A kind of preparation method and application of fucoxanthin

A technology of fucoxanthin and compound enzyme preparation, which is applied in the direction of using additives to preserve fat substances, organic chemistry, and fat production, so as to achieve good anti-oxidation effect, high safety, and improve safety and nutrition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

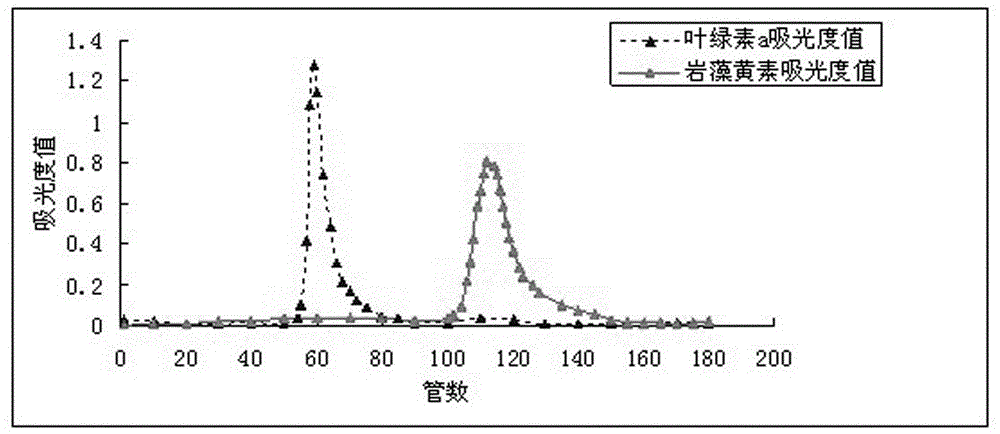

[0040] Example 1: Preparation of fucoxanthin by saponification-organic solvent simultaneous extraction

[0041](1) Laminaria scum is dried in an oven at 80° C. for 5 hours, pulverized by an ultrafine pulverizer, and passed through an 80-mesh sieve to obtain dry kelp slag powder; the dry kelp slag powder is mixed with an enzyme compound enzyme preparation (pectinase: cellulose = 1:1, w / w) according to the weight ratio of 10000:5, add deionized water according to the weight / volume ratio of 1:15, enzymolysis at room temperature for 5h, centrifuge (3000r / min, 5min), and collect the precipitate The product was dried in an oven at 80°C for 6 hours to obtain the dry powder of kelp slag after the wall was broken, and set aside;

[0042] (2) Mix petroleum ether and ethanol at a volume ratio of 2:1, and add NaOH to the mixed organic solvent at a mass volume ratio of 1%, mix well, and use it as an extractant for extracting fucoxanthin for subsequent use;

[0043] (3) Weigh 500g of kelp ...

Embodiment 2

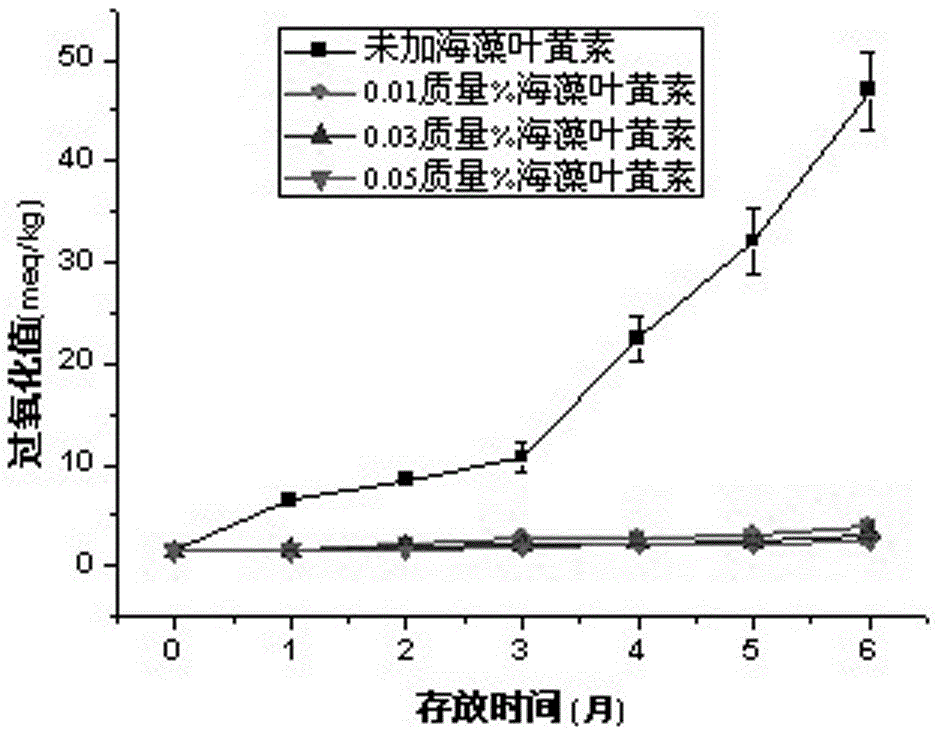

[0046] Example 2: Fucoxanthin improves the antioxidant effect of edible oils

[0047] (1) Antioxidative effect of fucoxanthin on peanut oil

[0048] Weigh 10g of peanut oil respectively and put them into three 50mL conical flasks, respectively add 0.01 mass%, 0.03 mass% and 0.05 mass% of the fucoxanthin prepared by the present invention into the peanut oil, fully dissolve them, and put them in a constant temperature oven at 25°C , take samples regularly, and use the method in the national standard GB5538-85 to measure the peroxide value of oil, the results are as follows image 3 shown. The results show that the peanut oil without fucoxanthin is prone to lipid peroxidation reaction at 25°C, and with the prolongation of storage time, the peroxide value increases more greatly; when fucoxanthin is added, with the storage time The extension of its peroxide value decreased significantly; through the 6-month storage experiment, when the addition amount of fucoxanthin was respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com