Water-saving type compressed natural gas production system and production method thereof

A technology for compressing natural gas and production systems, which is applied in the fields of gas fuel, granular/powder fuel gasification, petroleum industry, etc., can solve the problems of insufficient realization of the value of hydrocarbon elements, and achieve high system production intensity, high yield, The effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

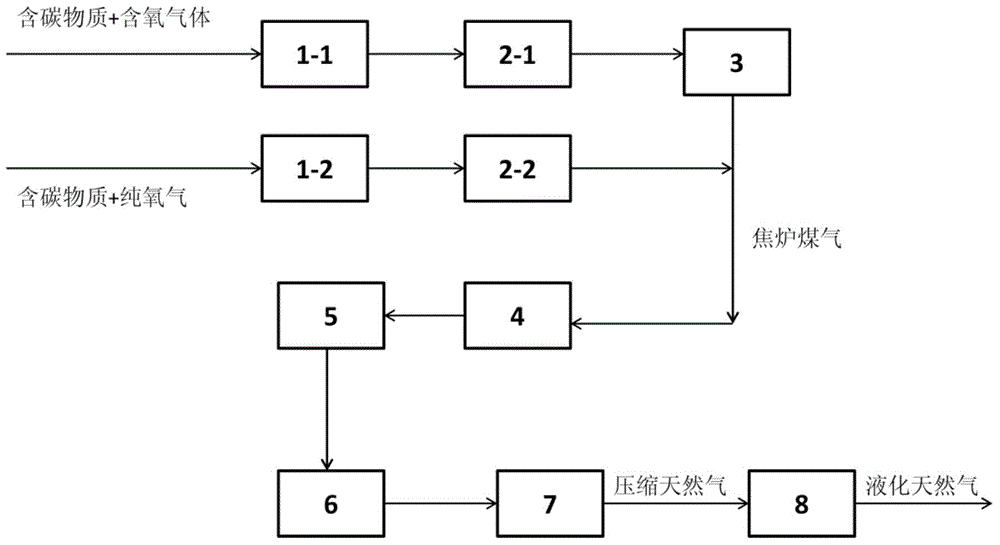

[0051] Coal and air enter the first fixed-bed gasifier for gasification to produce the first crude synthesis gas, and the generated first crude synthesis gas enters the purification unit to remove solid particles and sulfur in the synthesis gas, and then all are sent to the coke oven The unit is used as fuel to replace coke oven gas. In addition, coal and pure oxygen enter the second fixed-bed gasifier for gasification to produce the second crude synthesis gas. After the second crude synthesis gas is purified by the second purification unit, it is mixed with the replaced coke oven gas and then compressed. The unit is further compressed. The compressed mixed gas enters the fine desulfurization unit for desulfurization. The finely desulfurized gas enters the methanation unit for methanation to generate methane, and the generated methane is further purified by mercury removal and drying units to obtain the product compressed natural gas.

Embodiment 2

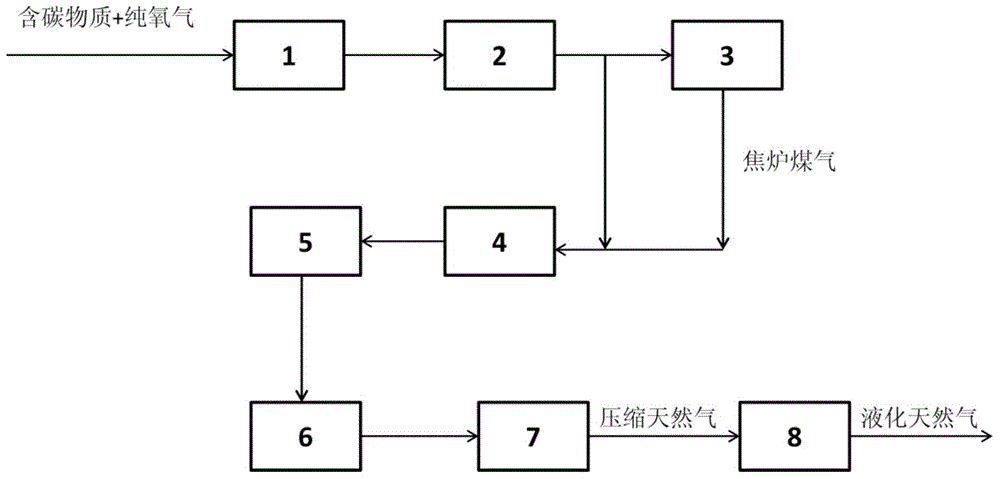

[0053] Coke powder and oxygen enter the fluidized bed gasifier for gasification to produce crude synthesis gas, and the generated crude synthesis gas enters the purification unit to remove solid particles and sulfur in the synthesis gas, and 85% by volume of the purified synthesis gas passes to the coke The furnace unit is used as fuel to replace the coke oven gas, and the remaining 15% by volume is mixed with the replaced coke oven gas and enters the compression unit for further compression. The compressed mixed gas enters the fine desulfurization unit for desulfurization. The finely desulfurized gas enters the methanation unit for methanation to generate methane, and the generated methane is further purified by mercury removal and drying units to obtain compressed natural gas, which is further liquefied to produce liquefied natural gas.

Embodiment 3

[0055] Petroleum coke and gas with an oxygen content of 80% by volume (the rest is nitrogen) enter the first entrained entrained gasifier for gasification to produce the first crude synthesis gas, and the generated first crude synthesis gas enters the first purification unit for desynthesis The solid particles and sulfur in the gas are then all passed to the coke oven unit to be used as fuel to replace the coke oven gas. In addition, petroleum coke and pure oxygen enter the second fixed-bed gasifier for gasification to produce the second crude synthesis gas. After the second crude synthesis gas is purified by the second purification unit, it is mixed with the replaced coke oven gas and then enters the The compression unit further compresses. The compressed mixed gas enters the fine desulfurization unit for desulfurization. The finely desulfurized gas enters the methanation unit for methanation to generate methane, and the generated methane is further purified through mercury ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com