Patents

Literature

31results about How to "Suitable for large-scale operation" patented technology

Efficacy Topic

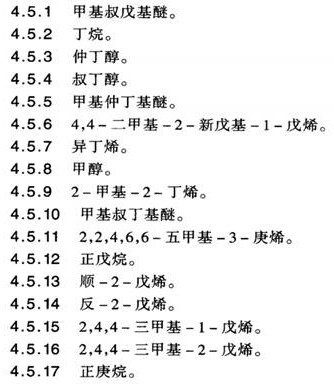

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

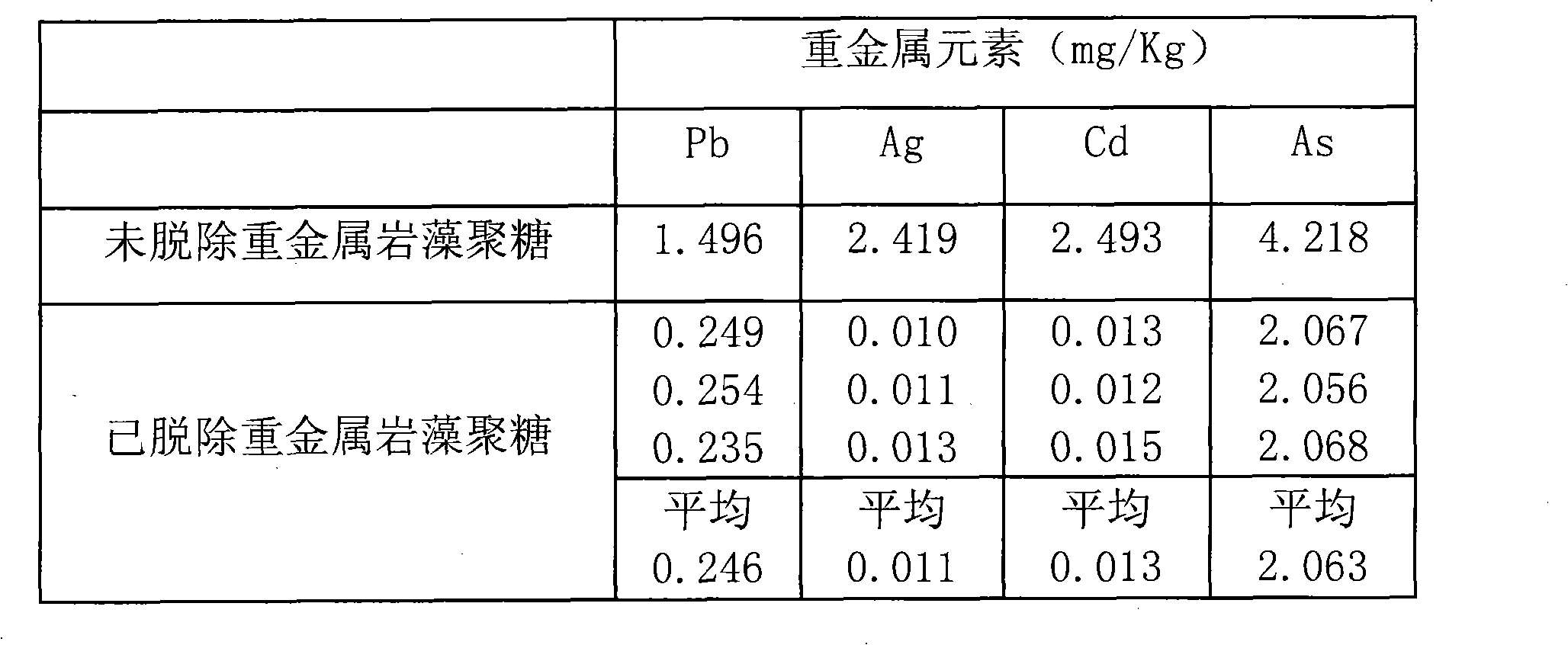

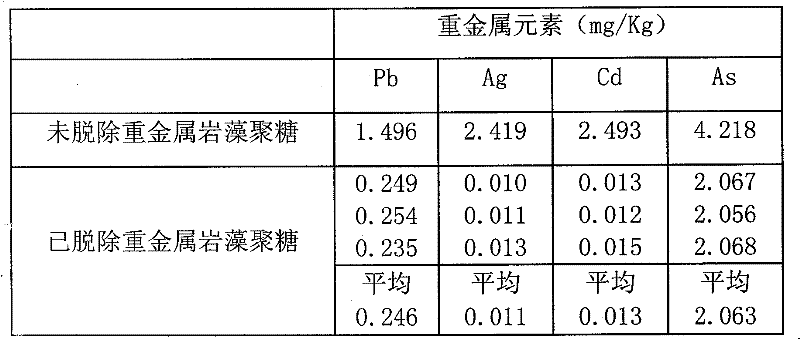

Preparation method of fucosan

The invention discloses a preparation method of fucosan. On the basis of the traditional preparation technology of the fucosan, HCl is adopted to adjust the pH value of solution, and metal chelating agent EDTA is added, so as to lead heavy metal ions originally chelated on the fucosan sulfate groups to shed off and form chelates with the EDTA. By adopting an ultrafiltration technology, the EDTA-heavy metal chelates are separated from the fucosan, and concentrated, and the fucosan after the removal of heavy metal elements can be prepared through freeze-drying. The preparation method has the advantages of simple operation, mild conditions, high shedding rate of heavy metal ions, low cost and the like, and is suitable for large-scale operations.

Owner:JIMEI UNIV

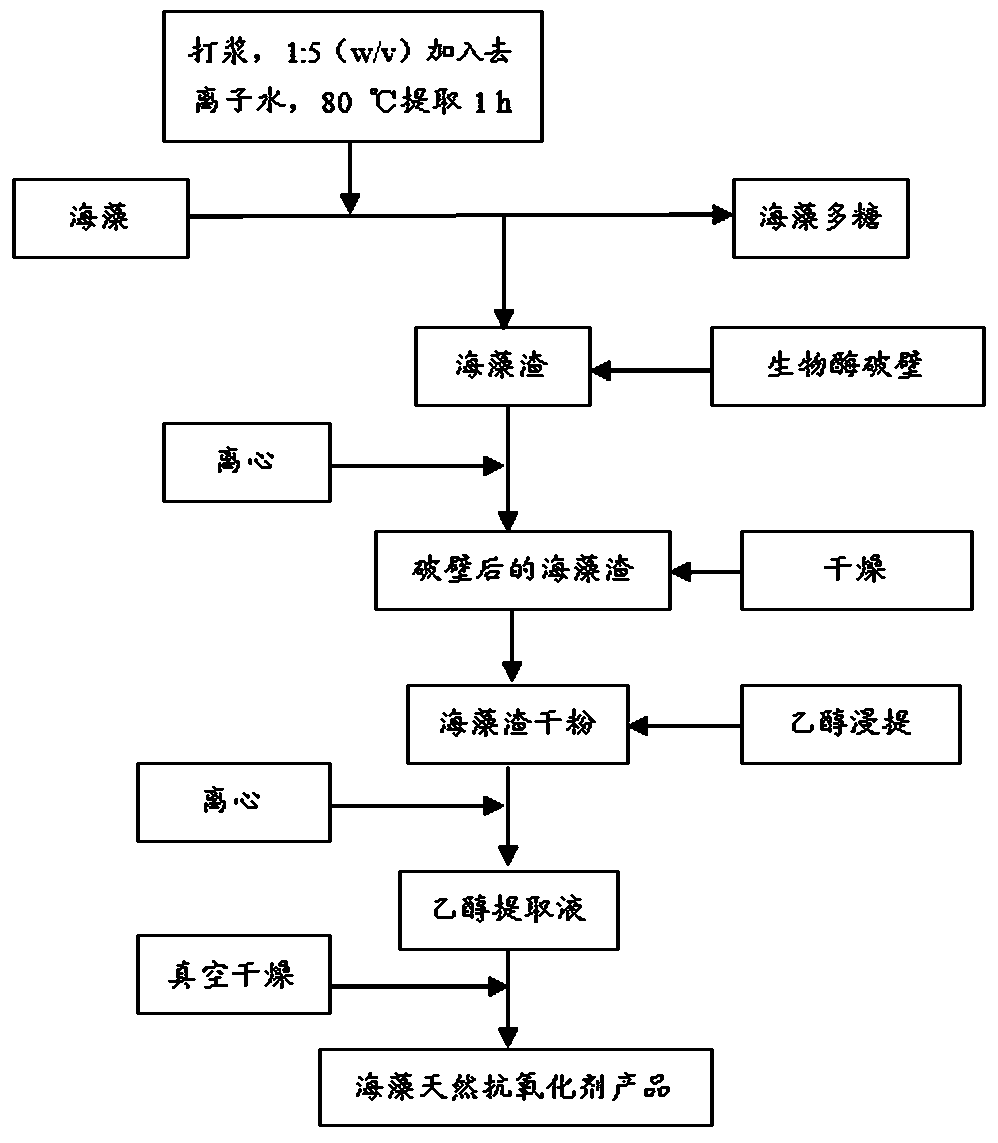

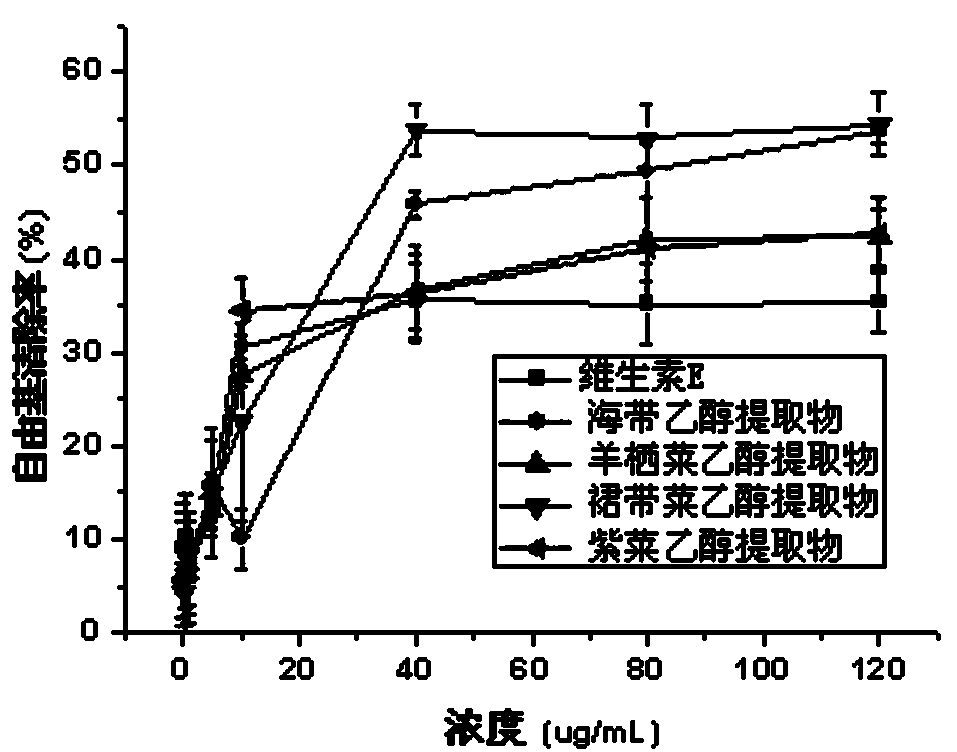

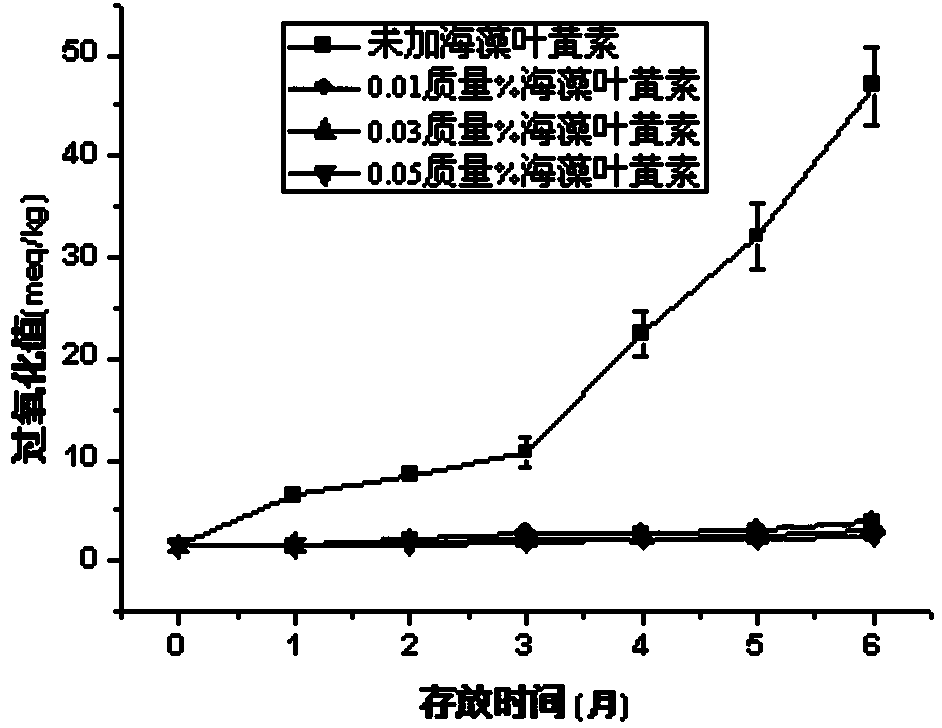

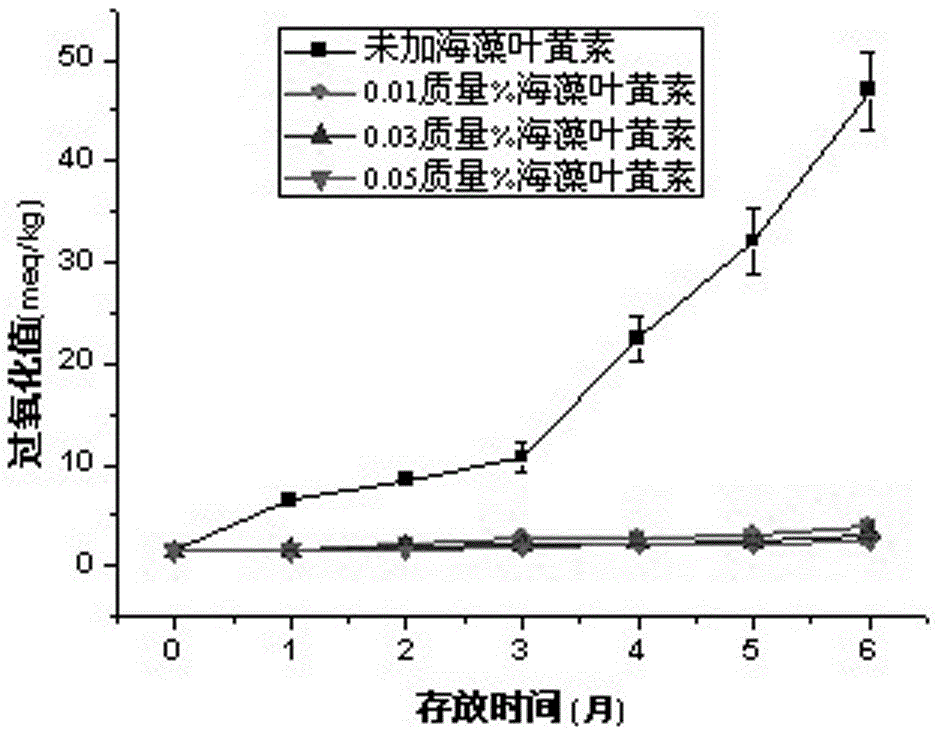

Preparation method of alga natural antioxidant

InactiveCN104001180AAbundant resourcesHigh content of antioxidant active substancesFood preservationPharmaceutical non-active ingredientsChemical synthesisPhenol

The invention discloses a preparation method of an alga natural antioxidant. The preparation method is as follows: beating and crushing fresh alga, extracting with hot water, centrifuging, drying, crushing, sieving to obtain alga residue, further using a biological enzyme method for broking wall to obtain wall-broken alga residue dry powder; using food grade absolute ethanol for extraction at room temperature, collecting an extracting solution, and performing decompression concentration and vacuum drying to obtain the natural algae antioxidant product. The natural algae antioxidant product is paste, and comprises 5.2 to 13.7 by mass% of total phenol, 3.6 to 8.4 by mass% of total carotenoids, 0.5 to 1.3 by mass% of terpenoids and 0.9 to 2.6 by mass% of sterol compounds. The preparation method adopts the alga residue as a raw material to prepare the natural antioxidant with strong antioxidant activity, realizes the comprehensive utilization of resources, is in simple, efficient, green and environmentally friendly in the production process, and is suitable for industrial production; the natural algae antioxidant product is strong in antioxidant capacity, natural and green, and can replace traditional chemical synthesized antioxidants to use in food industry.

Owner:JIMEI UNIV

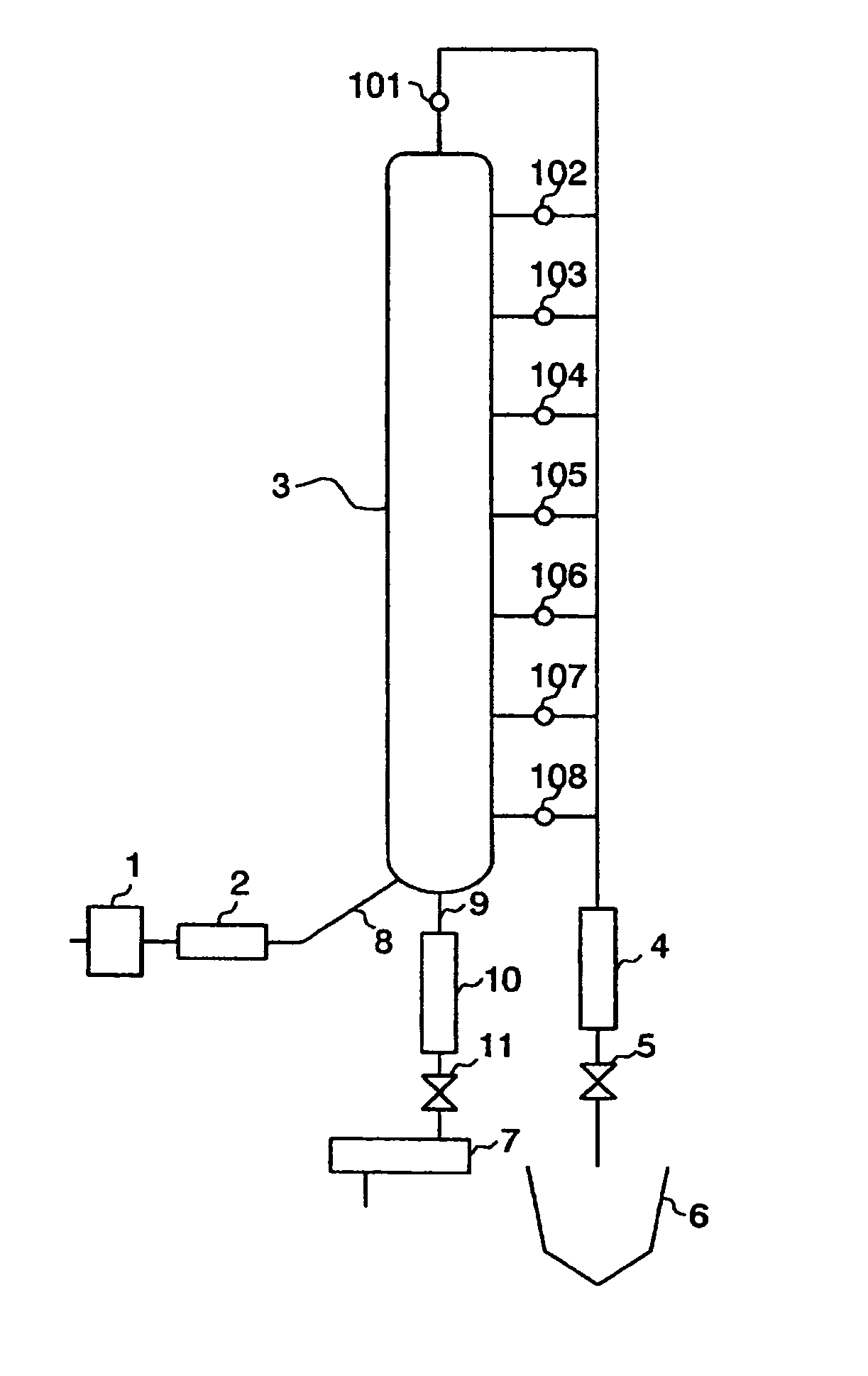

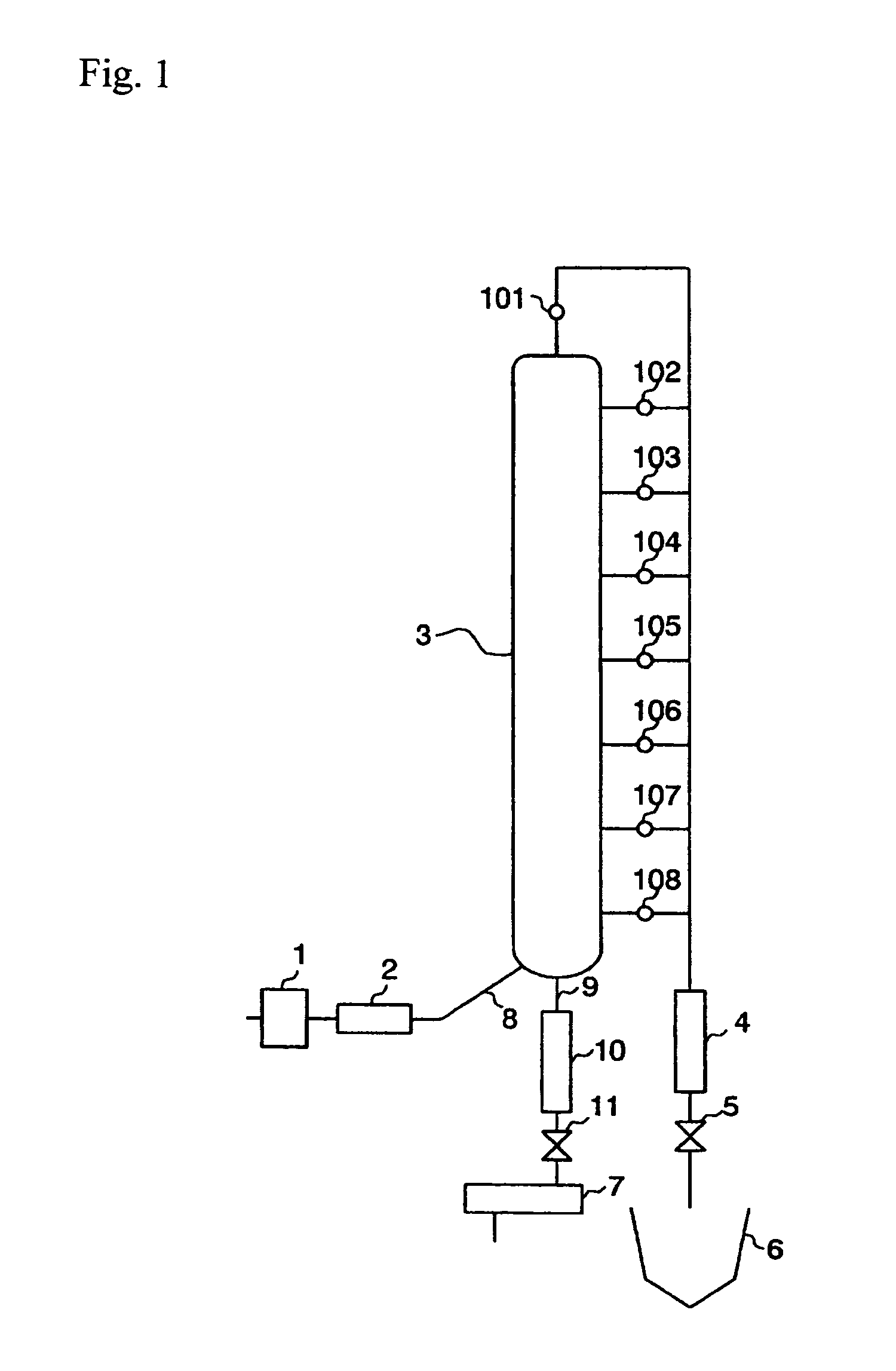

Method of and apparatus for producing sub-critical water decomposition products

InactiveUS20070160524A1Suitable for large-scale operationReduce equipment costsSludge treatment by oxidationSolid waste disposalFluidized bedDecomposition

[Problems] A method of and an apparatus for continuous sub-critical water decomposition treatment for material to be processed containing solid matter are provided, which are capable of controlling decomposition reaction of the material to be processed and suitable for large-scale operations. The method and the apparatus are also capable of minimizing equipment costs and selectively producing desired useful substances at high yield rates. [Means to Solve the Problems] Material to be processed is grinded in advance into particles, which are mixed with water to prepare slurry. The slurry is sent to a compressing means (1) through a pipe and is compressed. Next, the compressed slurry is sent to a heating means 2 and heated, and is brought into a sub-critical state. The slurry in a sub-critical condition is introduced through an inlet (8) into a bottom part of a reactor (3). In the reactor (3) a fixed bed, a fluidized bed, and a sub-critical water dissolution part are formed in that order from the bottom. One(s) of outlets (101) to 106 provided at top and side portions of the reactor 3 is / are selected so that the sub-critical water dissolution part is taken out therethrough, whereby the residence time of the sub-critical water is adjusted and thus the reaction time of sub-critical water decomposition of the material to be processed is adjusted.

Owner:PUBLIC UNIVERSITY CORPORATION OSAKA CITY UNIVERSITY

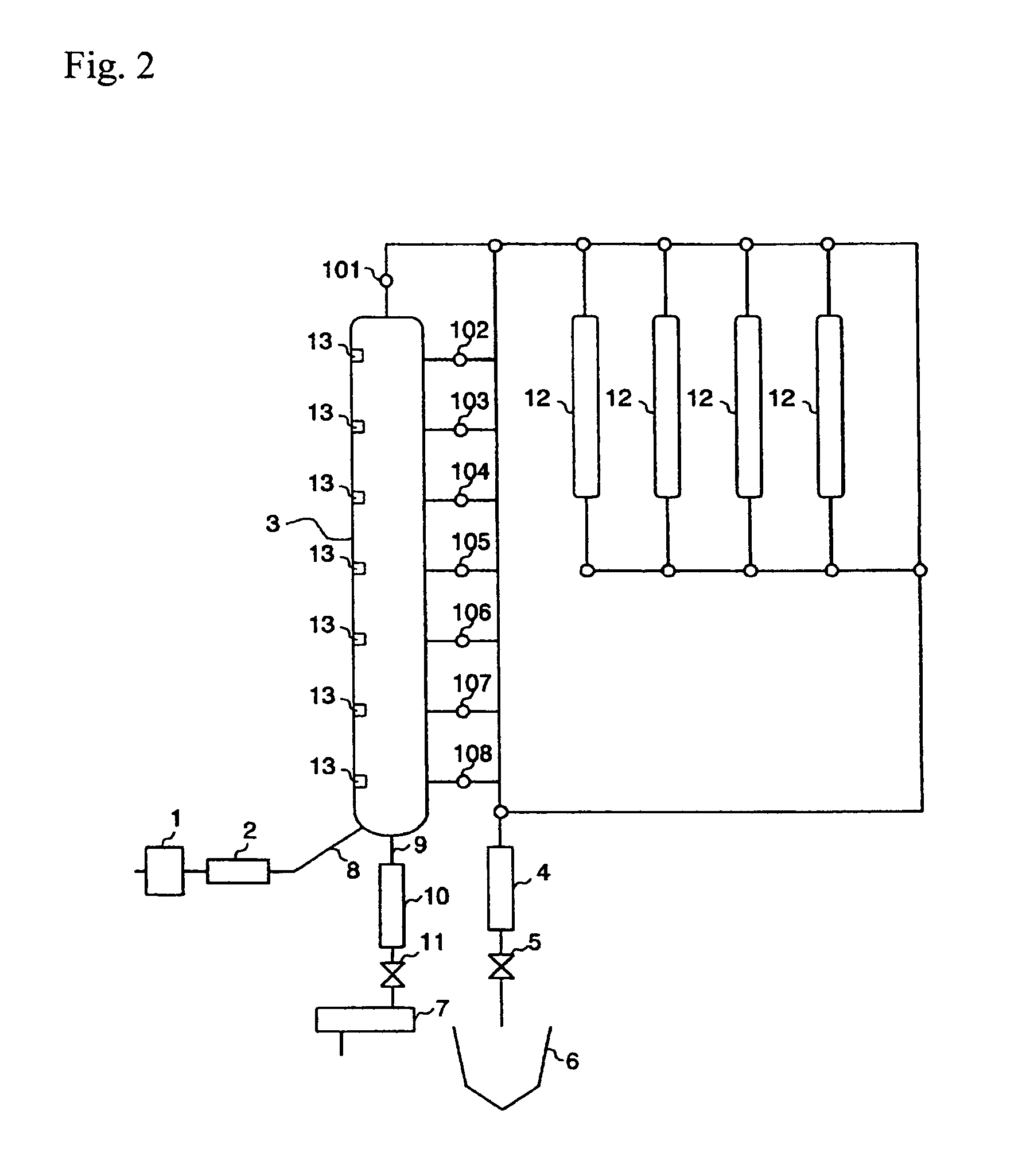

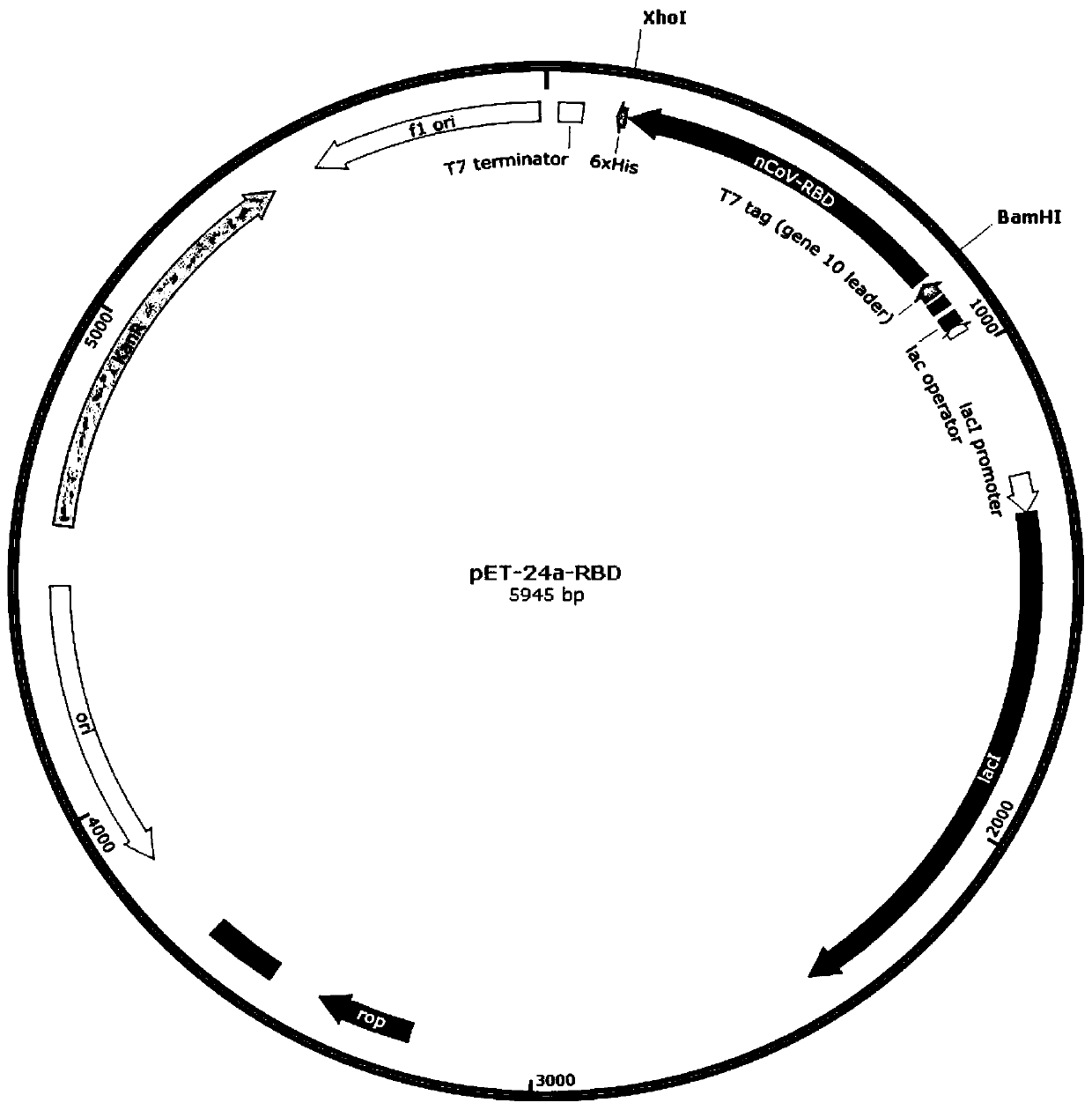

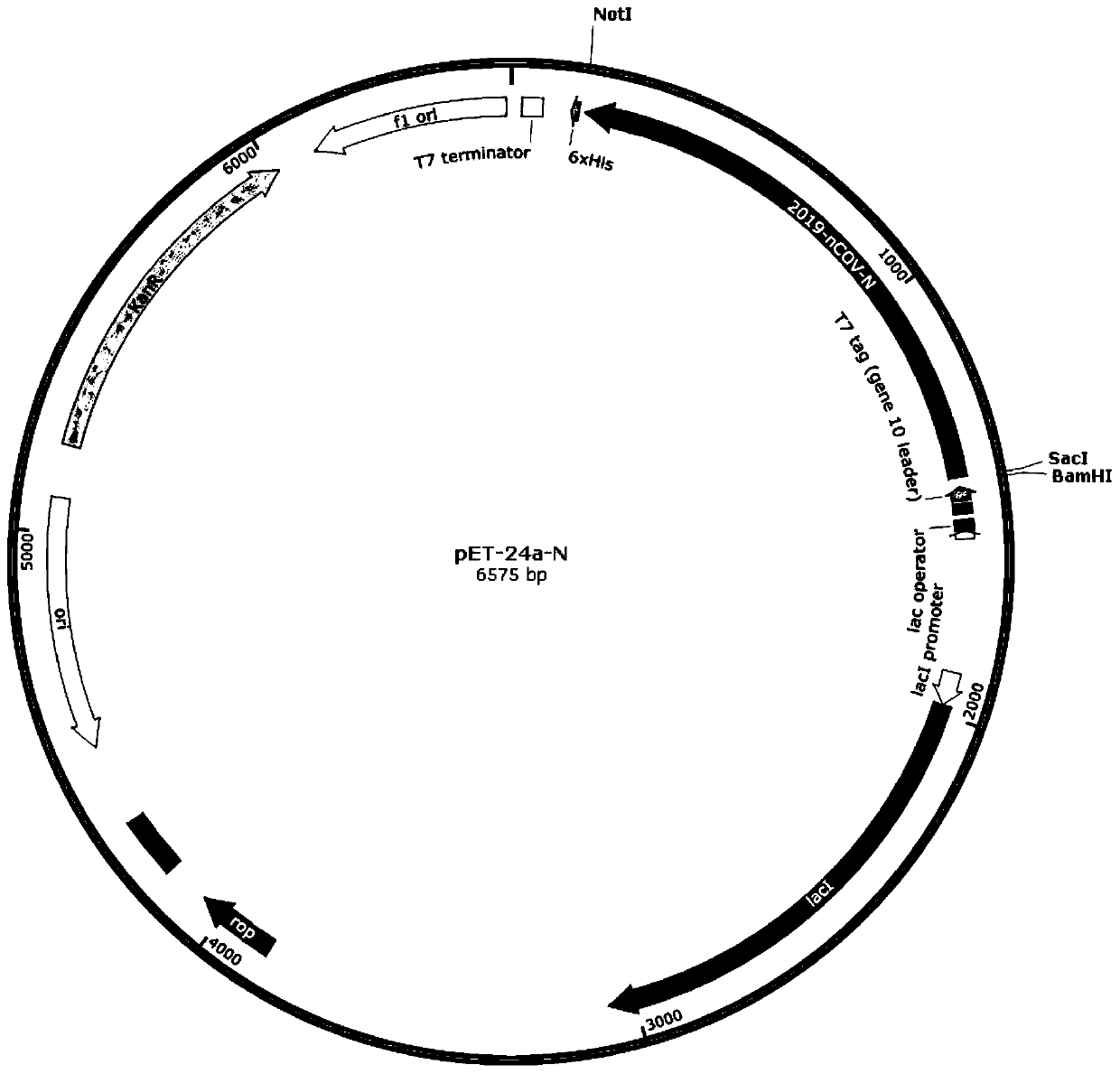

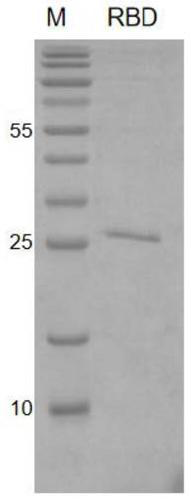

Renaturation method of COVID-19 recombinant protein inclusion bodies

InactiveCN111423486AShorten the timeQuality improvementSsRNA viruses positive-senseVirus peptidesInclusion bodiesBiochemistry

The invention discloses a renaturation method of COVID-19 recombinant protein inclusion bodies. According to the renaturation method of the COVID-19 recombinant protein inclusion bodies provided by the invention, after a denatured inclusion body dissolution product is treated by using a nickel chelating column, a renaturation solution containing a denaturant and a reduced concentration gradient ofthe denaturant is used for gradient elution at normal temperature for flow renaturation, so that the method not only reduces the costs, but also significantly shortens the time required for the renaturation of the COVID-19 recombinant protein inclusion bodies, thereby facilitating large-scale renaturation of the COVID-19 recombinant protein inclusion bodies in a short time and at a lower cost; and the protein recovery is high, the purity is high, and the stability is strong, so that a large number of high-quality COVID-19 proteins can be conveniently obtained in a short time and at a lower cost for COVID-19 detection and antibody preparation. The renaturation method of the COVID-19 recombinant protein inclusion bodies provided by the invention is suitable for the renaturation of the COVID-19 RBD recombinant protein inclusion body or the COVID-19 N recombinant protein inclusion body.

Owner:艾柏森(江苏)生物科技有限公司

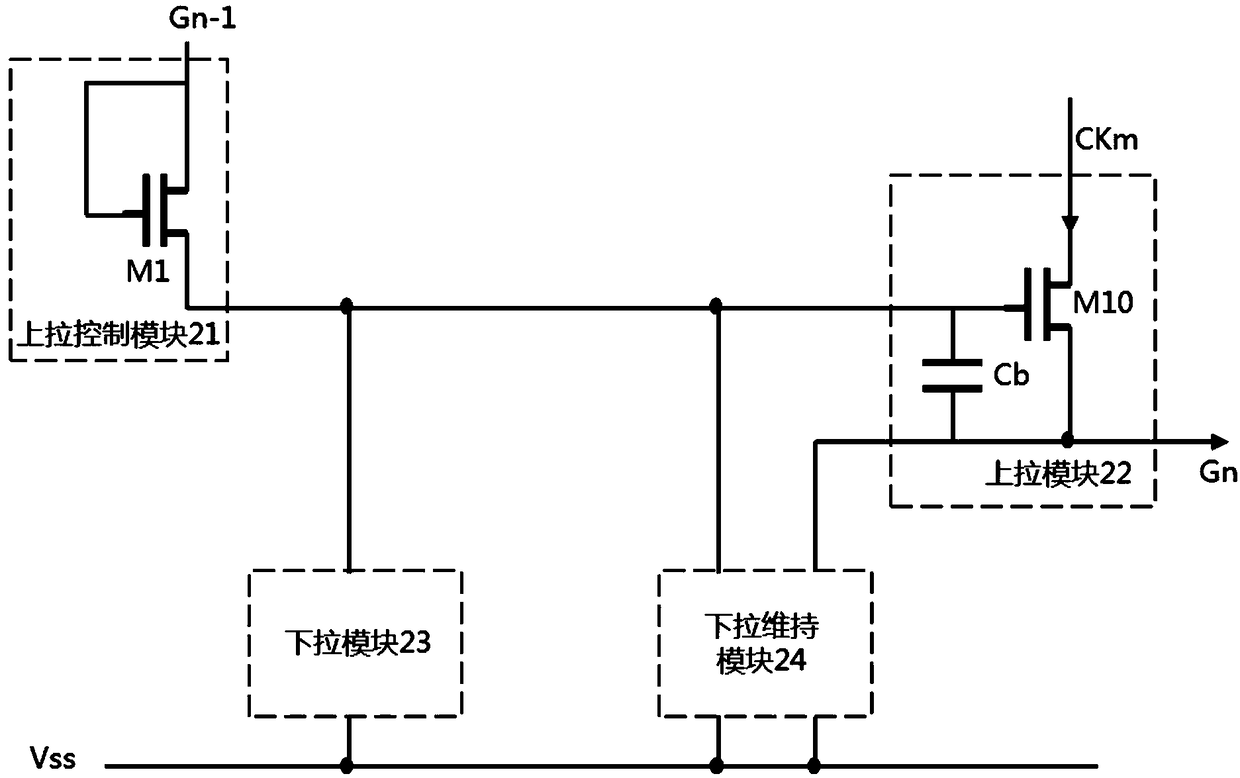

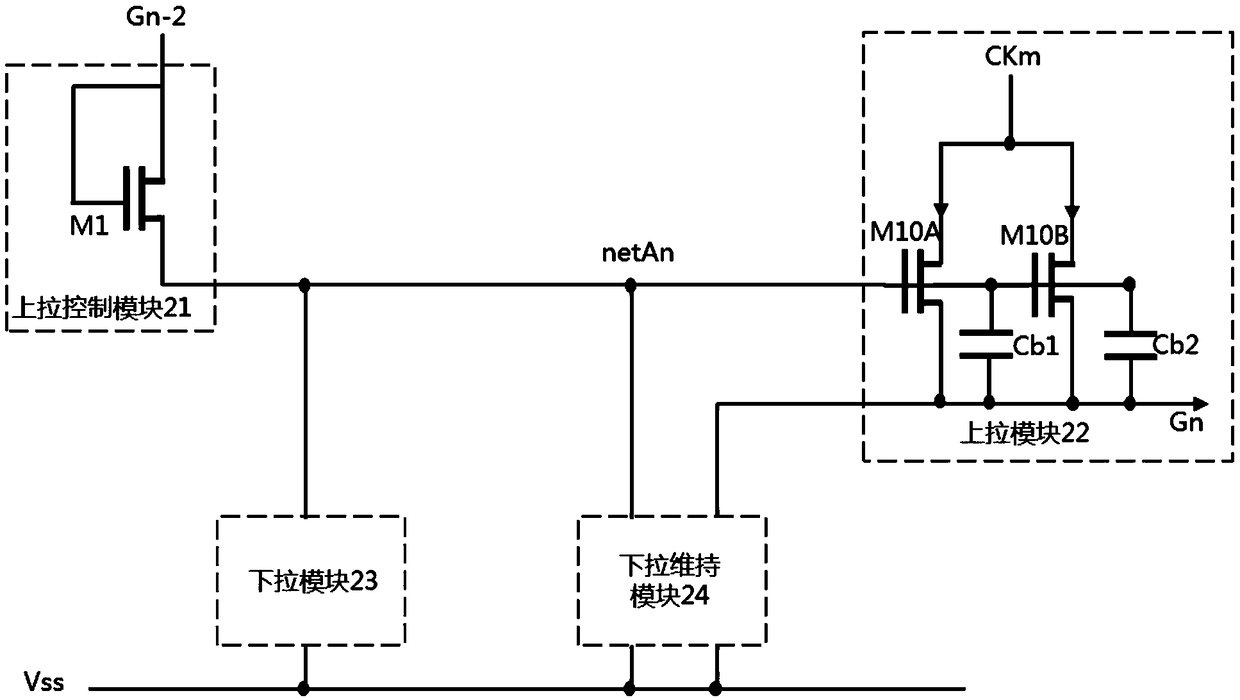

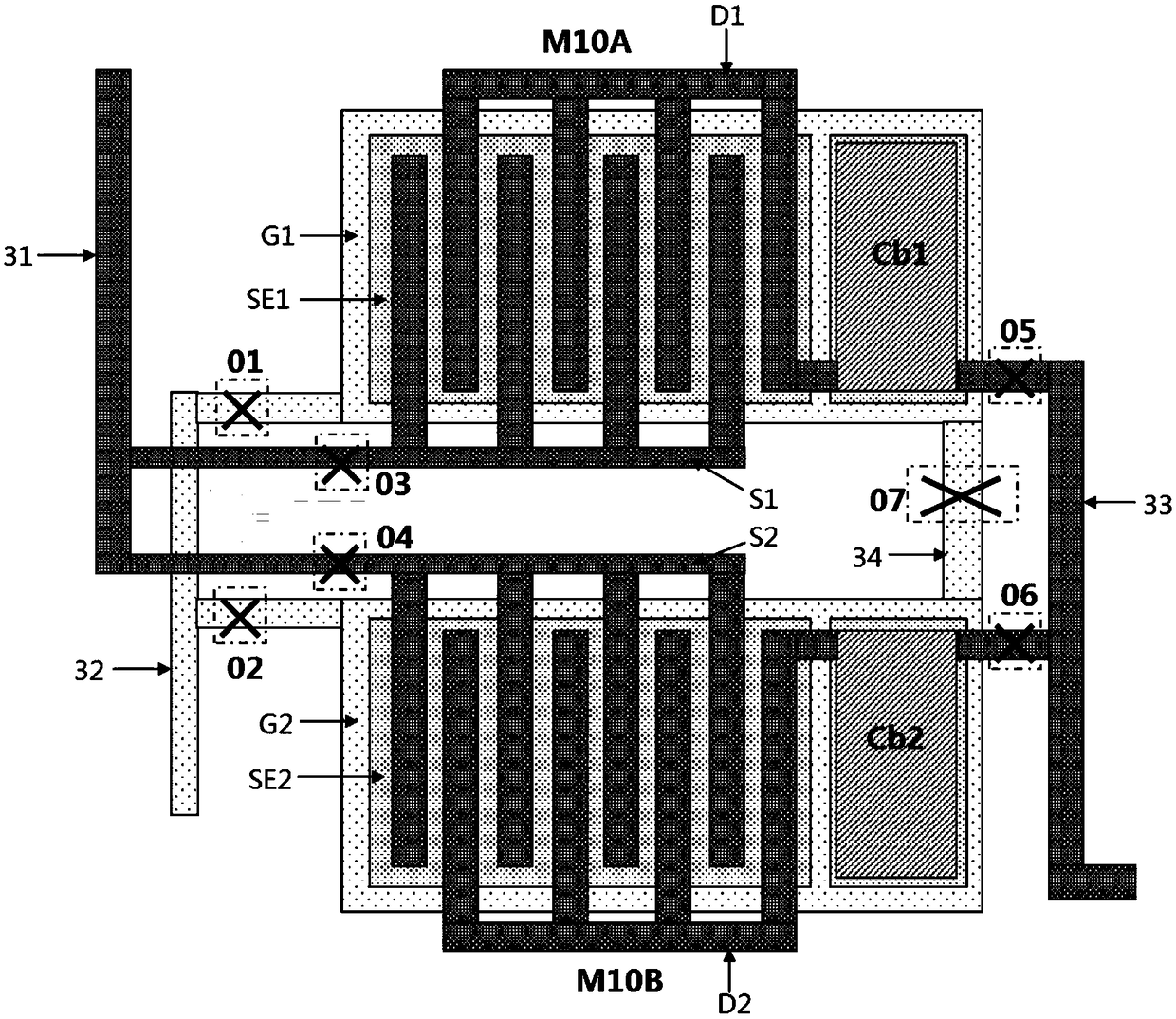

Gate driver monolithic and repairing method thereof

InactiveCN108766334AReduce areaReduced chance of injury or damageStatic indicating devicesGate driverLaser cutting

The invention discloses a gate driver monolithic and a repairing method thereof. According to the gate driver monolithic, certain thin film transistors having important functions or excessive channelwidths in an existing circuit structure are replaced with two or more independent units, and laser cutting or connecting spaces are reserved on a layout for the gates, the sources, and the drains of respective independent units. When one or more independent units are damaged or broken, the damaged or broken units are cut and isolated and the unharmed units continue working, thereby achieving repairability at a thin film transistor level. While the repairability is achieved, the thin film transistors with small area can reduce a damaging or breaking probability in the process flow. It is not required to dispose additional candidate shift registers and repair lines in the gate driver monolithic area. A repair process generally requires only laser cutting and connecting operations such that the repairing method is simple and is suitable for large-scale operations.

Owner:NANJING CEC PANDA LCD TECH

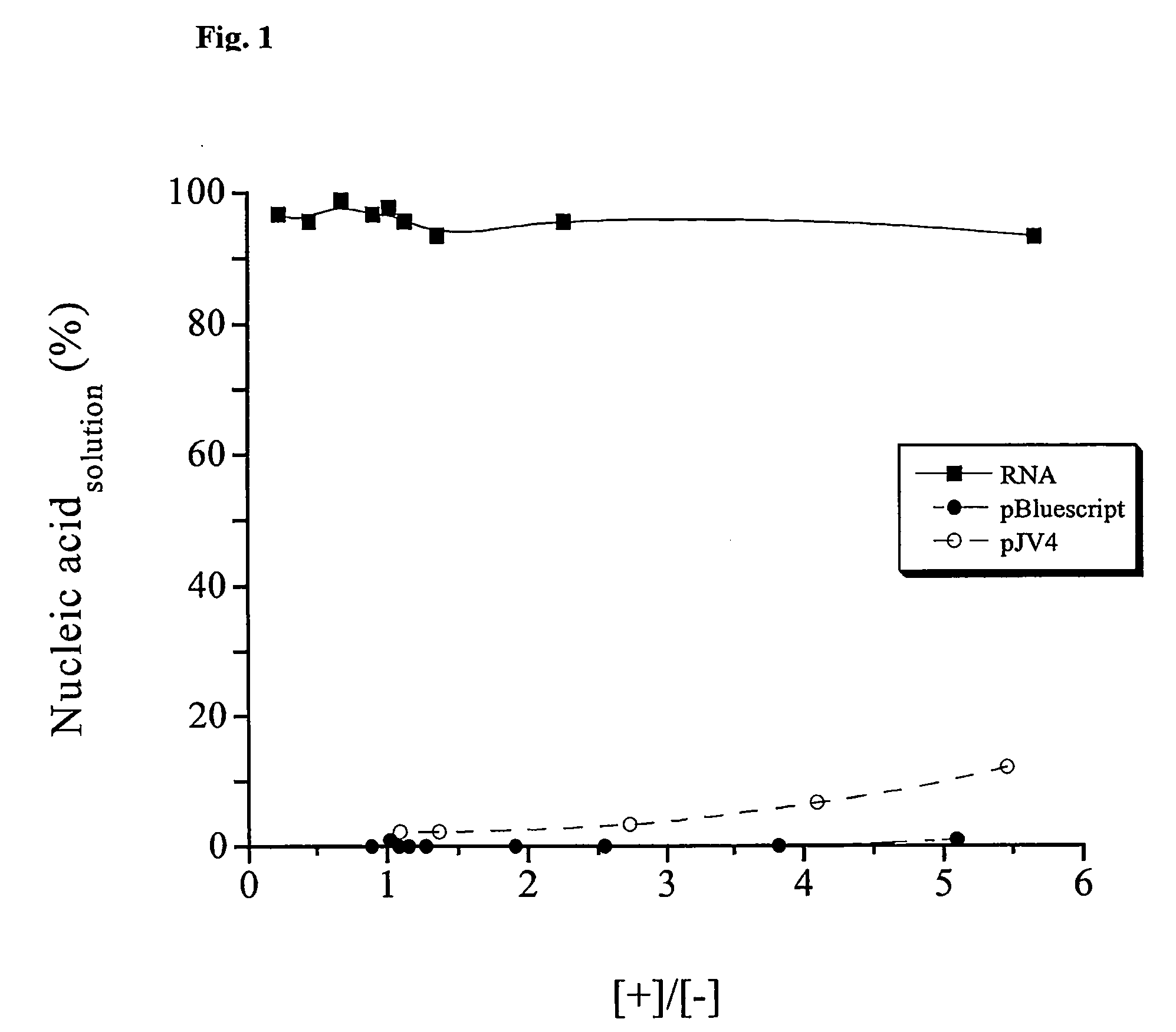

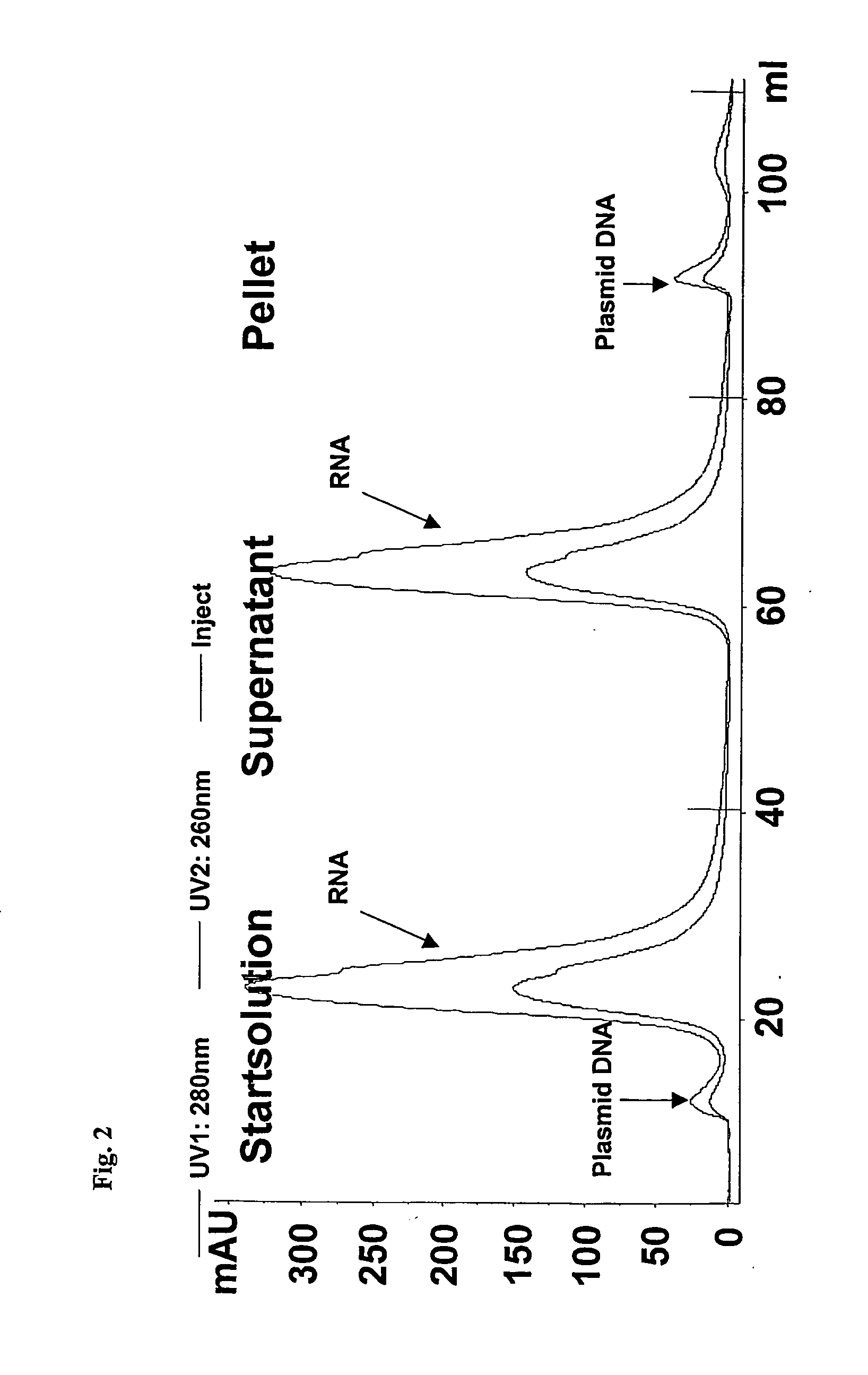

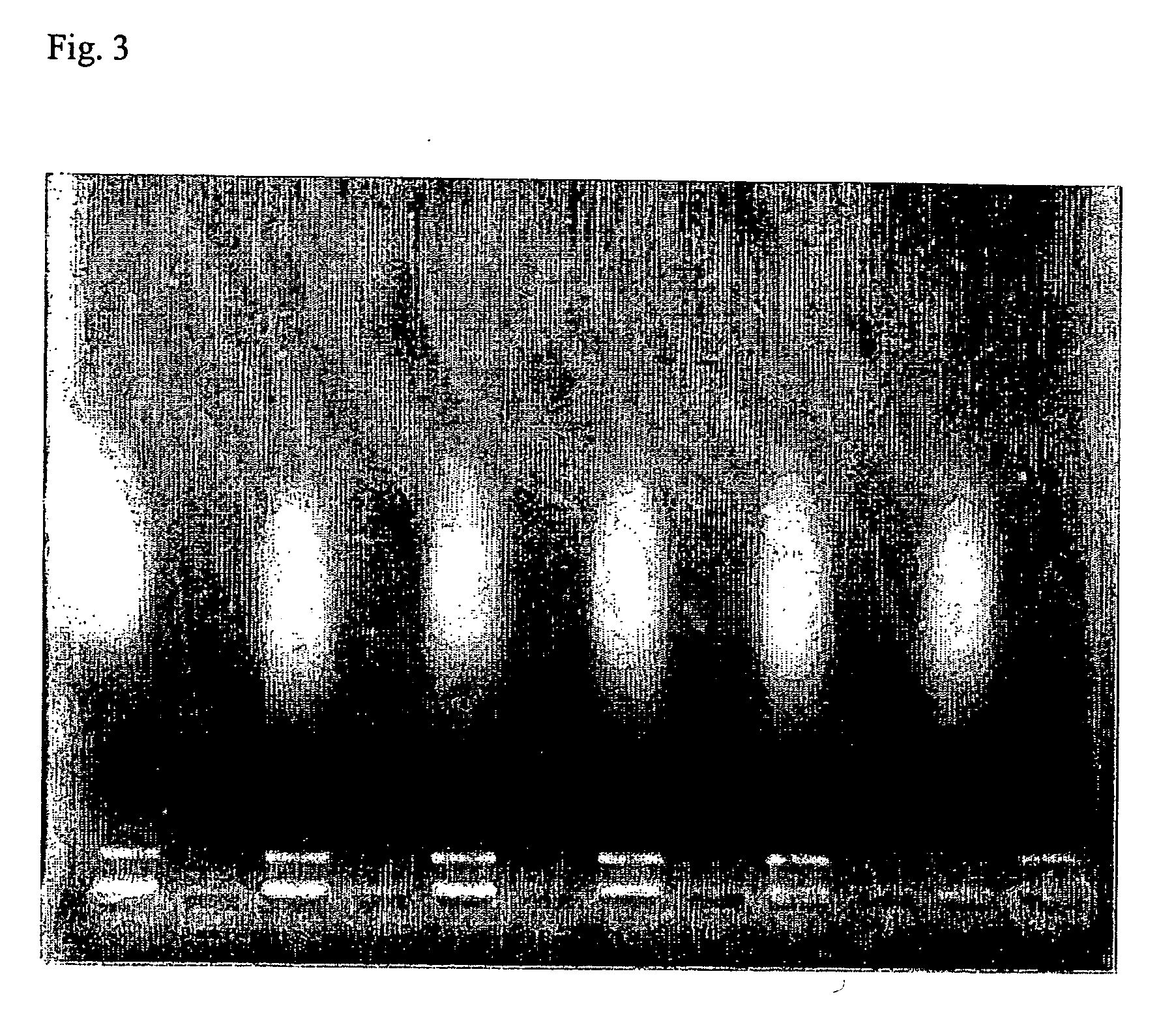

Isolation of nucleic acids using a polycationic polymer as precipitation agent

InactiveUS20050222404A1Suitable for large-scale operationCost-effectiveSugar derivativesSugar derivatives preparationLinear polymerNucleic acid

The present invention relates to a method of isolating a desired nucleic acid from a biological solution, which method comprises to selectively precipitate the desired nucleic acid by adding a polycationic precipitating agent to the solution and allowing it to form a complex with said nucleic acid, wherein the precipitating agent is a highly charged linear polymer that comprises quaternary amino groups. The polycationic precipitating agent is preferably added in such an amount that the charge ratio [+] / [−] between polycationic precipitating agent and nucleic acid is ≧0.5, preferably ≧0.9 and most preferably ≧1 during the precipitation, and in the presence of a salt concentration ensuring the quantitative specific precipitation of the nucleic acid / polycation complex.

Owner:GE HEALTHCARE BIO SCI CORP

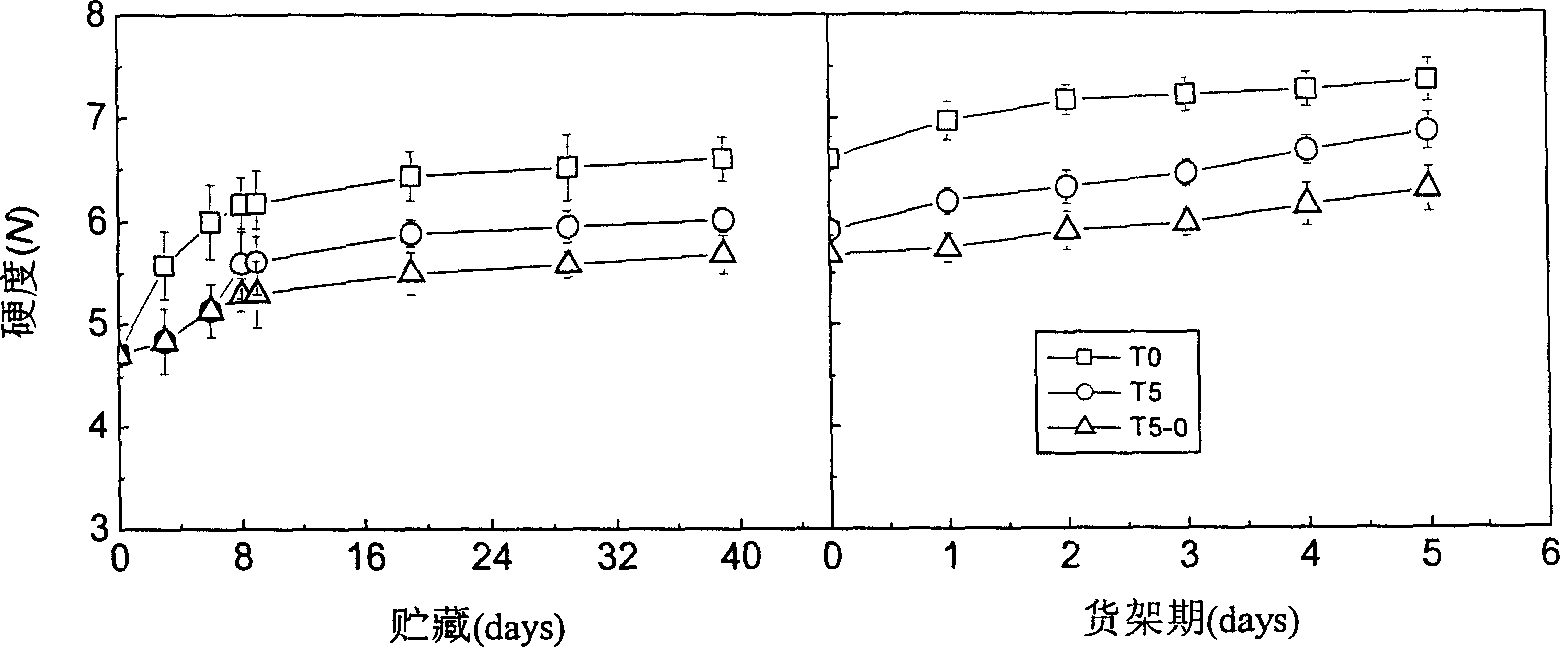

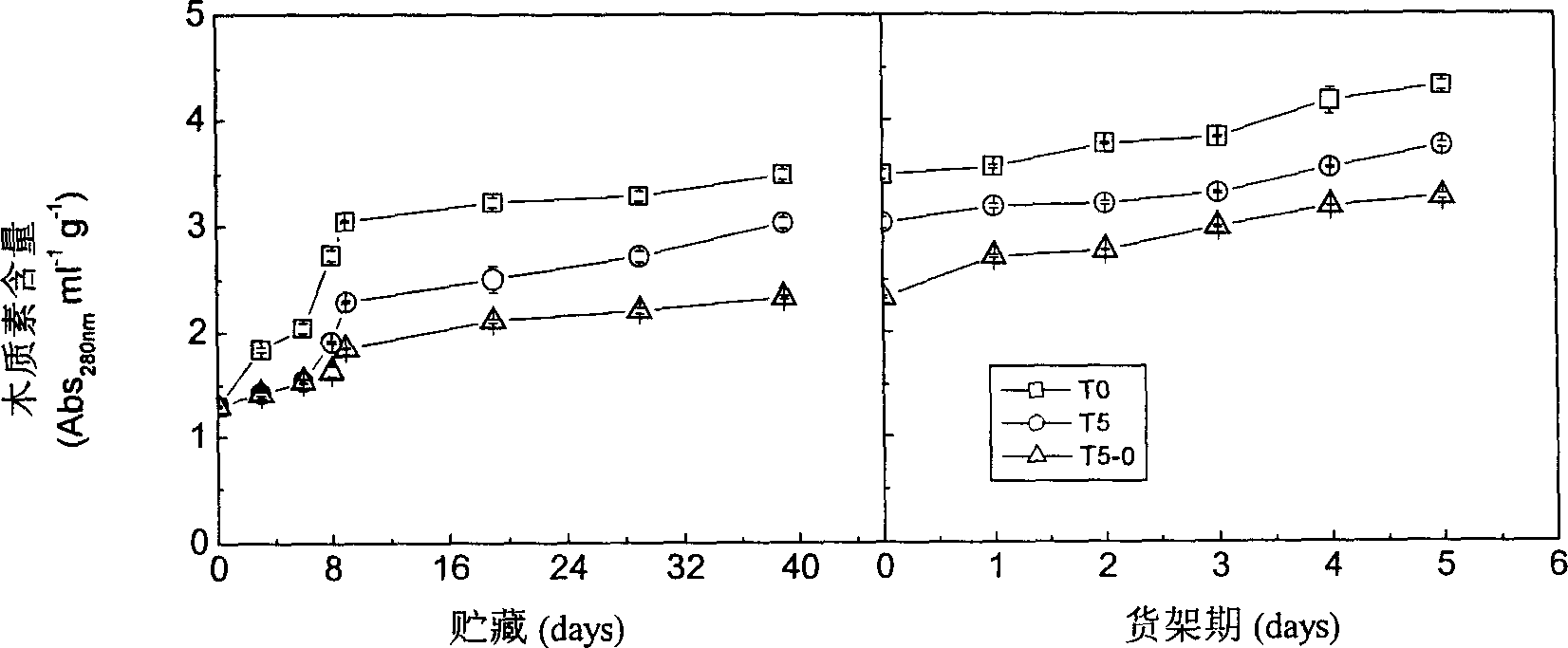

Method for storing loquat fruit in low-temperature

InactiveCN1644064AReduce chilling damageImprove qualityFruits/vegetable preservation by freezing/coolingBiology

Owner:ZHEJIANG UNIV

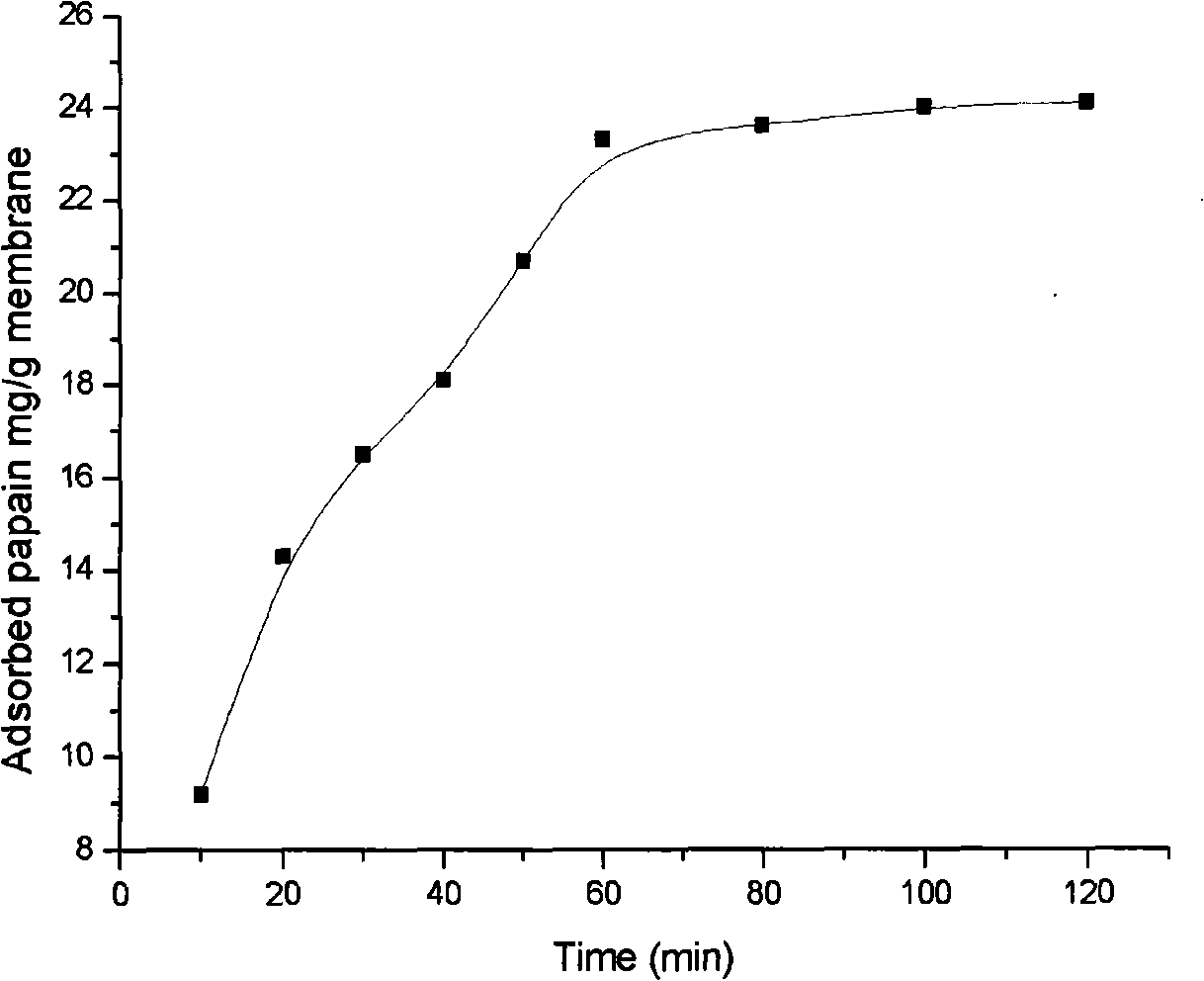

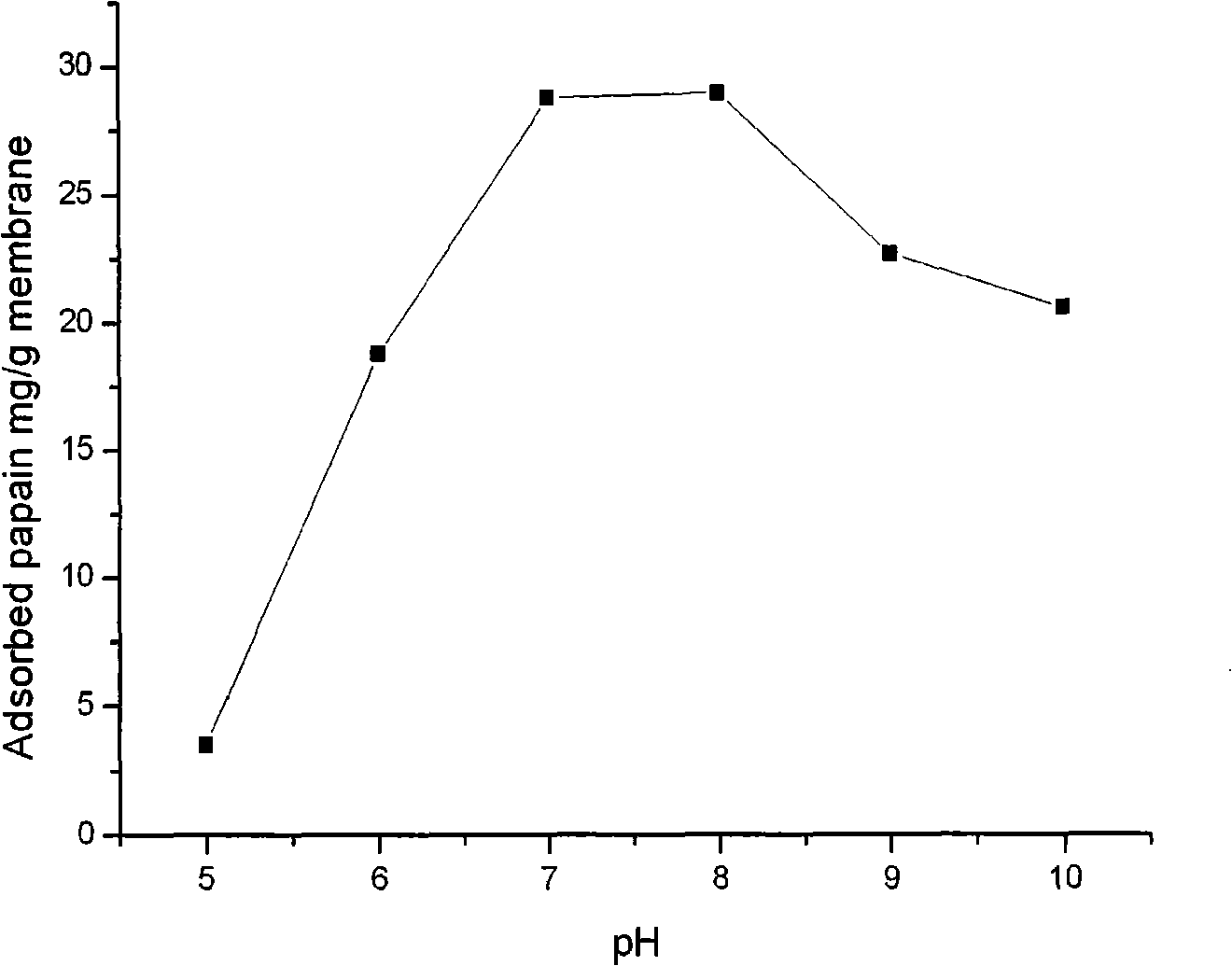

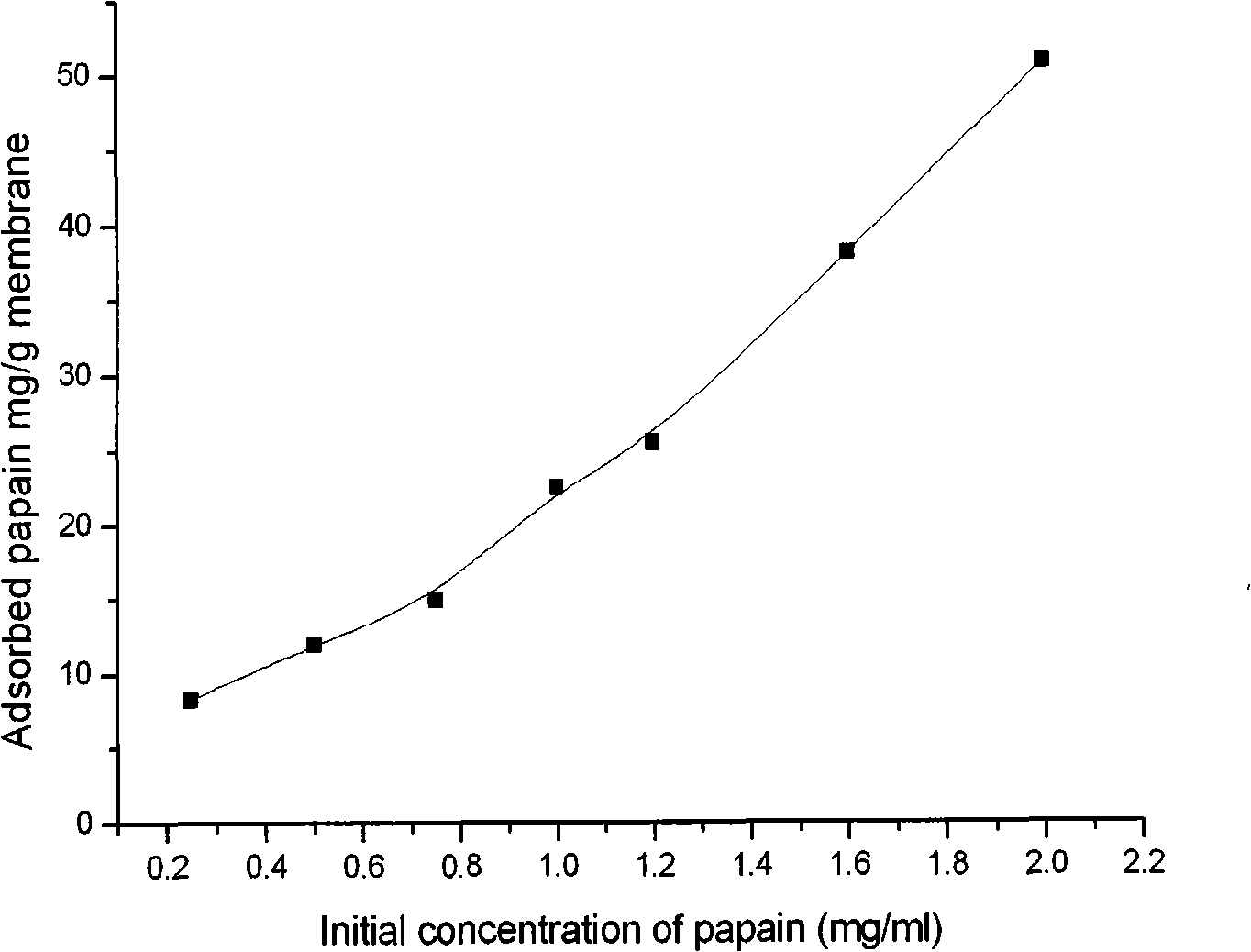

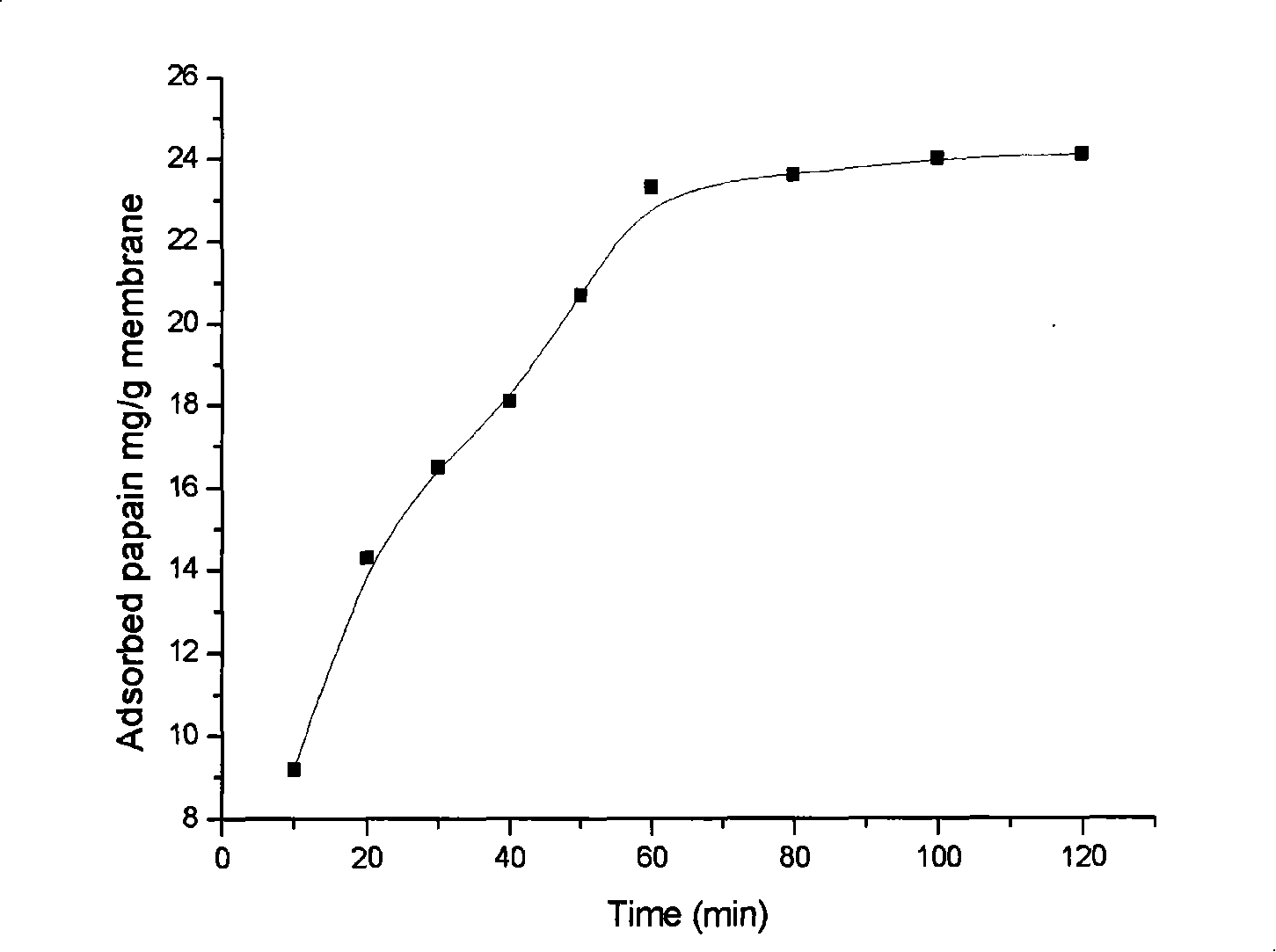

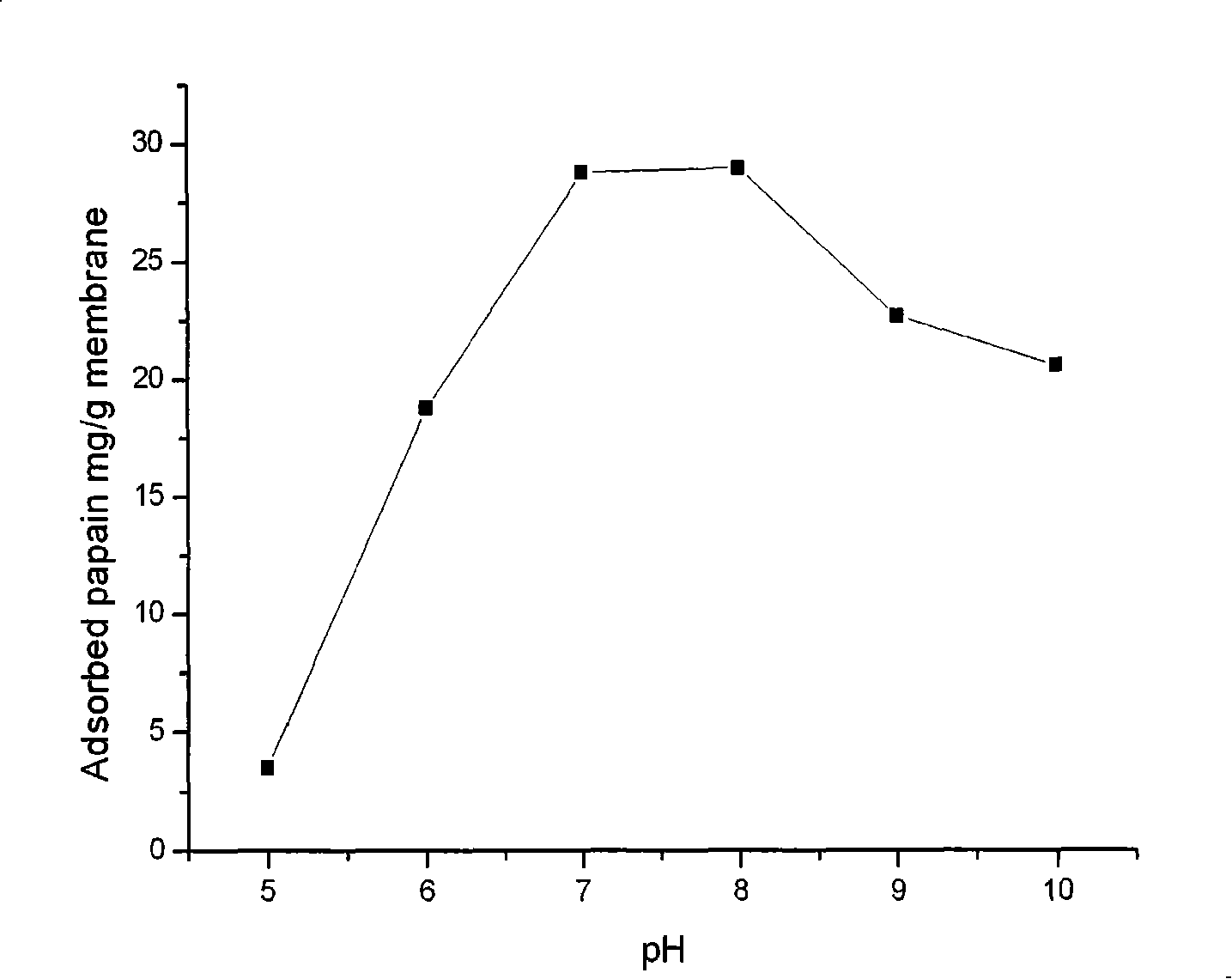

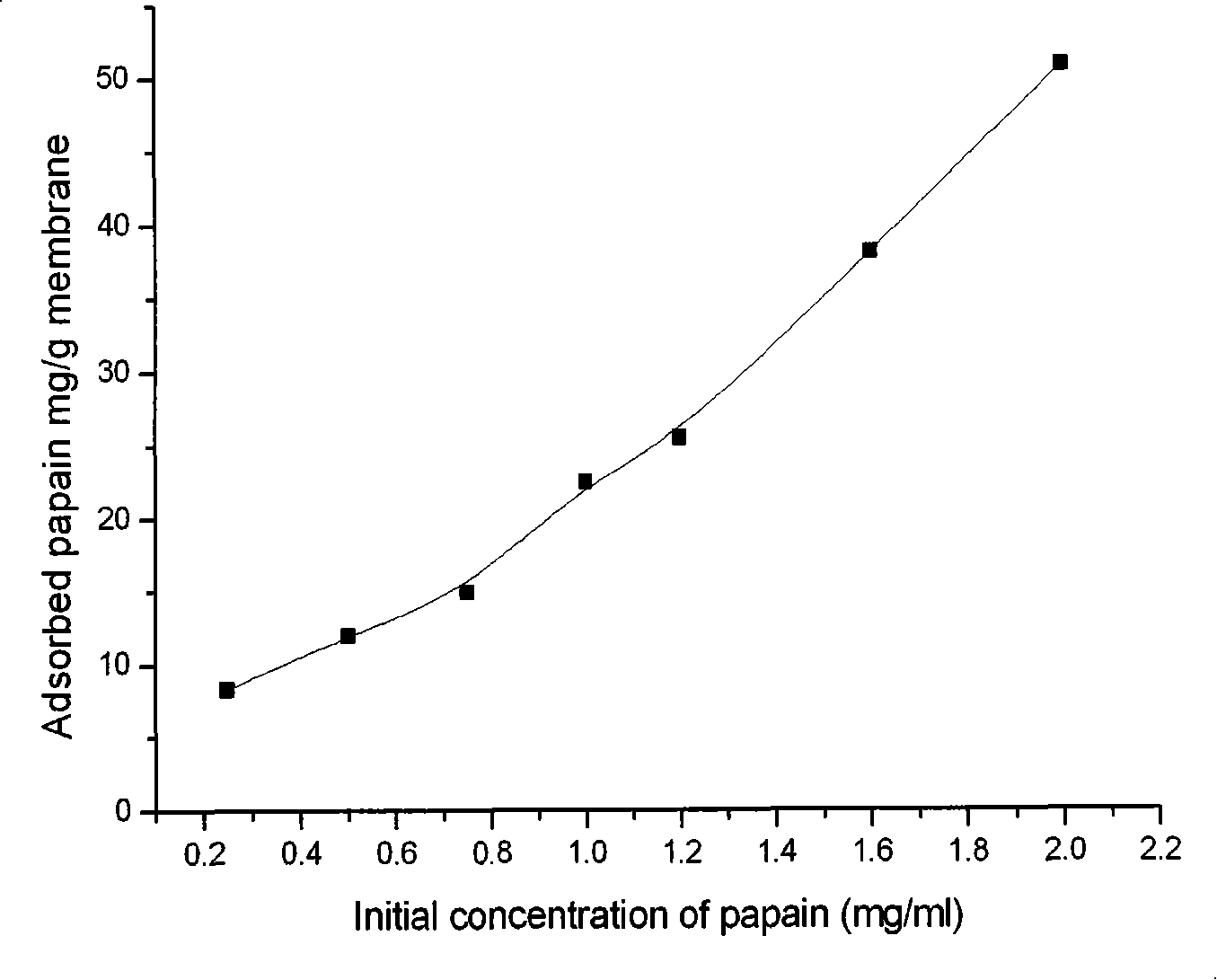

Method for purifying velardon by using metallic affinity membrane

InactiveCN101270351ASuitable for large-scale operationWide variety of sourcesHydrolasesPeristaltic pumpSodium hydroxide

The invention relates to a method for purifying papain with a metal affinity membrane, which comprises the steps that (1) a nylon membrane is activated with formaldehyde and modified with chitosan; (2) the activated and modified nylon membrane reacts with the mixture solution of epichlorohydrin, sodium hydroxide and sodium borohydride; and the membrane is submersed in the mixture solution of sodium carbonate, sodium borohydride and an coupling agent, and in copper sulphate solution, respectively to get the chelating copper ion metal affinity membrane; (3) the metal affinity membrane is folded up to become a membrane pile, and the membrane pile is arranged in a membrane bridge before the membrane pile is fed into Tris-HCl buffer solution and eluent with a peristaltic pump; subsequently, the membrane pile is fed into papain solution, and is eluted with the eluent, thus getting the target product, namely papain; (4) the enzyme activity and the protein content are tested, and purification factor is calculated. The method is quick, simple and convenient, and can be used for separating papain in large quantity, and is applicable for large-scale production. In addition, the activity of the extracted enzyme is excellent.

Owner:DONGHUA UNIV

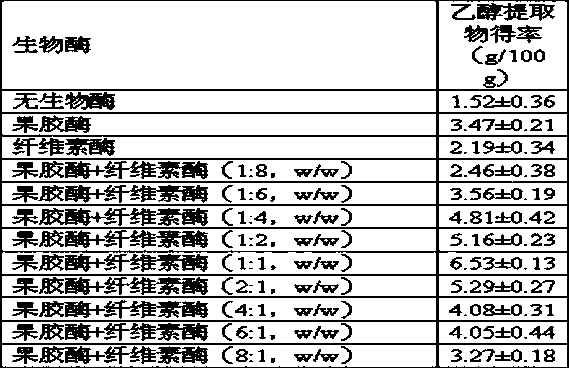

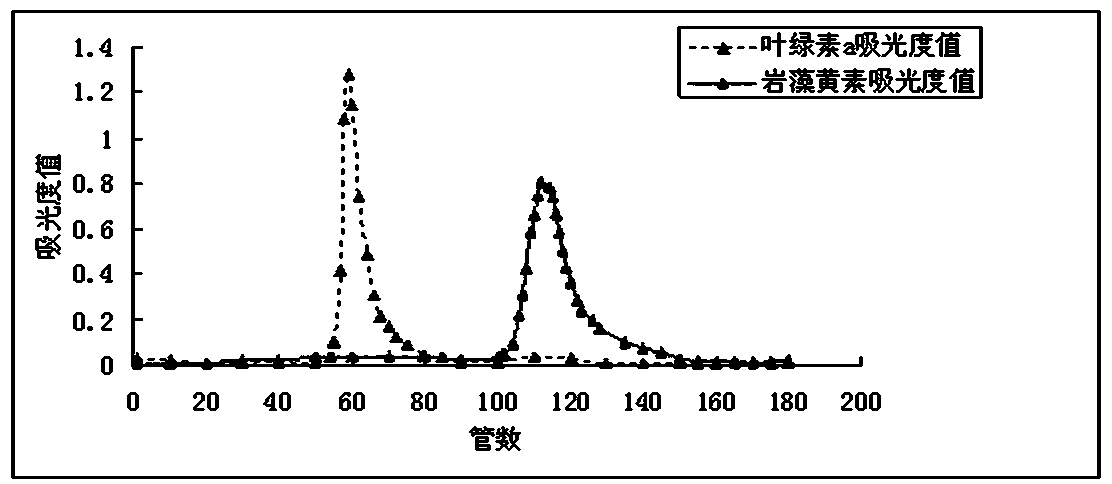

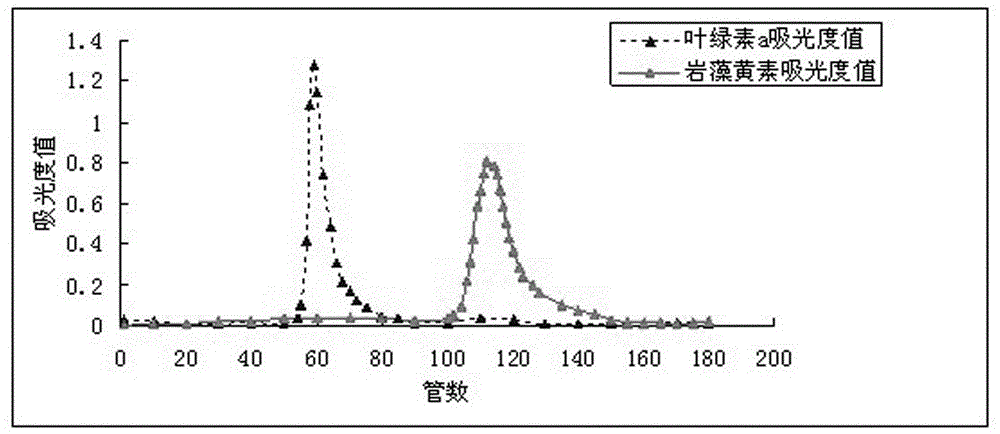

Preparation method and application of alga xanthophyll

InactiveCN104003962AImprove securityIncrease nutritionOrganic chemistryFatty substance preservation using additivesPectinaseFreeze-drying

The invention discloses a preparation method and application of alga xanthophyll. Kelp residue wall breaking is performed by biological enzymolysis to obtain wall-broken kelp residue dry powder, a used compound enzyme preparation is a mixture of pectinase and cellulose with the ratio of W / W= 1:1, the wall-broken kelp residue dry powder is extracted by an alkaline organic solvent, a supernatant and a kelp precipitate are respectively collected; the supernatant pH value is adjusted to neutral, the supernatant is centrifuged, a supernatant is removed, and an alga xanthophylls crude extract product is obtained by 12h of vacuum freeze drying of the precipitate; then an organic solvent and silica gel chromatography column are used for purification, and the alga xanthophylls can be obtained by vacuum concentration and vacuum drying. The alga xanthophylls prepared by the preparation method has a yield reaching up to 2.5 wt%, and the preparation method has the advantages of simple operation, environmental protection and high efficiency, and is suitable for large scale production.

Owner:JIMEI UNIV

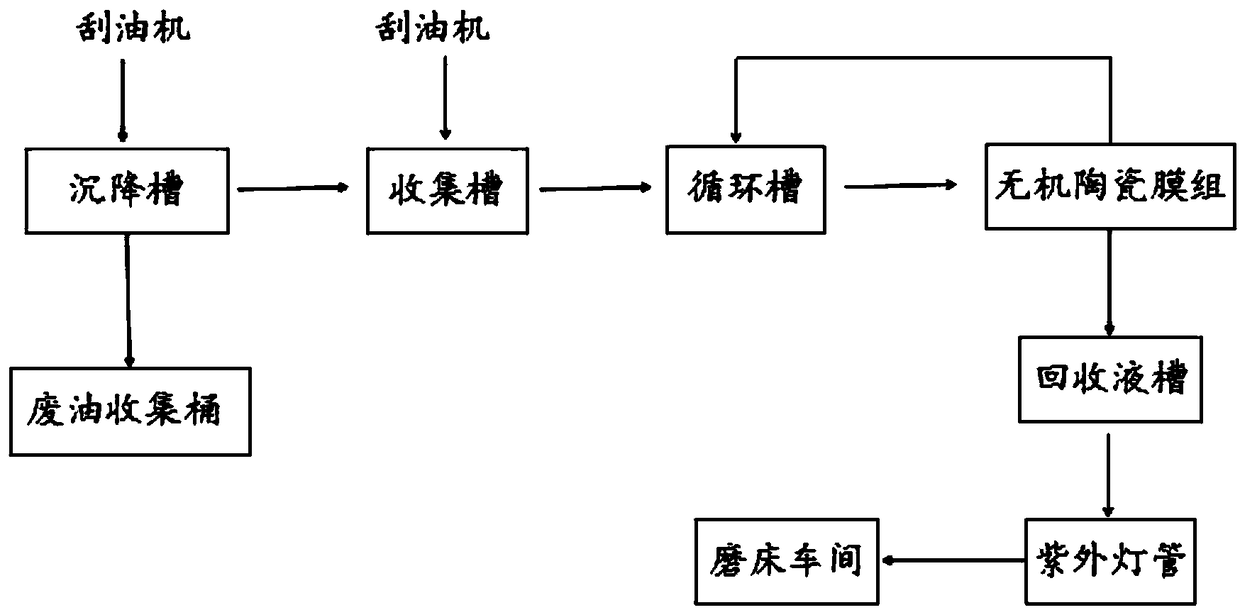

Method for recovering cutting fluid by ceramic membrane filtration

InactiveCN108083525AAchieve purification effectAchieve recyclingFatty/oily/floating substances removal devicesWater/sewage treatment by irradiationPreservativeLiquid tank

The invention discloses a method for recovering cutting fluid by ceramic membrane filtration. The method comprises the following steps: (1) preliminary oil removal treatment is performed; (2) secondary oil removal treatment is performed; (3) the cutting fluid flows through an inorganic ceramic membrane group and is filtered and purified; (4) the cutting fluid filtered by the inorganic ceramic membrane group enters a recovery liquid tank, flows through an ultraviolet lamp tube for sterilization and then is supplied to a grinding machine workshop. The cutting fluid is filtered and recovered withan inorganic ceramic membrane technology and can be purified and recovered, pollutant oil, bacteria and impurities in the cutting fluid are removed, and main raw materials such as a surfactant, a preservative, a bactericide and the like of the cutting fluid are retained, so that the cutting fluid is effectively recycled, and the recovery efficiency is high; The method is simple and easy to operate and is suitable for large-scale operation; the recovered cutting fluid is sterilized by the ultraviolet lamp tube, bacterial contamination in the cutting fluid can be removed, and the cutting fluidis purified.

Owner:安徽名创新材料科技有限公司

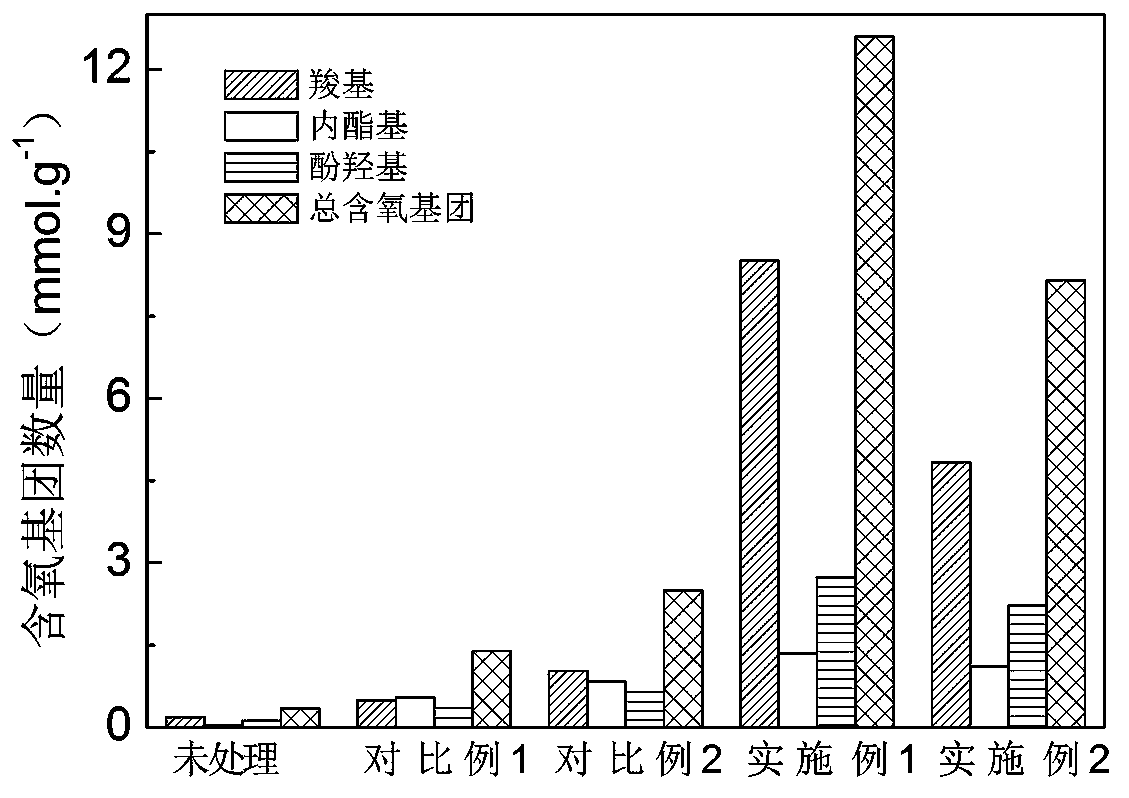

Technology for synergistically increasing oxygen-containing groups in charcoal with ozone and ultraviolet irradiation

PendingCN109926023AWill not polluteReduce processing costsOther chemical processesTemperature controlUltraviolet

The invention relates to a technology for synergistically increasing oxygen-containing groups in a charcoal material with ozone and ultraviolet irradiation. The technology mainly comprises the following steps: the prepared charcoal material is sieved, washed and dried, then is mixed with ozone, and is heated to 100-500 DEG C; the charcoal material is spread on a temperature-controlled electric hotplate, and is irradiated with an ultraviolet irradiation lamp having an ultraviolet ray wavelength of 10-380 nm for 24 h, the material is placed in an ozone contact column one time every 12 h, and ozone is introduced, wherein the temperature of the charcoal is kept at 200 DEG C in the irradiation process; and the charcoal material is dried after the ultraviolet irradiation is finished. The technology can significantly increase the quantity of the oxygen-containing groups in the charcoal material.

Owner:ANHUI SCI & TECH UNIV

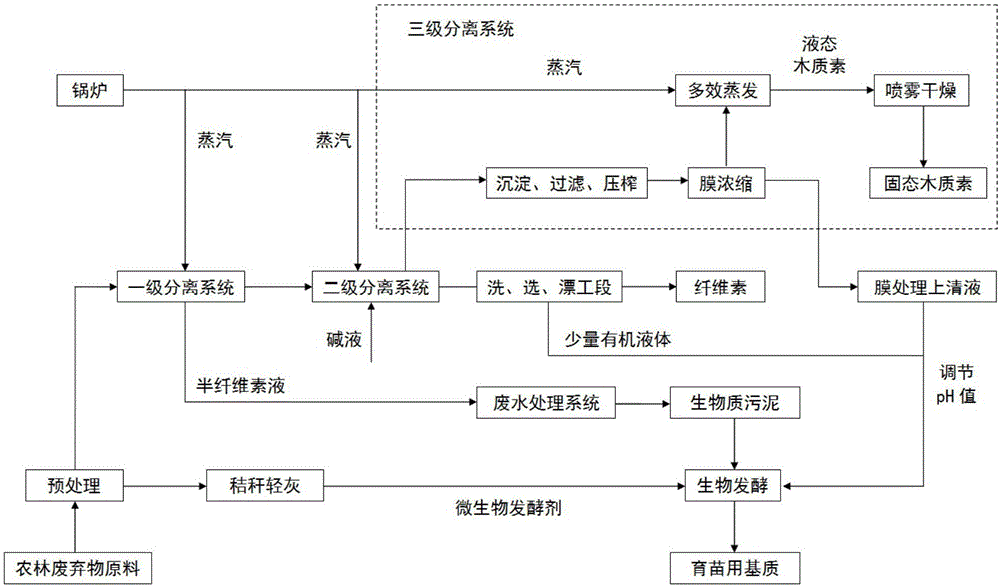

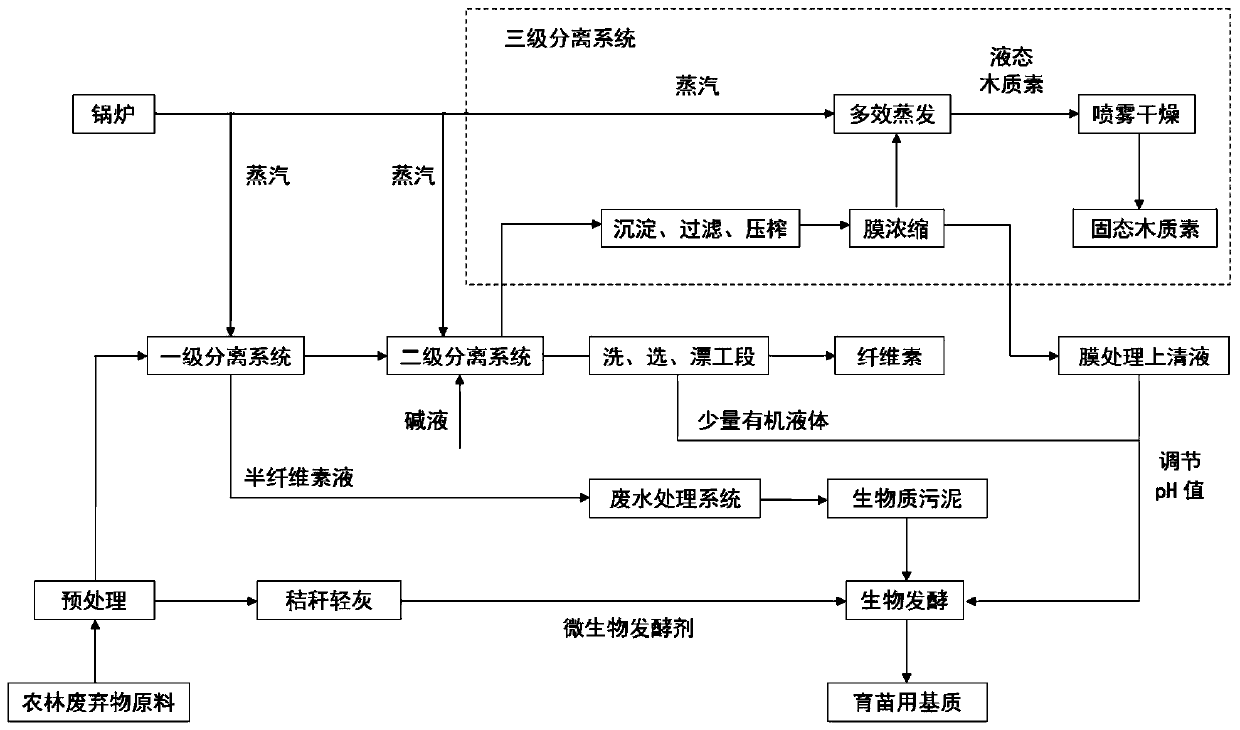

Matrix for culturing seedlings and preparing method thereof

The invention belongs to the technical field of matrix preparing, and particularly relates to a matrix for culturing seedlings and a preparing method thereof. The matrix for culturing seedlings is prepared from biomass sludge, straw light ash, organic wastewater and a microorganism fermenting agent. The matrix for culturing seedlings is economical, efficient and good in safety, healthy seedling cultivating is facilitated, the matrix is not influenced by the weather, and application prospects are good.

Owner:ANHUI GEYI CYCLIC ECONOMY IND PARK

Method for extracting blue pigment from purple cabbage

The invention discloses a method for extracting a blue pigment from purple cabbage. The method comprises steps as follows: digestion, microwave extraction and purification; purple cabbage pulp is digested through a digestion liquid and then centrifuged, microwave irradiation extraction is performed after a protectant is added to the liquid supernatant, and an ethanol solution of pigment colloid is purified through a silica gel chromatographic column. The method has the benefits as follows: the extraction method is simple and easy to control, consumes short time and is time-saving and labor-saving and suitable for large-scale operation, the process parameters such as temperature, pH values, solid-to-liquid ratio, extraction time, microwave power and the like in an extraction process are effectively controlled, the extraction process is optimized, and the influence of extraction conditions on the blue pigment is reduced to the minimum; a few metal ions in the system can change the color of the pigment and even can change the structure of the pigment, the protectant is added and can form a complex together with the metal ions in the system, and accordingly, the influence of the metal ions on the pigment is avoided. The method for extracting the blue pigment from purple cabbage is safe and efficient.

Owner:浦江县泰如食品科技有限公司

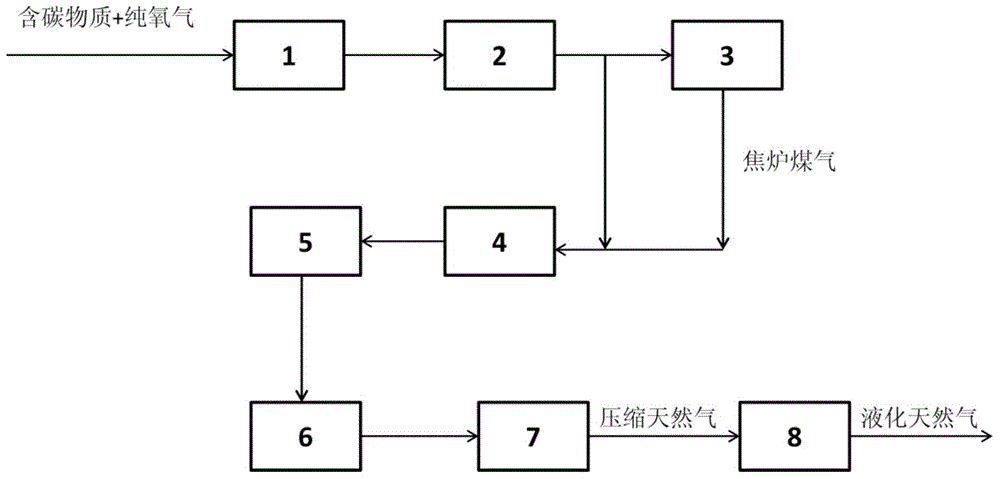

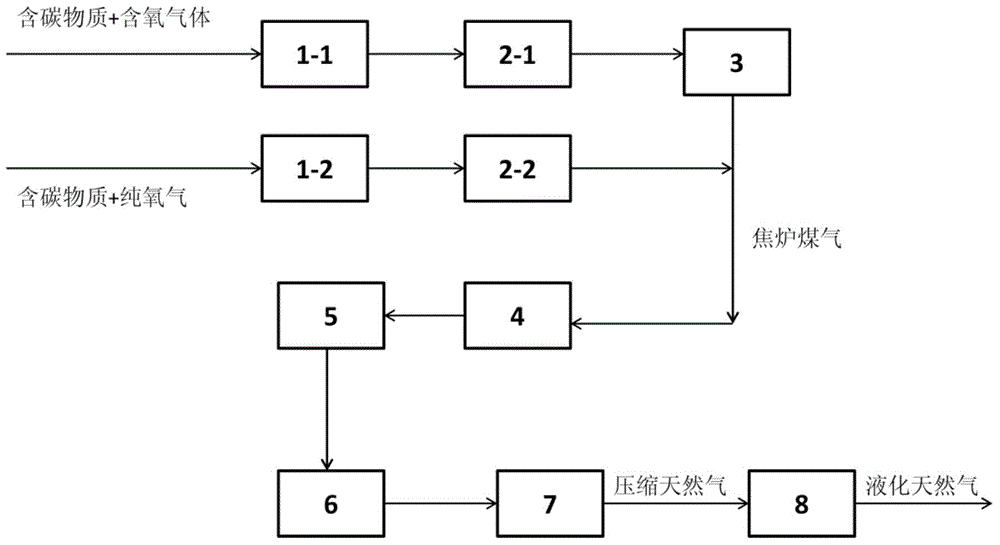

Water-saving type compressed natural gas production system and production method thereof

InactiveCN104152200ASolve the problem of not being able to supply more coke oven gasReduce consumptionGaseous fuelsGranular/pulverulent flues gasificationWater savingCompressed natural gas

The invention discloses a water-saving type compressed natural gas production system, which comprises a carbonaceous substance gasification unit 1, wherein the outlet of the carbonaceous substance gasification unit 1 is communicated to a purifying unit 2, the outlet pipeline of the purifying unit 2 is divided into two branch pipes, the first branch pipe is communicated to a combustion chamber of a coke oven unit 3, the second branch pipe and the coke oven gas outlet pipe of the coke oven unit 3 are combined and then communicated to a compression unit 4, and a fine desulfurization unit 5, a methanation unit 6 and a demercuration-drying unit 7 are arranged at downstream of the compression unit 4 in order. The invention also discloses a water-saving type compressed natural gas production method by using the above system. The system and method of the present invention can effectively use the carbonaceous substance generated in a coking process, superfluous hydrogen in coke oven gas can be fully used, coke oven gas consumption for producing per unit of liquefied natural gas can be greatly reduced through gas distribution, yield of liquefied natural gas can be increased by more than 30% under same consumption of coke oven gas, and the usage amount of water can be greatly reduced by the system.

Owner:BEIJING CHUANGSHI ENERGY TECH CO LTD

Straw puffed biological matrix material with sandwich type framework, and preparation method and application thereof

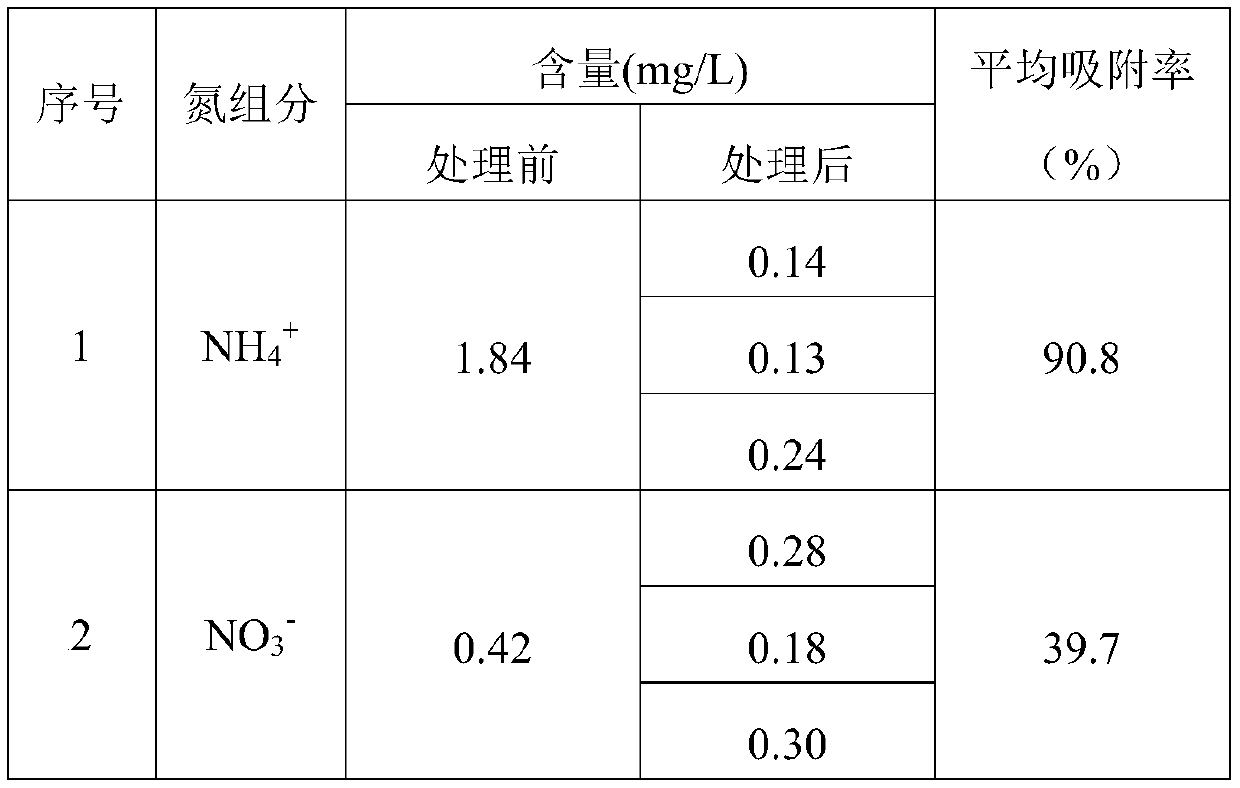

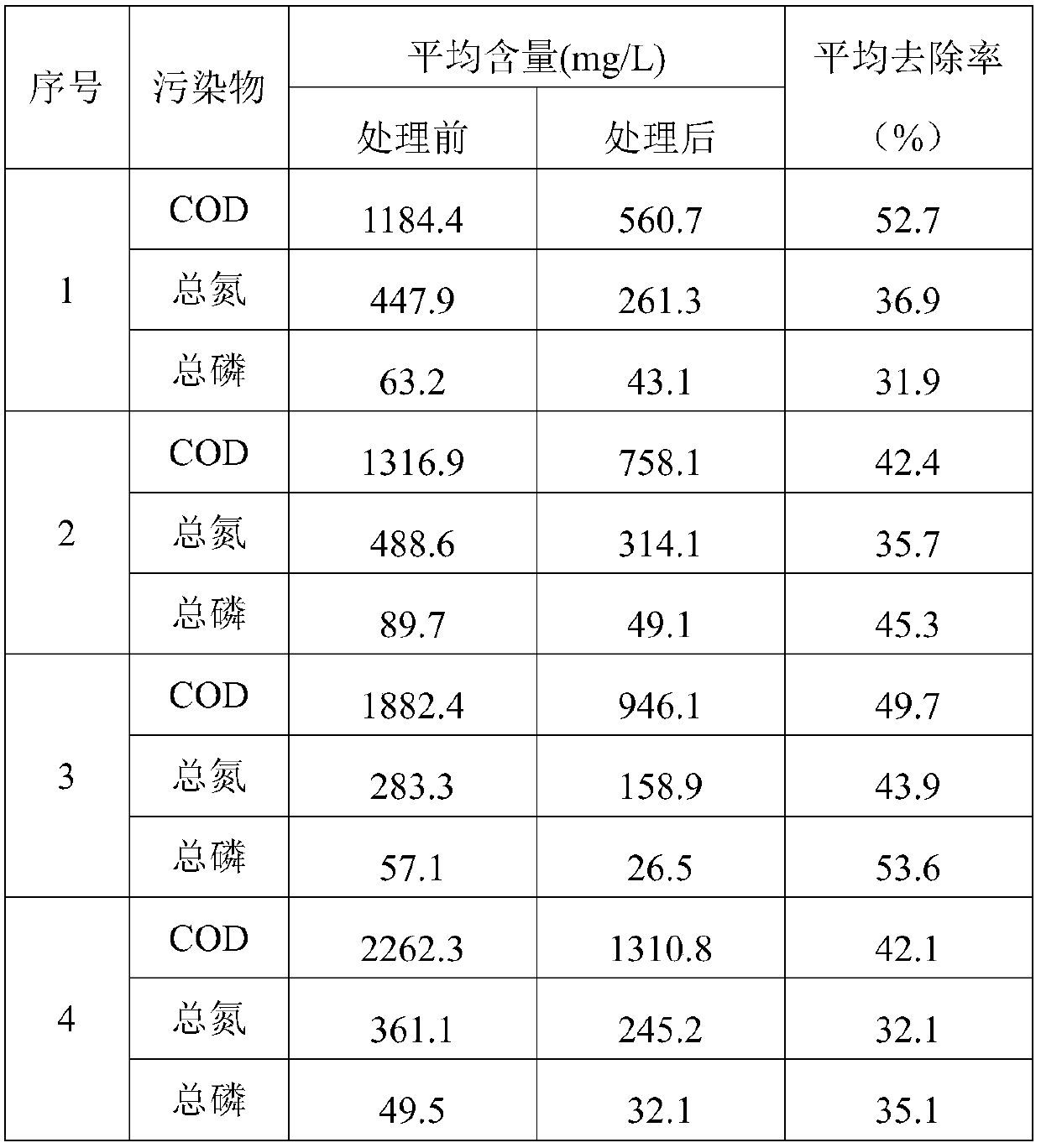

ActiveCN110813249AImprove stabilityHigh mechanical strengthOther chemical processesWater contaminantsAdhesiveSewage

The invention discloses a straw puffed biological matrix material with a sandwich type framework, and a preparation method and an application thereof. The straw puffed biological matrix material comprises matrix cushion layers and a matrix filler, wherein the matrix cushion layers comprise an upper matrix cushion layer, a middle matrix cushion layer and a lower matrix cushion layer; the matrix filler is filled between adjacent matrix cushion layers to form a pre-finished product with a sandwich structure; the matrix cushion layers and the matrix filler are prepared by compounding of rice strawand an adhesive; and the outer layer of the pre-finished product with the sandwich structure is subjected to enveloping treatment by using the matrix cushion layers to be integrally formed. Accordingto the invention, the sandwich type framework prepared from the straw puffed matrix material increases the porosity and specific surface area of a puffed biological matrix, has good adsorbability topollutants like COD, nitrogen and phosphorus in sewage, increases the stability and mechanical strength of a puffed biological matrix, solves problems like expansion and dispersed suspension of the puffed biological matrix in water, and is easy to be recovered. The straw puffed biological matrix material provided by the invention has the following advantages: the preparation method is simple; energy consumption is low; raw materials are simple and easily-available; a material obtained after sewage treatment can be utilized for the second time; and good application prospects are achieved.

Owner:HUAIYIN TEACHERS COLLEGE

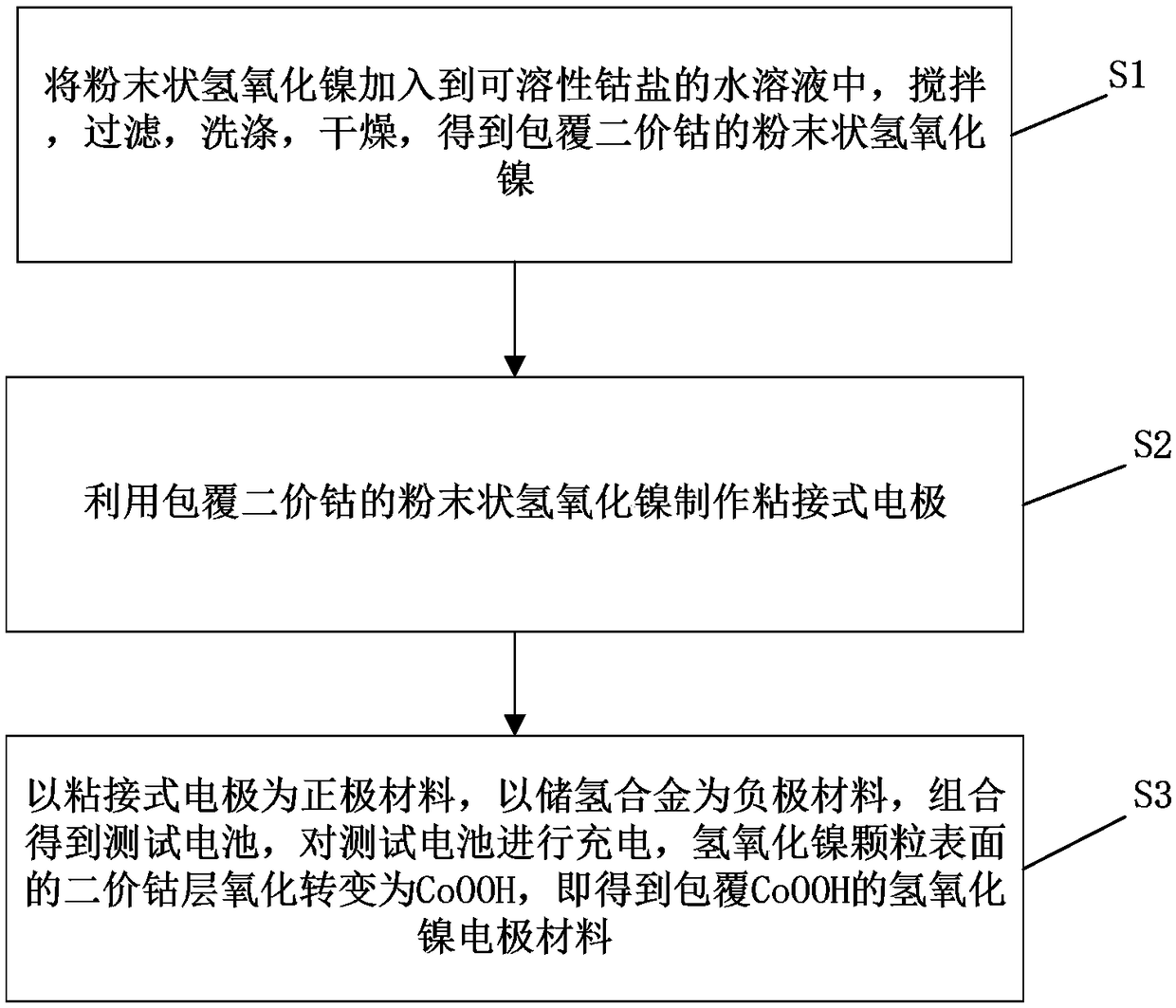

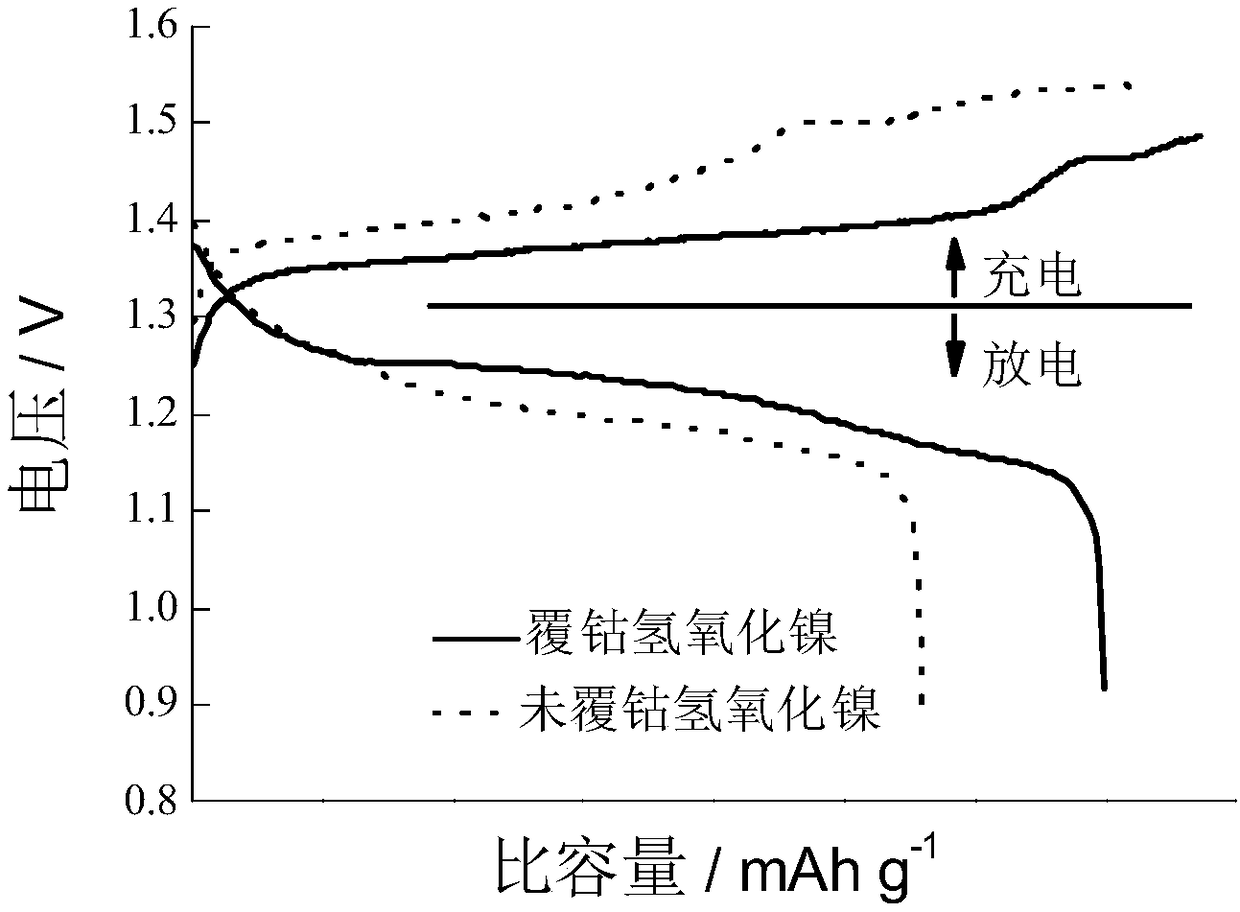

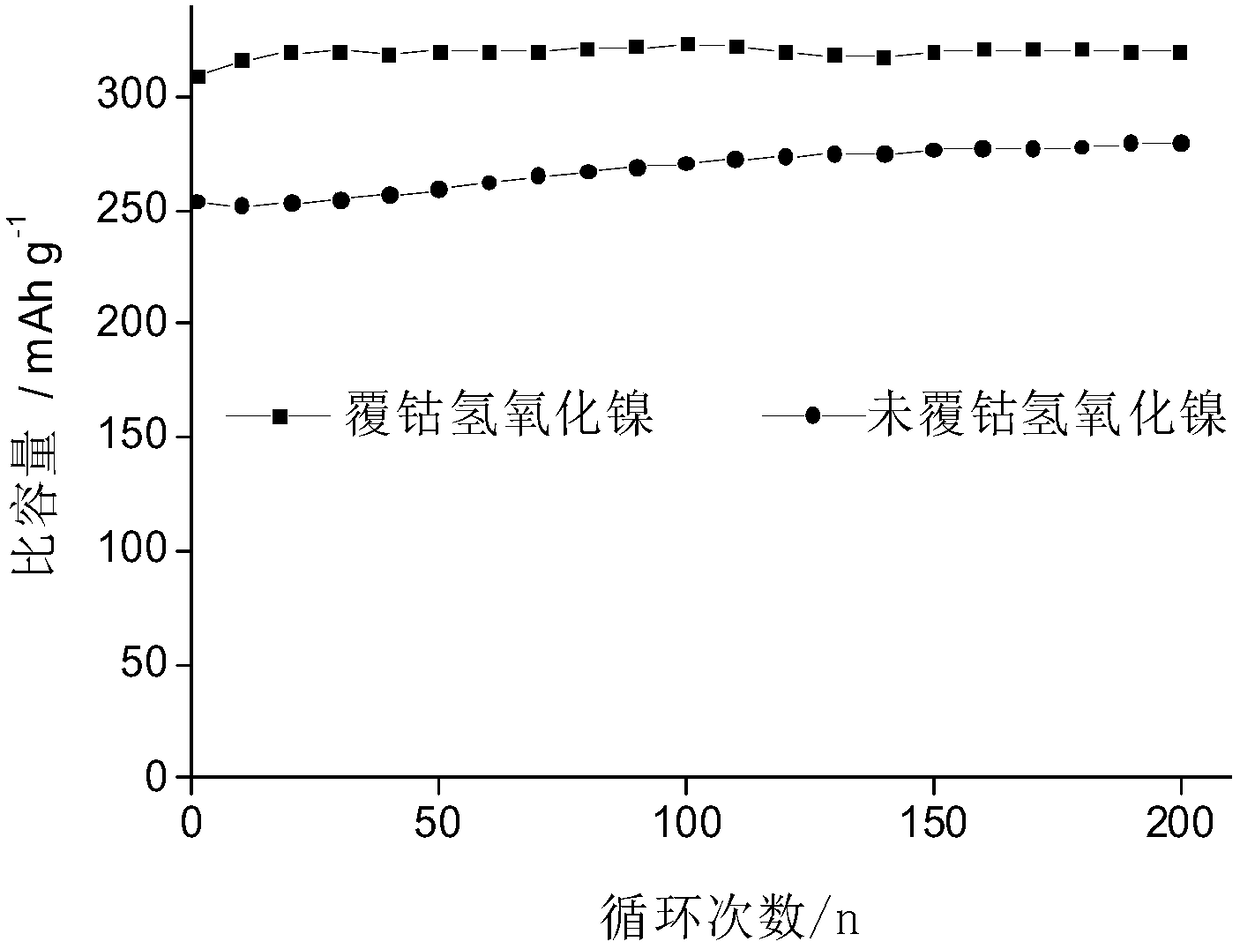

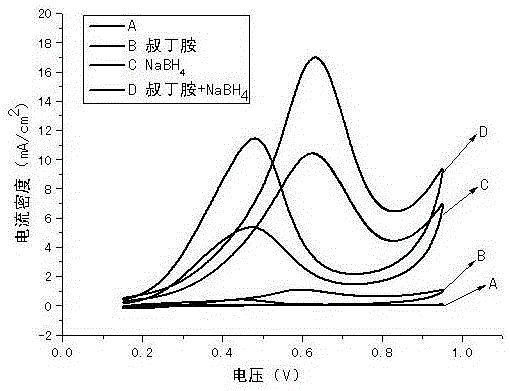

Method for improving surface conductivity of nickelous hydroxide

InactiveCN108565415ATightly bondedImprove conductivityCell electrodesNickel accumulatorsSurface conductivityNickel oxide hydroxide

The invention provides a method for improving the surface conductivity of nickelous hydroxide. The method includes the steps of adding powdery nickelous hydroxide to a water solution of dissoluble cobalt salt for cation exchange between nickel ions on the surface of the powdery nickelous hydroxide and cobalt ions in a water solution phase to form a replacement layer, and forming a CoOOH wrapping layer with conductivity on the surface of nickelous hydroxide through anodic polarization and oxidization, thereby improving the surface conductivity of nickelous hydroxide. The nickelous hydroxide electrode material prepared through the method for wrapping CoOOH has the advantages of being high in conductivity, high in charging and discharging reaction reversibility, good in large-current chargingand discharging performance and good in circulation performance.

Owner:武汉倍特利科技有限公司

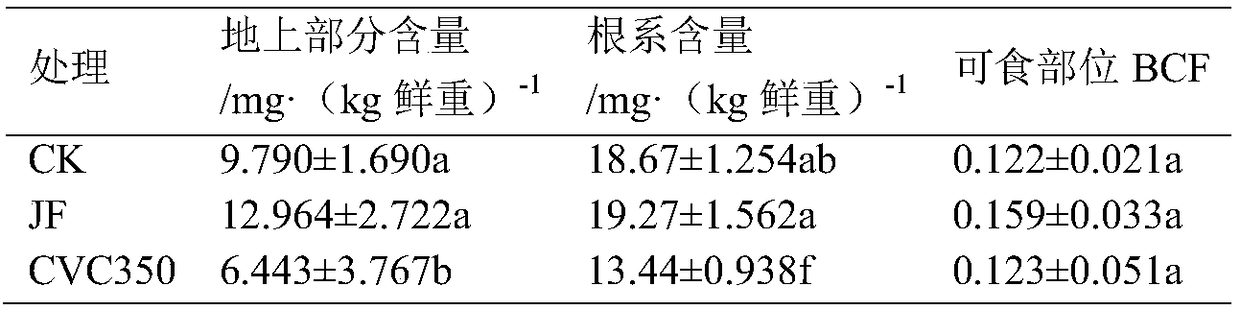

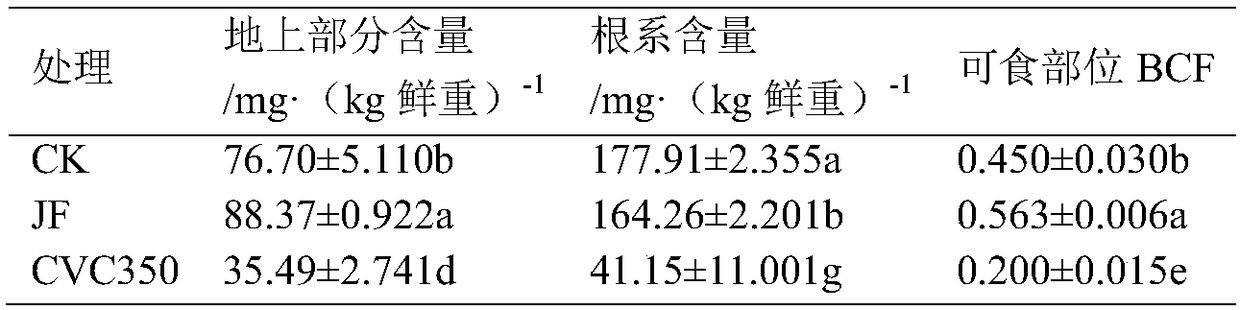

Earthworm excrement-based inhibition and control agent for vegetable-field soil Cu/Zn pollution as well as preparation method and application of earthworm excrement-based inhibition and control agent

InactiveCN109158079ASolve problems such as accumulation pollutionFertilizeOther chemical processesContaminated soil reclamationSoil heavy metalsMigration inhibition

The invention provides an earthworm excrement-based inhibition and control agent for vegetable-field soil Cu / Zn pollution as well as a preparation method and application of the inhibition and controlagent in migration inhibition and control of vegetable-field soil Cu / Zn pollution. The earthworm excrement-based inhibition and control agent is a preparation which has the advantages that raw materials are easy to obtain, and the inhibition and control agent is low in cost, simple in formula and good in application effect, can be prepared from livestock excrement as a main raw material and used as a vegetable-field soil heavy metal inhibition and control agent can, and is of great significance for livestock excrement reclamation and migration inhibition and control of vegetable-field heavy metals; and the earthworm excrement-based inhibition and control agent provided by the invention is environmentally-friendly, possible in on-scale production and convenient to use.

Owner:HANGZHOU NORMAL UNIVERSITY

Preparation method of chromatographic-grade methyl tert-butyl ether

The invention discloses a preparation method of chromatographic-grade methyl tert-butyl ether. The preparation method includes subjecting a sodium hypochlorite solution and industrial-grade methyl tert-butyl ether to refluxing reaction to generate high-boiling-point chlorohydrin and then glycol under the protection of nitrogen; drying the glycol by anhydrous calcium chloride to remove moisture and alcohol impurities; rectifying to obtain the chromatographic-grade methyl tert-butyl ether. The preparation method of the chromatographic-grade methyl tert-butyl ether has the advantages of classical process, easiness in operation, stability, cheap raw materials, easy availability and suitability for large-scale operation, and the purity of the obtained chromatographic-grade methyl tert-butyl ether can be higher than 99.99%.

Owner:SINOPHARM CHEM REAGENT

A method for extracting melanin from cuttlefish juice

The invention relates to the field of pigment extraction technology, in particular to a method for extracting melanin from cuttlefish juice by using enzymes. Specifically, the cuttlefish juice is filtered to remove impurities, dried or freeze-dried to obtain powder, and the melanin is extracted with enzymes. The ink melanin obtained by the method of the invention has high extraction rate and good purity. The method is simple to operate, environmentally friendly and efficient, and is suitable for large-scale operation of extracting high-purity melanin from cuttlefish juice.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Substrate for raising seedlings and its preparation method

ActiveCN106472280BLow costEasy to manageCultivating equipmentsSoilless cultivationMicroorganismSludge

The invention belongs to the technical field of matrix preparing, and particularly relates to a matrix for culturing seedlings and a preparing method thereof. The matrix for culturing seedlings is prepared from biomass sludge, straw light ash, organic wastewater and a microorganism fermenting agent. The matrix for culturing seedlings is economical, efficient and good in safety, healthy seedling cultivating is facilitated, the matrix is not influenced by the weather, and application prospects are good.

Owner:ANHUI GEYI CYCLIC ECONOMY IND PARK

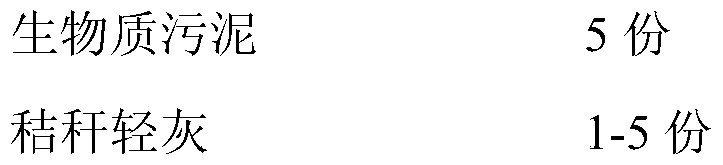

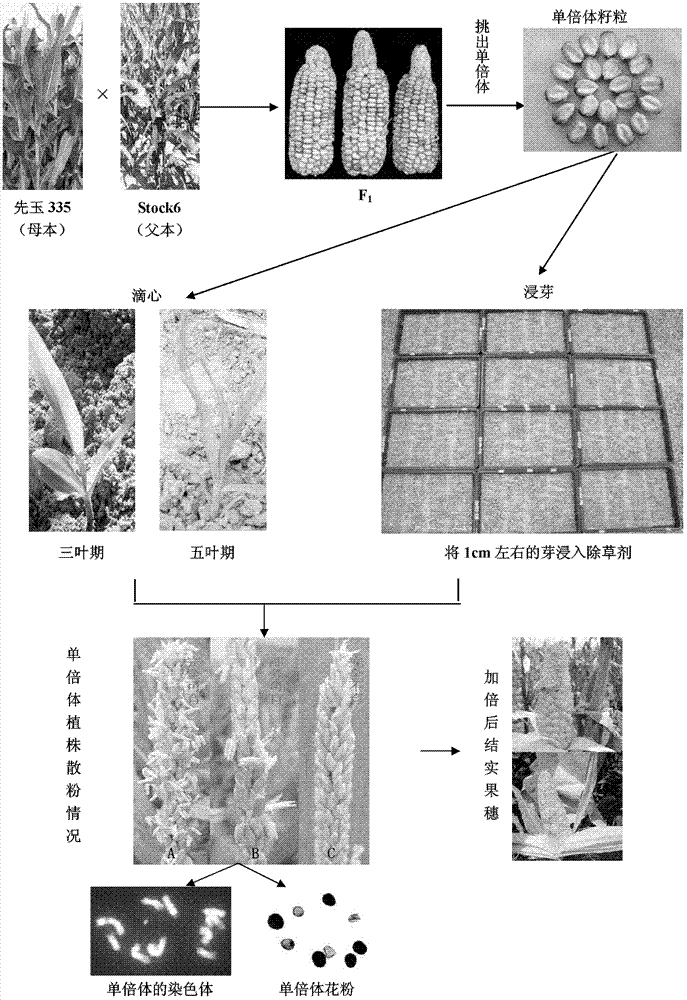

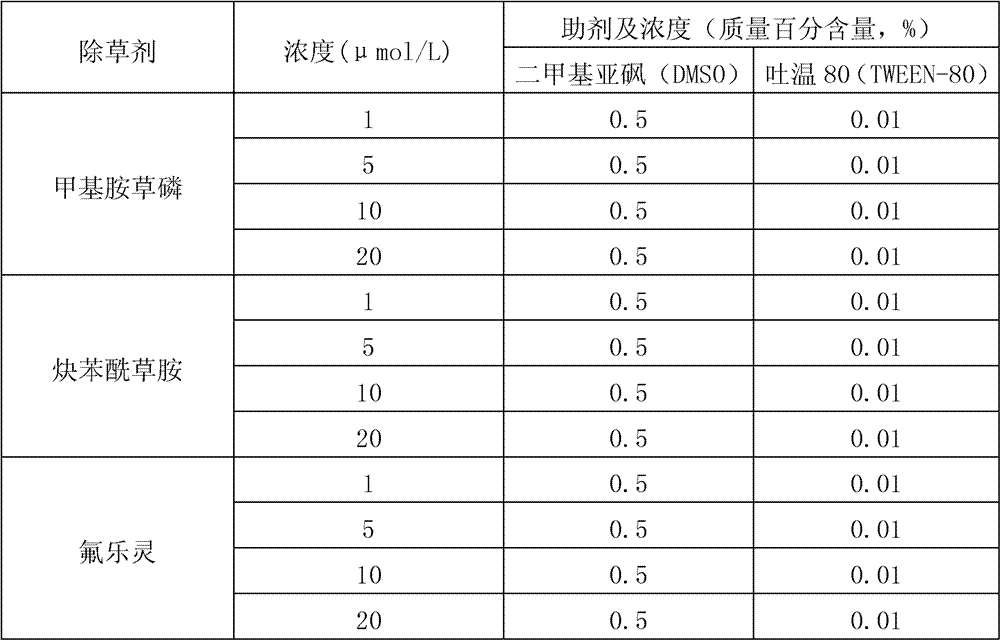

Method for doubling corn haploid by herbicide and special herbicide of method

ActiveCN103053414BResidue reductionEasy to degradeBiocideAnimal repellantsChemical compoundColchicine

The invention discloses a method for doubling corn haploid by a herbicide and the special herbicide of the method. According to the method for doubling the corn haploid, the corn haploid is processed by the special herbicide to obtain corn diploid; and an active ingredient of the special herbicide is any one of the following chemical compounds: amiprophos-methl, propyzamide and trifluralin. The special herbicide consists of the active ingredient of the special herbicide, accessory ingredients and water; and the accessory ingredients consist of dimethyl sulfoxide and TWEEN-80 or dimethyl sulfoxide, TWEEN-80 and thienone. The special herbicide provided by the invention causes small environment pollution and is low in toxicity and residue and prone to degradation, and the dead rate of seedlings is 0 after the corn haploid is processed by a center dropping method with the special herbicide. The method is simple, convenient and efficient, and the doubling rate can reach 27.9%; and the doubling rate of the corn haploid processed by a bud immersion method with the special herbicide can reach 17.9%, and the dead rate of seedlings is obviously lower than that of the seedlings processed by colchicine. The method and the herbicide are suitable for large-scale operation, and can be applicable to large-scale breeding of the corn haploid.

Owner:CHINA AGRI UNIV

A kind of preparation method and application of fucoxanthin

InactiveCN104003962BImprove securityIncrease nutritionOrganic chemistryFatty substance preservation using additivesFucoxanthinPectinase

The invention discloses a preparation method and application of alga xanthophyll. Kelp residue wall breaking is performed by biological enzymolysis to obtain wall-broken kelp residue dry powder, a used compound enzyme preparation is a mixture of pectinase and cellulose with the ratio of W / W= 1:1, the wall-broken kelp residue dry powder is extracted by an alkaline organic solvent, a supernatant and a kelp precipitate are respectively collected; the supernatant pH value is adjusted to neutral, the supernatant is centrifuged, a supernatant is removed, and an alga xanthophylls crude extract product is obtained by 12h of vacuum freeze drying of the precipitate; then an organic solvent and silica gel chromatography column are used for purification, and the alga xanthophylls can be obtained by vacuum concentration and vacuum drying. The alga xanthophylls prepared by the preparation method has a yield reaching up to 2.5 wt%, and the preparation method has the advantages of simple operation, environmental protection and high efficiency, and is suitable for large scale production.

Owner:JIMEI UNIV

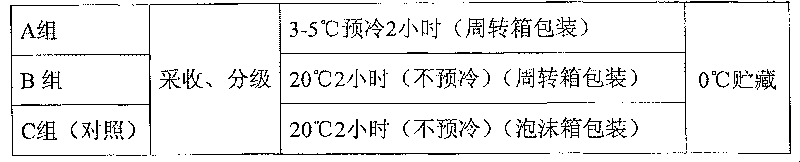

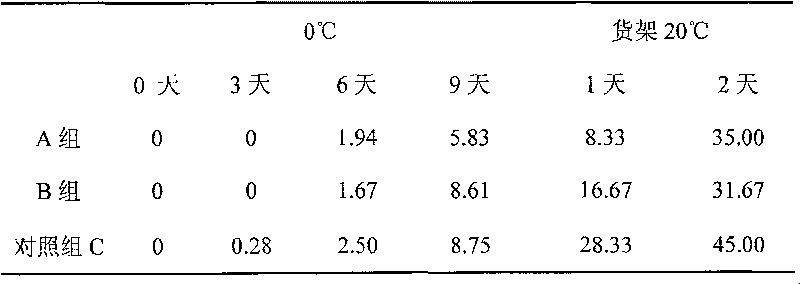

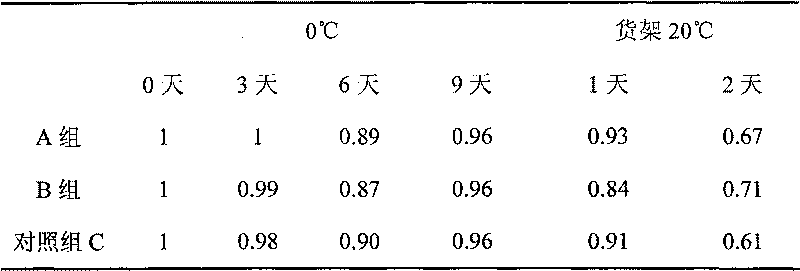

Precooling method based on cold chain storage and transportation of waxberry

InactiveCN101112207BReduce respiratory consumptionReduce decay rateFruits/vegetable preservation by freezing/coolingCold chainPre cooling

The invention provides a pre-cooling method for waxberry fruits cold chain storage and transportation. The method comprises the following steps: (1) the fruits of the same size and maturity and with no mechanical damage are chosen. (2) the fruits are pre-cooled under a low temperature of 3-5 DEG C. (3) then the fruits are preserved under a low temperature of 0 DEG C. By adopting suitable pre-cooling method, the invention makes the waxberry fruits be processed under the low temperature before preserved under the low temperature, which effectively reduces respiration consumption of the fruits and maintains good fruit quality and commodity nature and fruit rot rate in shelf period. The method of the invention is designed reasonably, and operated easily, has low investment cost, and is suitable to large-scaled operation.

Owner:ZHEJIANG UNIV

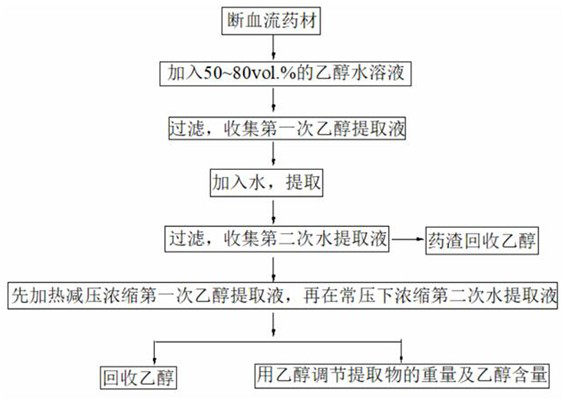

Extraction method of traditional Chinese medicine Duoxueliu

The invention provides a process for extracting traditional Chinese medicine blood flow, comprising: first extracting with 50-85vol.% ethanol as an extraction solvent, decocting with water, and finally concentrating. Adopting the method of the invention can increase the content of Budiaoside Ⅳb in the Duanxueliu extract, and has a simple process and can be used in continuous production.

Owner:LIUZHOU LIANGMIANZHEN

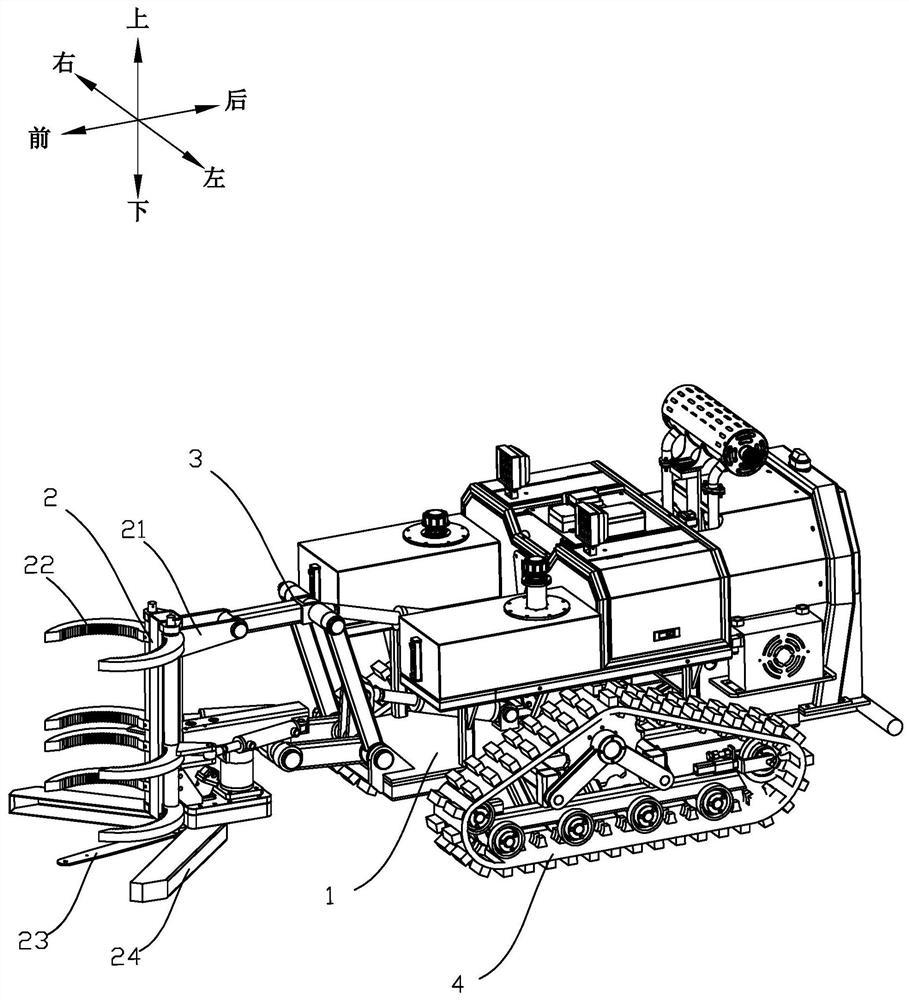

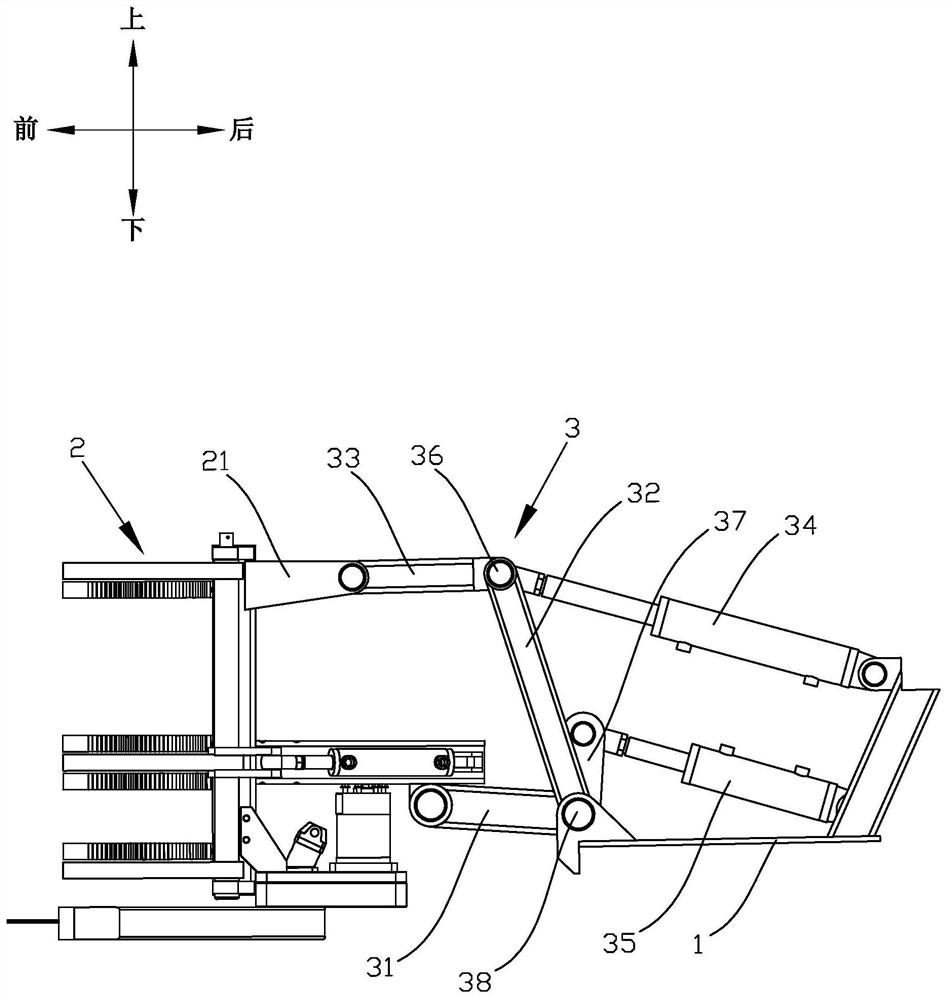

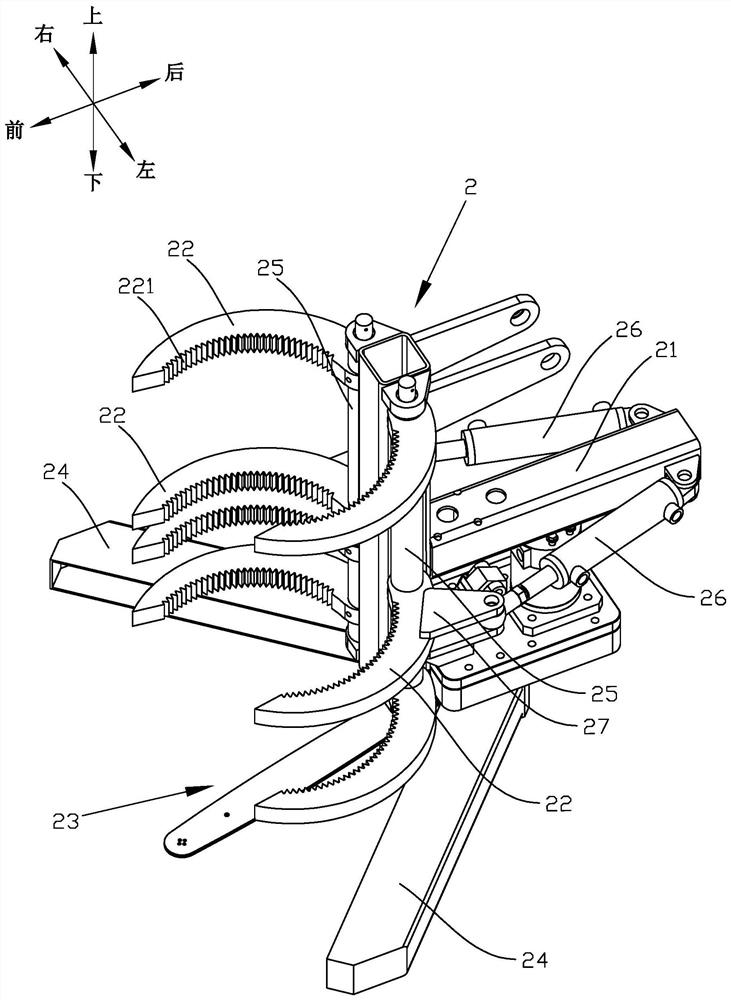

Wood cutting robot

PendingCN113100012AProcess safetyImprove efficiencyEndless track vehiclesForestryVehicle frameTree trunk

The invention discloses a wood cutting robot. The wood cutting robot comprises a frame, a felling device, and a driving device; the felling device comprises a support, a movable clamping jaw and a cutting mechanism; the movable clamping jaw and the cutting mechanism are installed on the support; the cutting mechanism is located below the movable clamping jaw; the driving device is arranged at the front end of the frame and connected with the support; and the driving device can drive the support to move forwards and backwards, ascend, descend and rotate. During felling operation, the robot moves to a position near a trunk through the frame, the driving device drives the felling device to move to the trunk, the driving device reasonably adjusts the angle of the movable clamping jaw and the angle of the cutting mechanism through the support in consideration of growth inclination angles of some trunks, the trunk is held and fixed through the movable clamping jaw, then the cutting mechanism is used for cutting the bottom of the trunk until the trunk is cut off, then the trunk is conveyed to a placement point, the driving device drives the support to rotate by an angle similar to a head lowering action, the trunk can be toppled forwards by loosening the movable clamping jaw, the whole process is safe and reliable, and the efficiency is very high.

Owner:珠海巧力林业机械科技有限公司

A kind of root grafting propagation method of Camellia oleifera in autumn

Owner:GUANGXI FORESTRY RES INST

Preparation method of fucosan

The invention discloses a preparation method of fucosan. On the basis of the traditional preparation technology of the fucosan, HCl is adopted to adjust the pH value of solution, and metal chelating agent EDTA is added, so as to lead heavy metal ions originally chelated on the fucosan sulfate groups to shed off and form chelates with the EDTA. By adopting an ultrafiltration technology, the EDTA-heavy metal chelates are separated from the fucosan, and concentrated, and the fucosan after the removal of heavy metal elements can be prepared through freeze-drying. The preparation method has the advantages of simple operation, mild conditions, high shedding rate of heavy metal ions, low cost and the like, and is suitable for large-scale operations.

Owner:JIMEI UNIV

A kind of cleaning method of polyvinyl pyrrolidone on the surface of nanometer ptpd alloy material

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Method for purifying velardon by using metallic affinity membrane

InactiveCN101270351BSuitable for large-scale operationWide variety of sourcesHydrolasesPeristaltic pumpSodium hydroxide

Owner:DONGHUA UNIV

A kind of preparation method of chromatographic grade methyl tertiary butyl ether

ActiveCN106349029BProcess classicEasy to operateEther separation/purificationPolymer scienceHypochlorite

Owner:SINOPHARM CHEM REAGENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com