Precooling method based on cold chain storage and transportation of waxberry

A fruit and pre-cooling technology is applied in the field of fruit storage to achieve the effect of reducing the rate of fruit rot, easy operation and suitable for large-scale operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

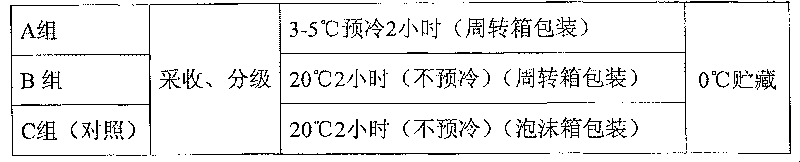

[0009] 'Water chestnut' bayberry (Myrica rubra Sieb. & Zucc) fruits (9 matures) were collected from Xianju County, Zhejiang Province in 2005. After harvesting, the fruits with uniform size, no pests and diseases and mechanical damage were selected, and the following treatments were carried out (see Table 1):

[0010] Table 1 treatment plan

[0011]

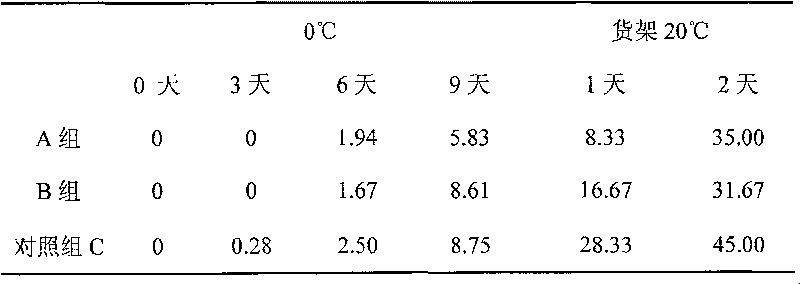

[0012] During the storage and shelf period, the fruit rot rate (360 fruits), appearance color (50 fruits), white spot fruit (50 fruits), fruit taste (50 fruits) and soluble solids (TSS) content, etc. detection. Testing standard:

[0013] ① Appearance color (brightness index): dark: level 0, bright: level 1;

[0014] ② Vitiligo fruit (white spot index): no white spot: level 0, spot area ≤ 10%: level 1, spot area > 10%: level 2;

[0015] ③Fruit taste (odor index): normal: grade 0, odor: grade 1, severe odor: grade 2.

[0016] The inspection results are calculated according to the following formulas to calculate the fruit brig...

Embodiment 2

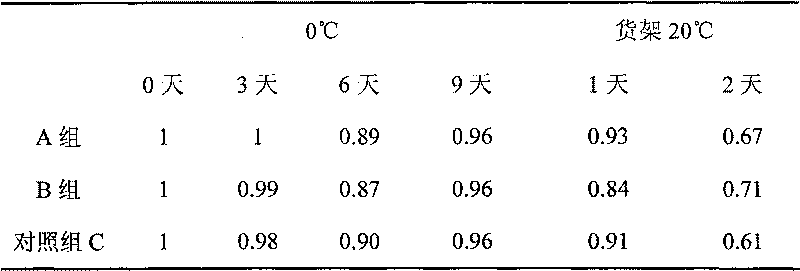

[0022] Pre-processing, grouping, and detection are the same as in Embodiment 1. During the storage of bayberry fruit, if the storage conditions are not conducive to the maintenance of fruit quality, the anthocyanins in the fruit will decompose, lose the original bright luster, and the color will be dark red or faded. Our results showed that there was no significant difference in the fruit vividness index among the three treatments A, B and the control group C during cold storage, but when the fruit was stored at 0°C for 9 days and then transferred to the shelf at 20°C, there was no significant difference between the three treatments. There is a difference in the fruit brightness index, which is better in group A, see Table 3.

[0023] Table 3 Effects of different pre-cooling methods on the appearance color of stored fruits (expressed in vividness index)

[0024]

Embodiment 3

[0026] Pre-processing, grouping, and detection are the same as in Embodiment 1. Waxberry fruit has no exocarp, and the flesh column is soft and vulnerable to mechanical damage. After being injured, the juice will ooze from the injured part, soak the surface of the fruit, and make the injured part partially fade and appear white. Different packaging + pre-cooling treatment is of great significance to reduce the mechanical damage of fruit and reduce the occurrence of white spots on fruit. The results showed that in the first 6 days of storage at 0°C, there was no significant difference in the fruit white spot index among the three treatments; after the ninth day of storage at 0°C, the fruit white spot index of group A was significantly lower than that of group B and control group C, this effect Continue until transferred to a 20 °C shelf, see Table 4.

[0027] Table 4 Effects of different pre-cooling methods on the white spot index during fruit storage

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com