A kind of wet scraper slag fishing machine water level balance control method

A technology of water level balance and control method, applied in liquid level control, electric controller, control/regulation system, etc., can solve the problems of large water level fluctuation, unstable operation of desulfurization wastewater system, unfavorable safe and stable operation of slag machine, etc. To achieve the effect of no overflow water level balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

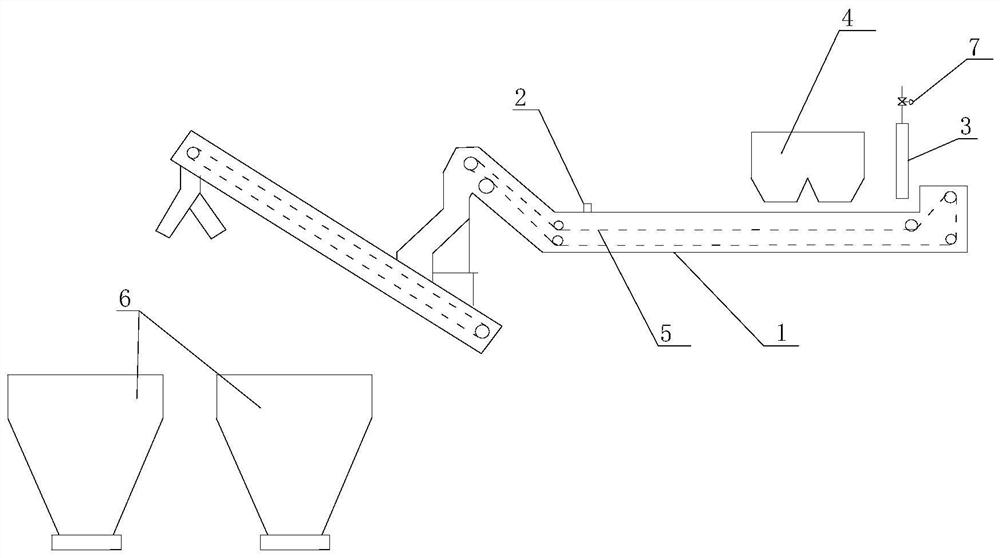

[0034] refer to figure 1 , before describing the method of the present embodiment, the structure of the slag removal machine is described first, and the details are as follows:

[0035] The slag removal machine includes a casing 1 , a liquid level gauge 2 for detecting the liquid level in the casing 1 , a water supply pipe 3 for supplementing desulfurization wastewater into the casing 1 , and a slag drop port 4 arranged above the casing 1 . , The scraper unit 5 driven by the chain, the slag bin 6 arranged on the outside of the casing 1 for receiving the solid output from the scraper unit 5, the water supply pipe 3 is provided with a control valve 7; the scraper unit 5 extends to The bottom of the shell 1 is used to transport the solids in the shell 1 to the slag bin 6 .

[0036] It should be noted that the scraper unit 5 is commonly used in the art, and is driven by a chain, and a plurality of scrapers are arranged on the chain.

[0037] This slag removal machine can be rega...

Embodiment 2

[0056] The following describes in detail with specific examples:

[0057] The parameters of the boiler involved in this example are: Shanghai Boiler Factory, 600,000 MW boiler;

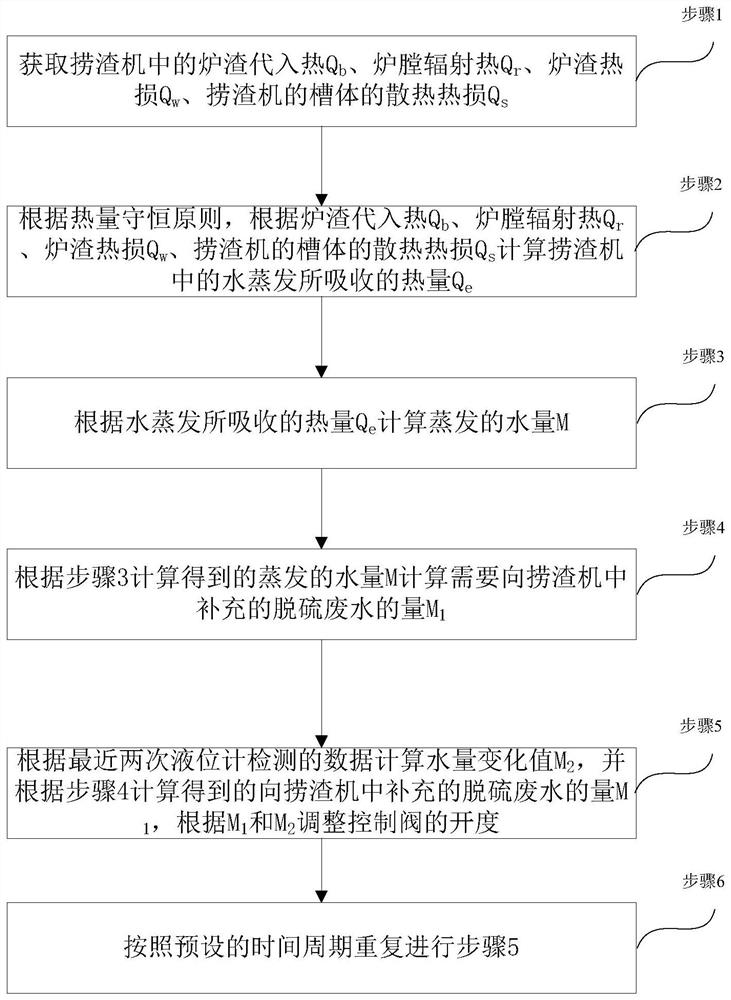

[0058] According to the law of conservation of energy: input heat = output heat.

[0059] Input heat: slag substitution heat, radiant heat of furnace (system friction heat is not counted).

[0060] Output heat: water evaporation absorbs heat, slag heat loss and heat dissipation heat loss.

[0061] Refer to Table 1-5 for details.

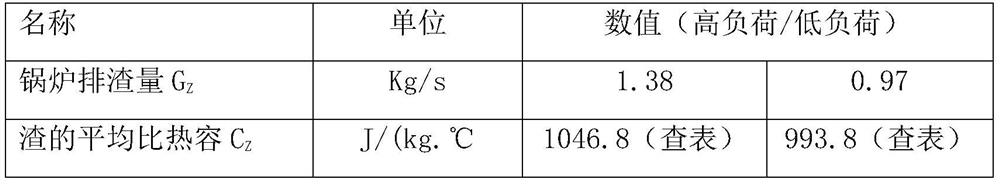

[0062] 1.1 Slag substitution heat

[0063] Table 1 Slag substitution heat calculation parameter table

[0064]

[0065]

[0066] Based on Table 1, slag substitution heat Q b =G Z ×C Z ×(T z -T 1 ) = 1141221.36(W);

[0067] 1.2 Radiant heat of furnace

[0068] Table 2 Calculation parameters of furnace radiant heat

[0069]

[0070] Based on Table 2, the furnace radiant heat Qr=F t ×C 0 ×φ 12 ×ε 1 ×ε 2 ×(t b -T 1 ) = 30573(w);

[0071] 1.3 Water ev...

Embodiment 3

[0090] Based on the statistics and calculation results of Example 2, combined with the built-in liquid level gauge of the slag removal machine, the opening degree of the control valve can be controlled more accurately.

[0091] Take an example to illustrate: the current working condition is a high load state.

[0092] If the test cycle of the liquid level gauge is once every 10 minutes, then at the 0th minute, the liquid level obtained by the test is h 1 ; At the 10th minute, the liquid level obtained by the test is h 2 ;

[0093] If the calculation result of Embodiment 2 is absolutely accurate, the liquid level in the shell of the slag scraper is controllable and unchanged at any time.

[0094] However, there is always a deviation between the calculation and the actual value. Based on the calculation result of Example 2, the deviation can be controlled within 50mm of the liquid level fluctuation.

[0095] In order to avoid the overall failure of the system caused by the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com