A kind of cleaning method of polyvinyl pyrrolidone on the surface of nanometer ptpd alloy material

A technology of polyvinyl pyrrolidone and alloy materials, which is applied in the cleaning field of polyvinyl pyrrolidone (hereinafter referred to as PVP), can solve the problems of reducing the catalytic activity of nano-PtPd alloy materials, and achieve a simple and easy cleaning method, Good effect and improved electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

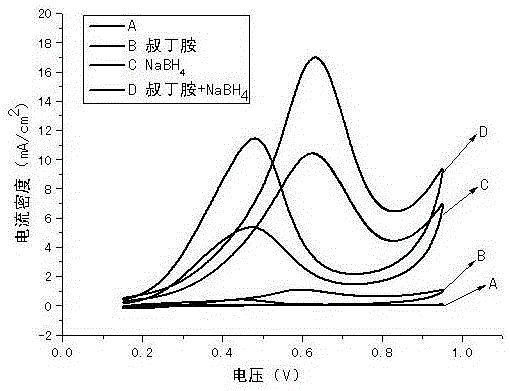

[0026] A cleaning method of surfactant PVP on the surface of a nanometer PtPd alloy material, specifically comprising the steps of:

[0027] (1), preliminary cleaning

[0028] Get 6mg nano-PtPd alloy material, the nano-PtPd alloy material is washed successively with a mixture of acetone and ethanol that is 9000 times the quality of the nano-PtPd alloy material, and centrifuged four times to remove the PVP on the surface of the nano-PtPd alloy material;

[0029] The mixed solution composed of acetone and ethanol is calculated by volume ratio, that is, ethanol: acetone is 1:3;

[0030] (2), the nano-PtPd alloy material that has been preliminarily cleaned in step (1), at room temperature and under stirring conditions, add a mixture of sodium borohydride and tert-butylamine that is 3,500 times the mass of the nano-PtPd alloy material, and then clean and centrifuge again. , to remove the remaining PVP adsorbed on the surface of the nano-PtPd alloy material;

[0031] The mixed sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com