Preparation method of chromatographic-grade methyl tert-butyl ether

A methyl tert-butyl ether, chromatographic-grade technology, applied in the field of preparation of chromatographic-grade methyl tert-butyl ether, can solve the problems of high cost and complicated operation steps, and achieve the effect of easy operation, classic process and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

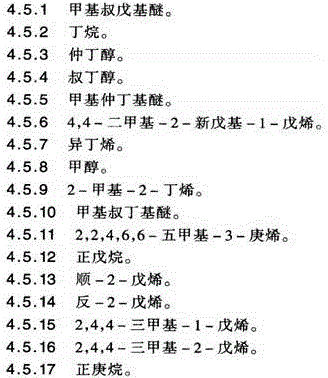

Image

Examples

Embodiment 1

[0024] (1) In a 5L three-neck flask with stirring, condensation and thermometer, under nitrogen protection, put 3 liters of industrial grade methyl tert-butyl ether (about 2220g) and 120g of sodium hypochlorite solution, heat, stir and reflux for 2 hours to generate chlorohydrins, And under alkaline hydrolysis to generate diol soluble in water;

[0025] (2) Cool the mixture of the reactants of industrial-grade methyl tert-butyl ether and sodium hypochlorite solution in step (1) to below 10°C, let it stand for 0.5 hours, and separate the phases; the water phase is used for wastewater treatment;

[0026] (3) Add 240g of anhydrous calcium oxide to the organic phase, and dry it under ultrasonic waves at room temperature for 1 hour;

[0027] (4) standing and microfiltration to obtain purified and dried methyl tert-butyl ether, wherein the methyl tert-butyl ether does not contain olefins and alcohols;

[0028] (5) Under the protection of nitrogen, add dry methyl tert-butyl ether in...

Embodiment 2

[0031] (1) In a 5L three-necked flask with stirring, condensation and thermometer, under the protection of nitrogen, put 3 liters of industrial grade methyl tert-butyl ether (about 2220g) and 200g of sodium hypochlorite solution, heat, stir and reflux for 1 hour to generate chlorohydrins, And under alkaline hydrolysis to generate diol soluble in water;

[0032] (2) Cool the mixture of the reactants of industrial-grade methyl tert-butyl ether and sodium hypochlorite solution in step (1) to below 10°C, let it stand for 0.5 hours, and separate the phases; the water phase is used for wastewater treatment;

[0033] (3) Add 180g of anhydrous calcium oxide to the organic phase, and dry it under ultrasonic wave at room temperature for 1 hour;

[0034] (4) standing and microfiltration to obtain purified and dried methyl tert-butyl ether, wherein the methyl tert-butyl ether does not contain olefins and alcohols;

[0035] (5) Distill the dried methyl tert-butyl ether through a rectifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com