A kind of preparation method of chromatographic grade methyl tertiary butyl ether

A technology of methyl tertiary butyl ether and chromatographic grade, applied in the field of preparation of chromatographic grade methyl tertiary butyl ether, can solve the problems of complicated operation steps and high cost, and achieve the effects of classic process, easy operation and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

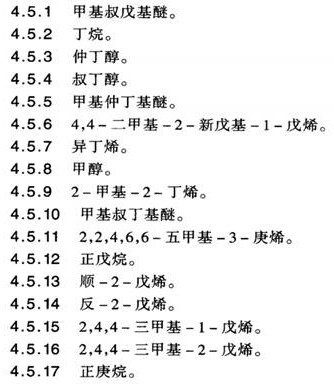

Image

Examples

Embodiment 1

[0024] (1) In a 5L three-neck flask with stirring, condensation and thermometer, under nitrogen protection, put 3 liters of industrial grade methyl tert-butyl ether (about 2220g) and 120g of sodium hypochlorite solution, heat, stir and reflux for 2 hours to generate chlorohydrins, And under alkaline hydrolysis to generate diol soluble in water;

[0025] (2) Cool the mixture of the reactants of industrial-grade methyl tert-butyl ether and sodium hypochlorite solution in step (1) to below 10°C, let it stand for 0.5 hours, and separate the phases; the water phase is used for wastewater treatment;

[0026] (3) Add 240g of anhydrous calcium oxide to the organic phase, and dry it under ultrasonic waves at room temperature for 1 hour;

[0027] (4) standing and microfiltration to obtain purified and dried methyl tert-butyl ether, wherein the methyl tert-butyl ether does not contain olefins and alcohols;

[0028] (5) Under the protection of nitrogen, add dry methyl tert-butyl ether in...

Embodiment 2

[0031] (1) In a 5L three-necked flask with stirring, condensation and thermometer, under the protection of nitrogen, put 3 liters of industrial grade methyl tert-butyl ether (about 2220g) and 200g of sodium hypochlorite solution, heat, stir and reflux for 1 hour to generate chlorohydrins, And under alkaline hydrolysis to generate diol soluble in water;

[0032] (2) Cool the mixture of the reactants of industrial-grade methyl tert-butyl ether and sodium hypochlorite solution in step (1) to below 10°C, let it stand for 0.5 hours, and separate the phases; the water phase is used for wastewater treatment;

[0033] (3) Add 180g of anhydrous calcium oxide to the organic phase, and dry it under ultrasonic wave at room temperature for 1 hour;

[0034] (4) standing and microfiltration to obtain purified and dried methyl tert-butyl ether, wherein the methyl tert-butyl ether does not contain olefins and alcohols;

[0035] (5) Distill the dried methyl tert-butyl ether through a rectifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com