Method for purifying velardon by using metallic affinity membrane

A papain and affinity membrane technology, applied in hydrolase and other directions, can solve the problems of cumbersome process, long separation time, short diffusion path, etc., and achieve the effect of wide source of raw materials, high multiple and high enzymatic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The activation of the nylon membrane and the modification of the bonded chitosan, the specific steps are as follows:

[0027] (1) The nylon membrane was first hydrolyzed in 1M HCl at 25°C for 24 hours, and then activated with formaldehyde. Ten hydrolyzed nylon membranes were immersed in 20ml of formaldehyde solution (>36.5wt.%), added with 0.2ml of phosphoric acid (85wt.%), reacted at 60°C for 7h, and washed with hot water at 40-50°C for several times.

[0028] (2) The above-mentioned formaldehyde-activated nylon membrane is immersed in 10ml of chitosan solution (dissolved with 1vol.% acetic acid) with a mass fraction of 1.5%, reacted at room temperature for 1h, then transferred to an 80°C oven, took it out after 1h, and used 1vol .% acetic acid and deionized water to wash away unreacted chitosan. The content of chitosan on the nylon film can be tested according to the ninhydrin method.

Embodiment 2

[0030] The modified nylon membrane chelates metal copper ions, and the specific steps are as follows:

[0031] (1) The above modified 10 nylon membranes were immersed in 4.6ml of epichlorohydrin, 46ml of 2M sodium hydroxide and 0.017g of sodium borohydride mixture, reacted at room temperature for 2 hours, and then directly added 23ml of oxygen Chloropropane, 46ml of 2M sodium hydroxide, react at 60°C for 12h, and wash with deionized water several times.

[0032] (2) Immerse the above-mentioned cyclopropane-bound membrane into a mixed solution containing 10ml 8.6M iminodiacetic acid (IDA), 0.14g sodium borohydride and 114.4ml 2M sodium carbonate, react at a constant temperature at 60°C for 12h, and use deionized Wash with water, 5vol.% acetic acid and deionized water several times.

[0033] (3) Immerse the above-mentioned film in 500ml of 100ppm copper sulfate solution and react for 2h to obtain a metal film that chelates copper ions.

Embodiment 3

[0035] Use metal chelate membrane to adsorb papain, and optimize the conditions. The specific steps are as follows:

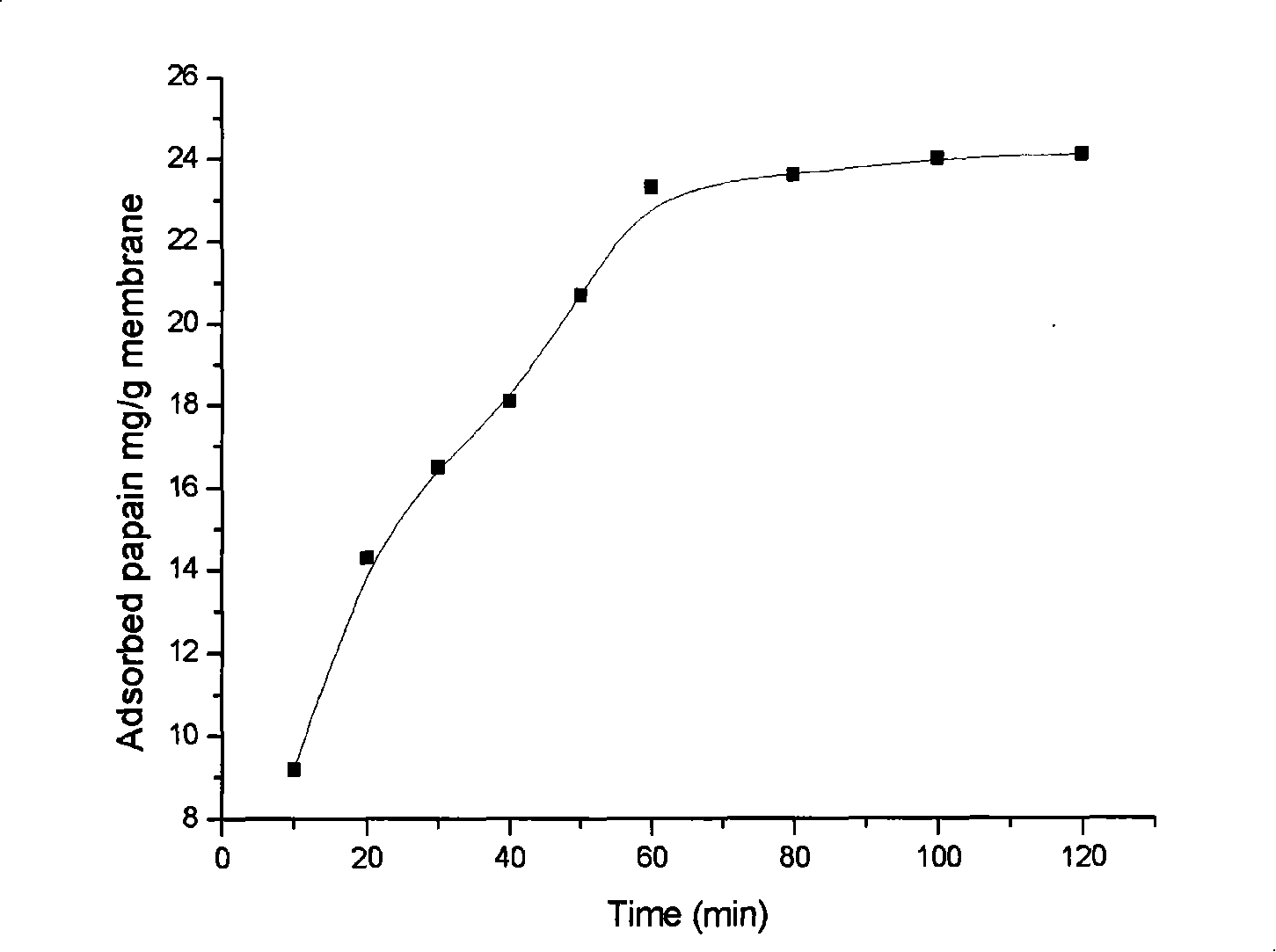

[0036] (1) Determination of reaction time. Stack 10 modified nylon membranes to form a membrane stack, put them into the membrane bridge, and send 100ml of 1.0mg / ml papain Tris-HCl solution (pH=8.5) with a peristaltic pump at a flow rate of 2.0ml / min. 10min, 20min, 30min, 40min, 50min, 60min, 80min and 100min, carry out adsorption, and measure the amount of papain adsorption. Experimental results such as figure 1 , the optimal response time is selected at 60min.

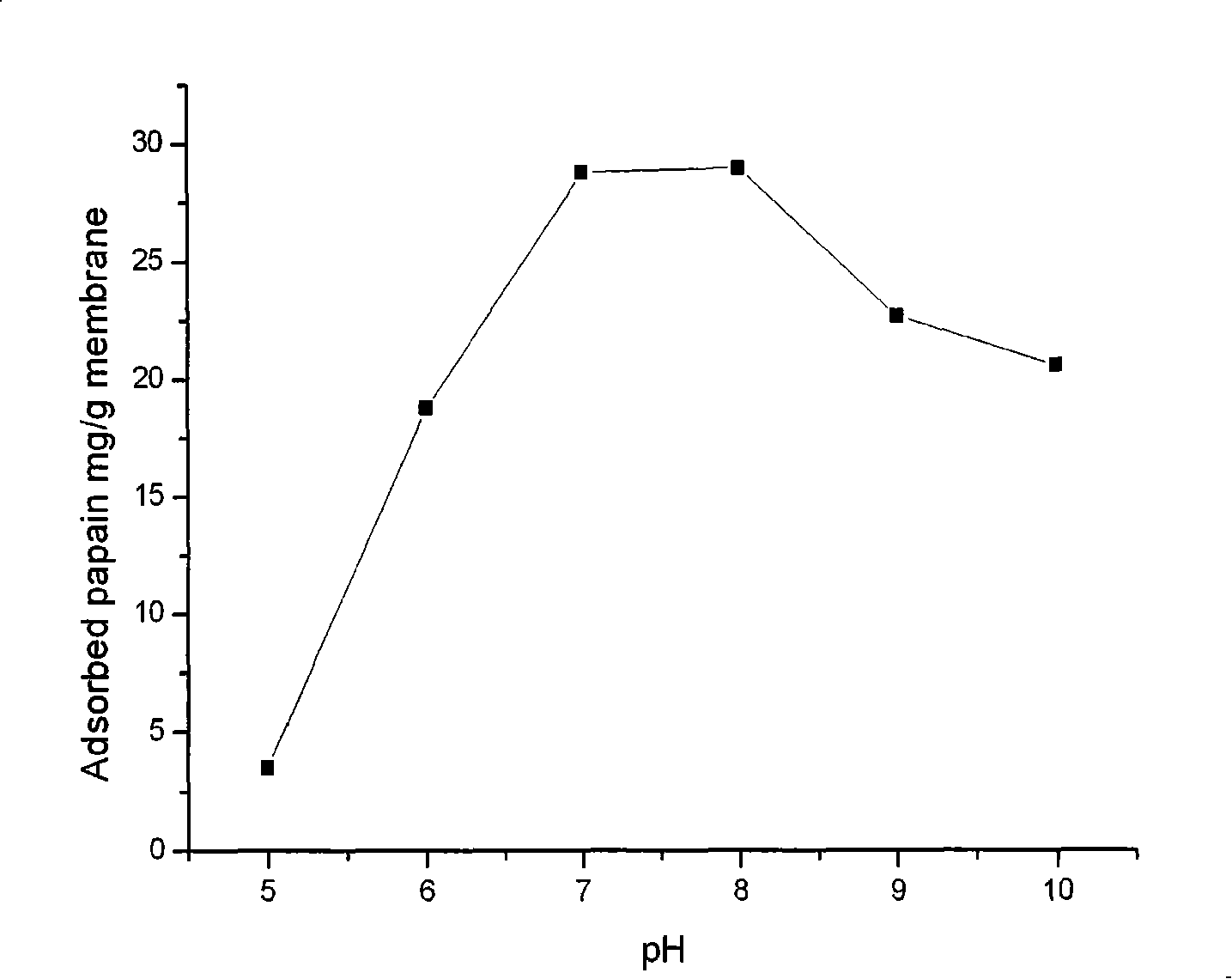

[0037] (2) Determination of reaction pH. Stack 10 modified nylon membranes to form a membrane stack, put them into the membrane bridge, and send 100ml of 1.0mg / ml papain Tris-HCl solution with different pH values into it with a peristaltic pump, and circulate the reaction for 2 hours at a flow rate of 2.0ml / min , adding papain in Tris-HCl solution with pH values of 5.0, 6.0, 7.0, 8.0, 9.0, 10....

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com