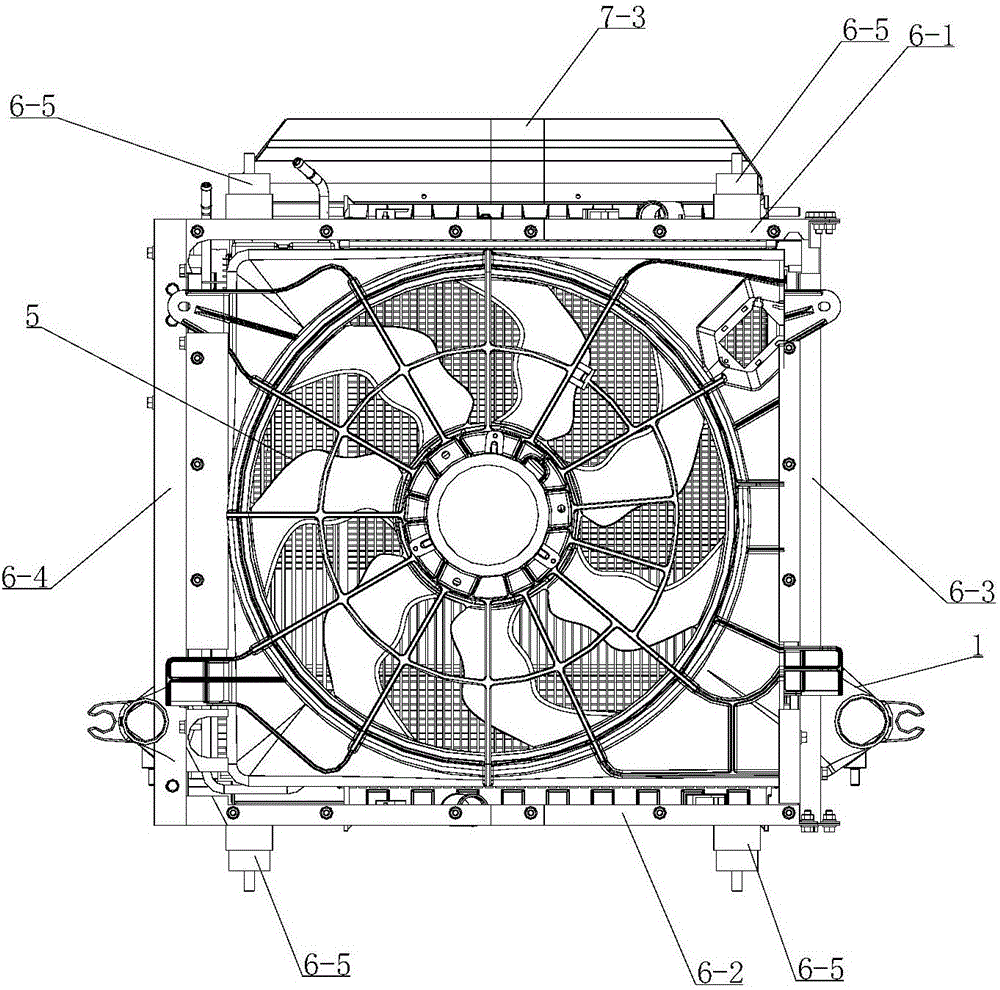

[0030] see Figure 1-8 , an integrated front-end cooling module for vehicles, including an intercooler 1, a condenser 2, a radiator 2, an oil cooler 4, a cooling fan 5, and a mounting frame 6. The installation frame is composed of an upper frame edge 6-1, a lower frame edge 6-2, a left frame edge 6-3 and a right frame edge 6-4, and a positioning frame is respectively arranged on the upper and lower frame edges near both ends. Column 6-5, the installation frame forms a connection with the surrounding sheet metal structure through four positioning columns. Along the direction from the front of the vehicle to the rear of the vehicle, the installation frame is divided into a front installation area, a middle installation area and a rear installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com