A new type of steel pressing device

A new type of steel technology, applied in transportation and packaging, unstacking of objects, stacking of objects, etc., can solve the problems of falling on the finished product stand, short retention period, difficult to achieve, etc., to achieve accurate rotation angle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

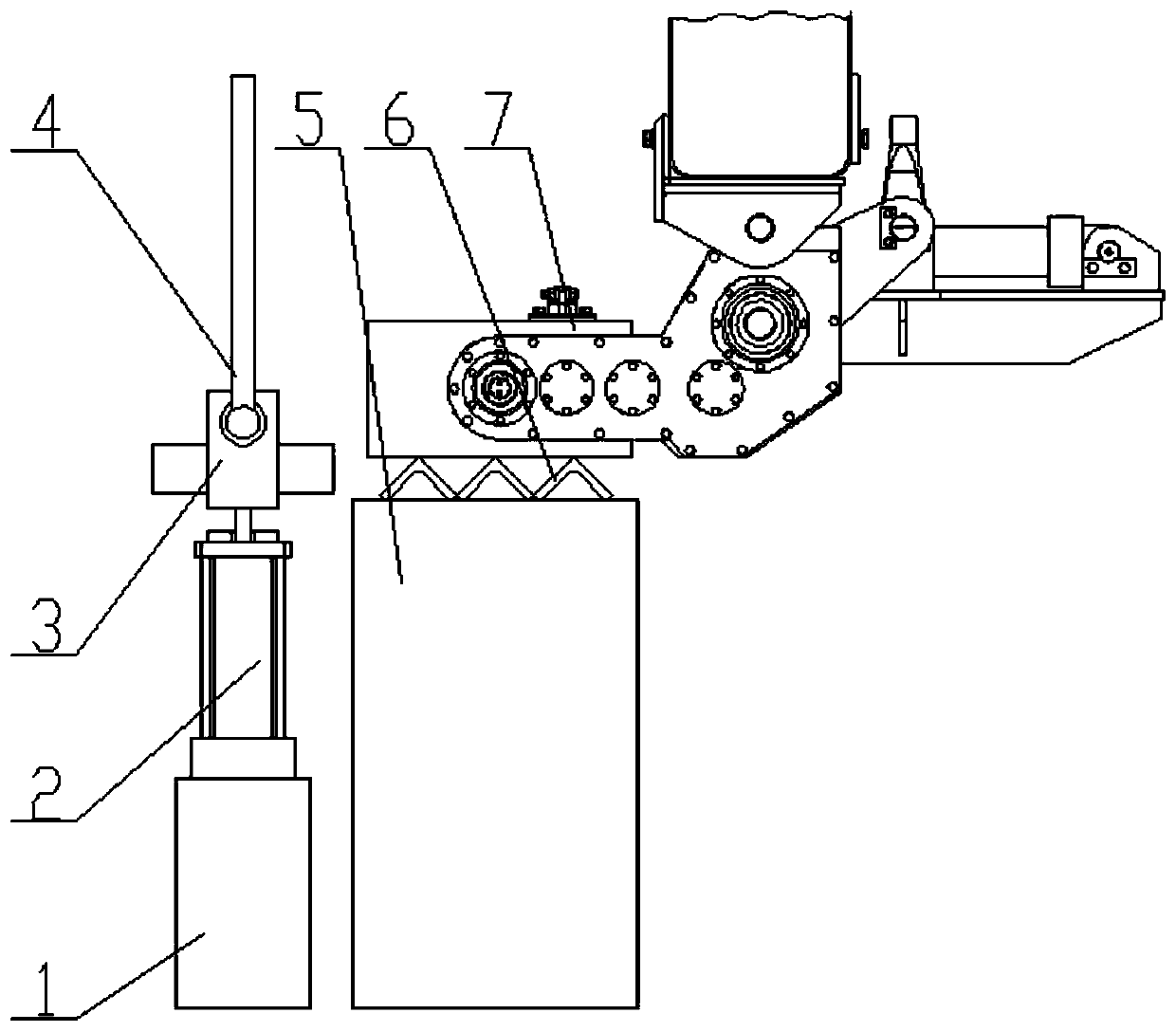

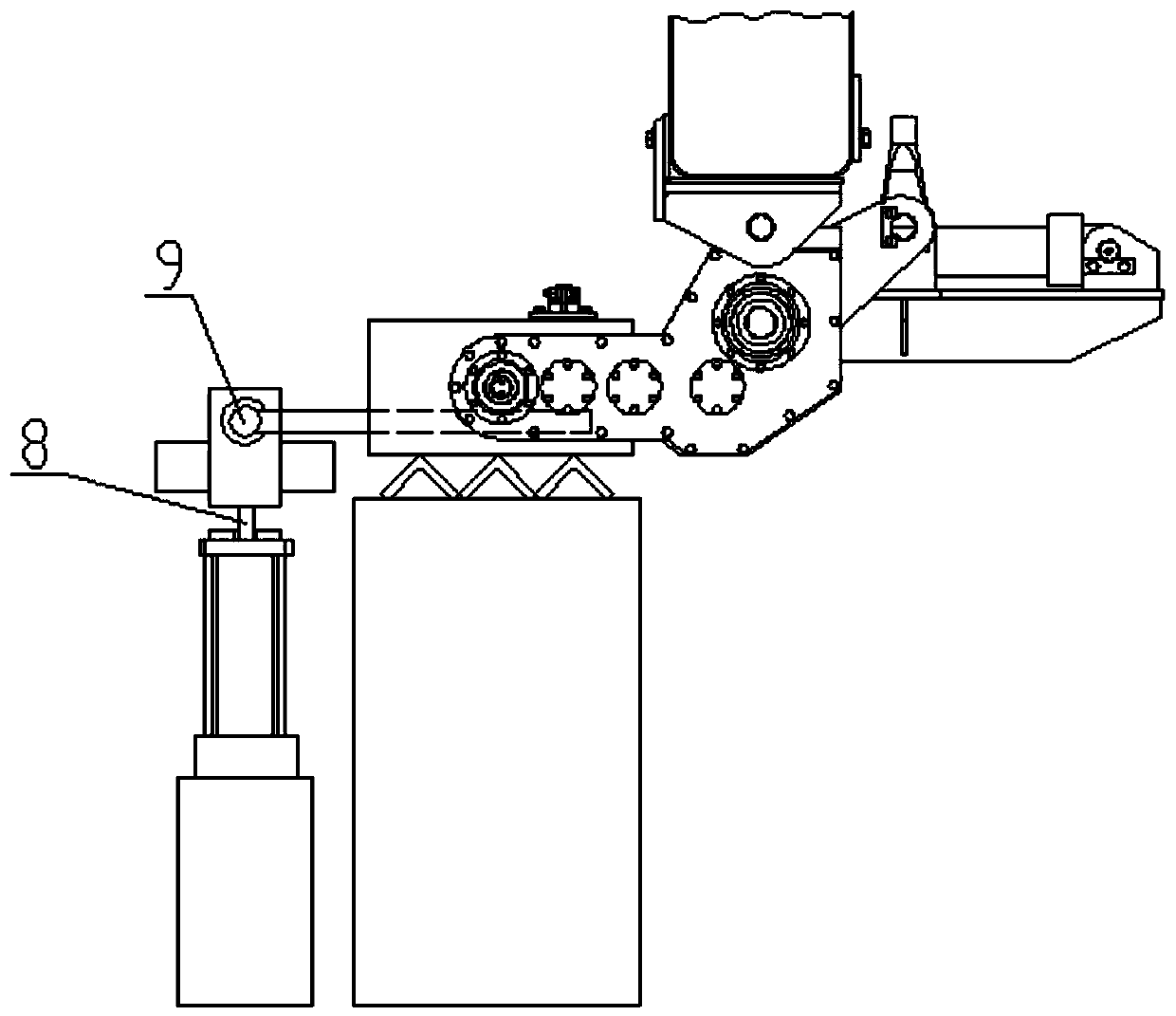

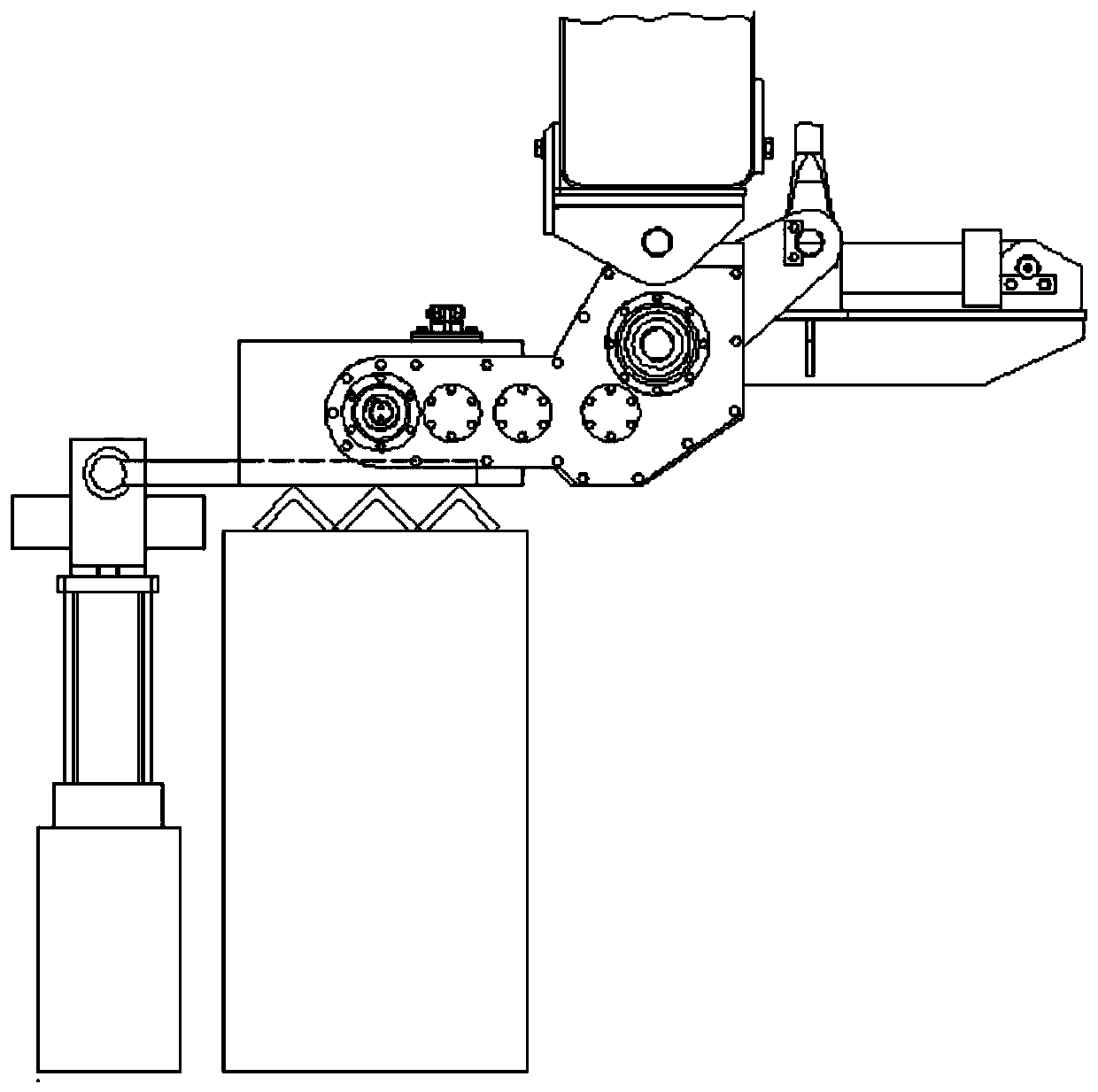

[0026] The present invention is a novel steel pressing device, comprising a base, a pressing plate for pressing steel, a rotating device for rotating the pressing plate and a lifting device for raising or lowering the pressing plate; the lifting device includes a The lifting mechanism and the first controller connected to the lifting mechanism are controlled vertically; the swing cylinder is arranged on the lifting rod of the lifting mechanism, and the rotating device includes a swing cylinder and a first controller connected to the swing cylinder. Two controllers, the output shaft of the swing cylinder is parallel to the section steel along the horizontal direction; the pressure plate is fixedly connected to the output shaft of the swing cylinder, and the length direction of the pressure plate is perpendicular to the output shaft of the swing cylinder. The swing cylinder drives the pressing plate to rotate in the vertical plane.

[0027] to combine figure 1 — Figure 5 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com