A method and device for producing diammonium phosphate from wastewater containing nitrogen and phosphorus

A technology of diammonium phosphate and monoammonium phosphate, which is applied in the directions of phosphate and phosphorus oxyacid, can solve the problems of large waste of resources, high environmental protection treatment costs, and insufficient recycling of nitrogen and phosphorus, so as to improve recycling and utilization. rate, the effect of achieving water balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

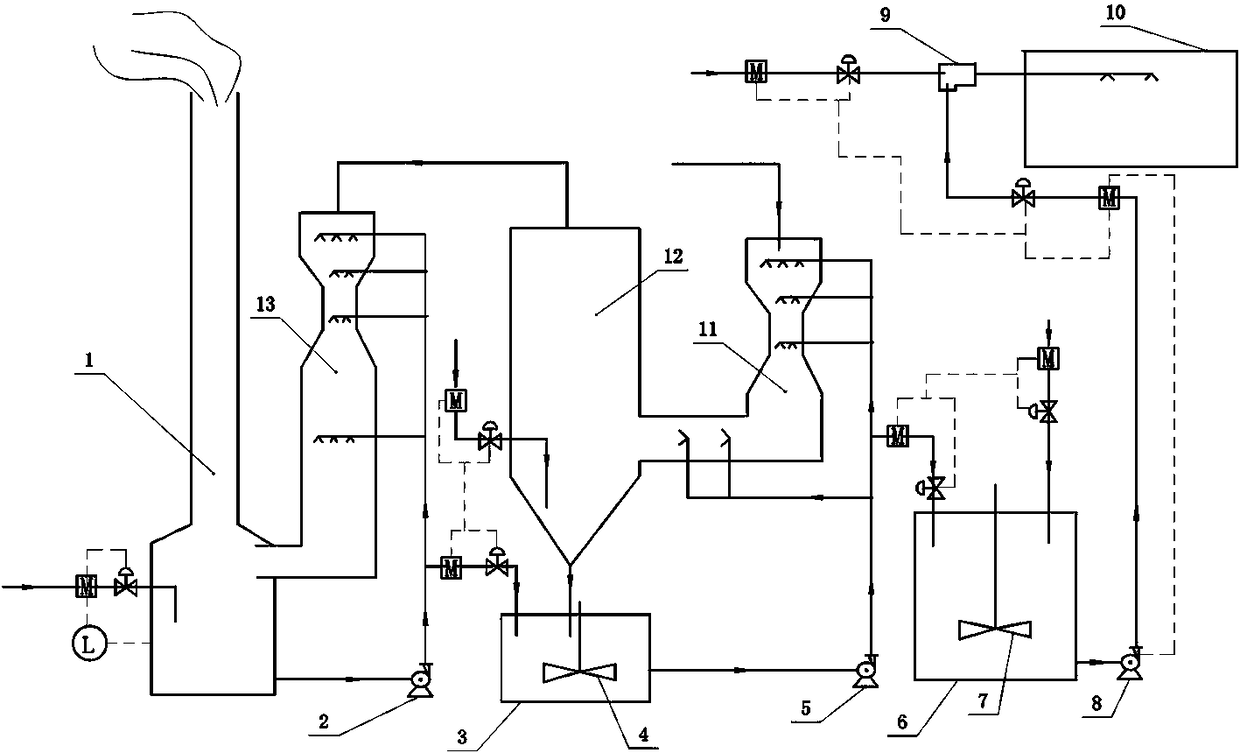

[0022] As shown in the figure, the present invention will be further described in conjunction with the accompanying drawings:

[0023] Adopt the present invention to produce diammonium phosphate product as diammonium lotion by reclaiming nitrogen-containing phosphorus waste water, concrete scheme is as follows:

[0024] The specific steps are as follows:

[0025] 1. Send nitrogen and phosphorus-containing waste water to the tail gas scrubber 1 of diammonium phosphate, and circulate through the tail washing circulation pump 2 in the tail washing Venturi scrubber 13 to wash and absorb the tail gas of the diammonium plant.

[0026] 2. The tail gas washing circulating liquid is transported to the scrubber tank 3 through the tail gas washing pump 2, the concentrated phosphoric acid and the tail washing circulating liquid are interlocked and added into the scrubber 12, and the concentrated phosphoric acid and the tail washing circulating liquid are separated under the agitation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com