Three-dimensional direction carrying hanging tool

A spreader, three-dimensional technology, applied in the field of three-dimensional direction handling spreader, can solve the problems of increased production cost, high labor intensity, low operation efficiency, etc., and achieve the goal of reducing labor cost, reducing labor intensity, and improving transshipment efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

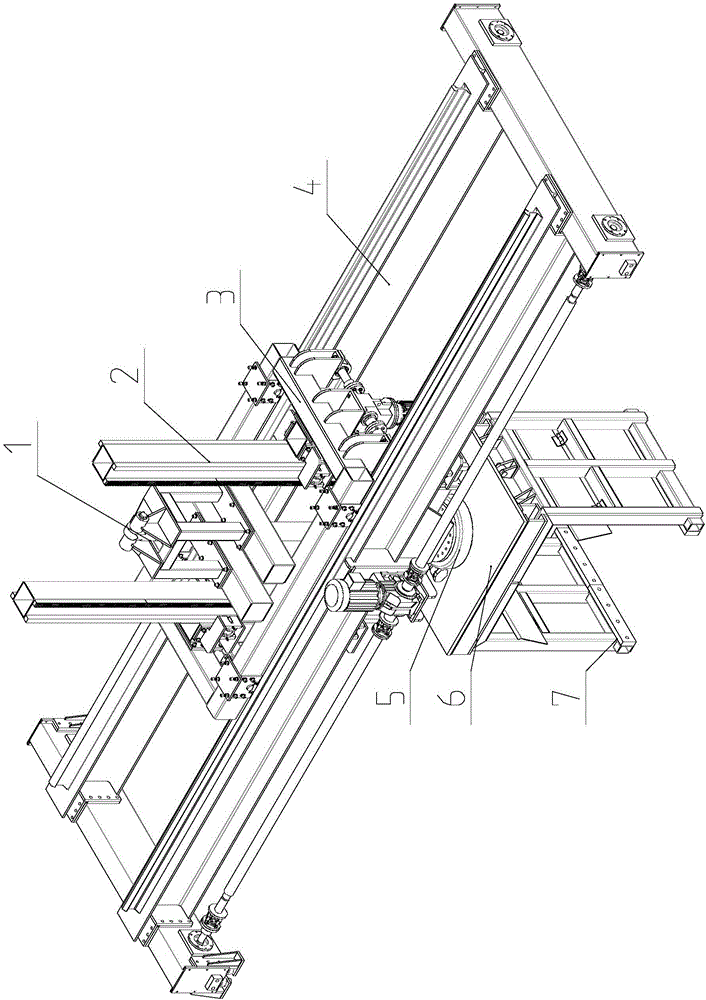

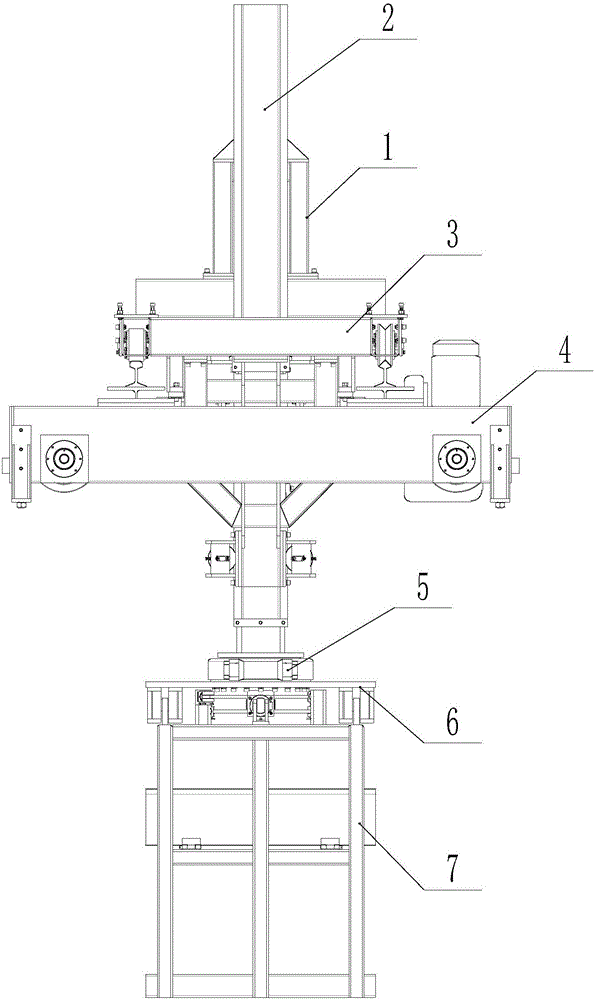

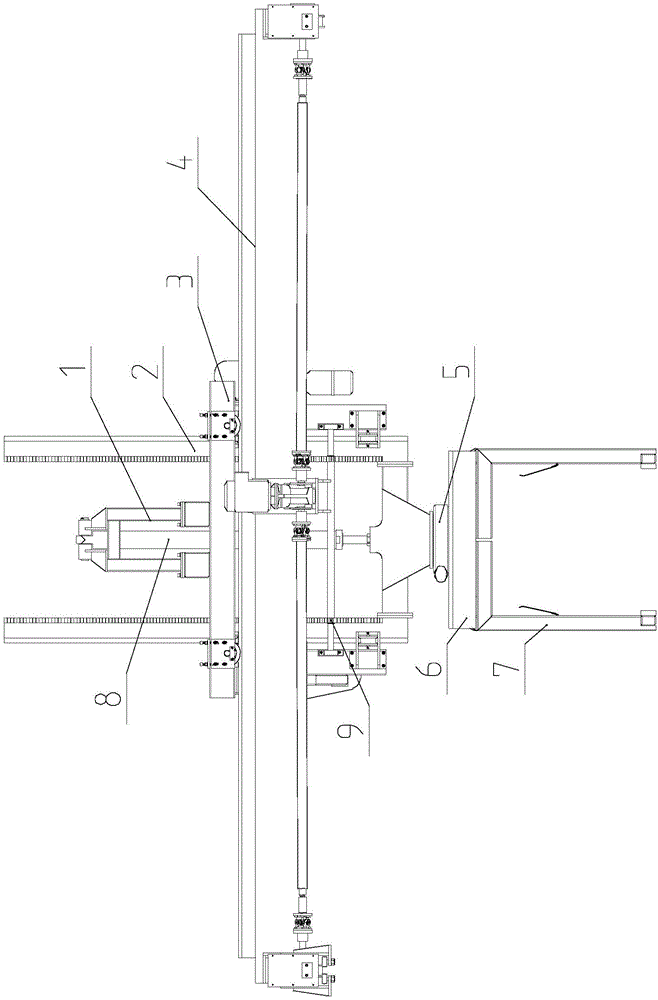

[0015] Embodiment 1: A three-dimensional direction handling spreader, including jaws 7, also includes lifting cylinder base 1, lifting beam 2, trolley 3, driving 4, rotary motor 5, clamping arm 6, wherein lifting cylinder 8 is connected with lifting cylinder respectively The seat 1 and the lifting beam 2 are connected, the lifting cylinder seat 1 and the lifting beam 2 are installed on the trolley 3, the jaw 7 is connected with the clamp arm 6, the clamp arm 6 is connected with the lifting beam 2 through the rotary motor 5, and the trolley 3 moves Set on the upper track of the carriage 4. Both sides of the slewing motor 5 are provided with a lifting beam 2 , and the trolley 3 is also provided with a lifting beam guiding mechanism, and the lifting beam 2 passes through the lifting beam guiding mechanism and is connected with the lifting cylinder 8 . The lifting beam 2 is provided with a guide wheel guiding mechanism, and a synchronous lever 9 is also provided on the trolley 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com