An integral walking guardrail template assembly and disassembly machine

A technology of formwork, guardrails, applied in the direction of road safety devices, roads, road repairs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

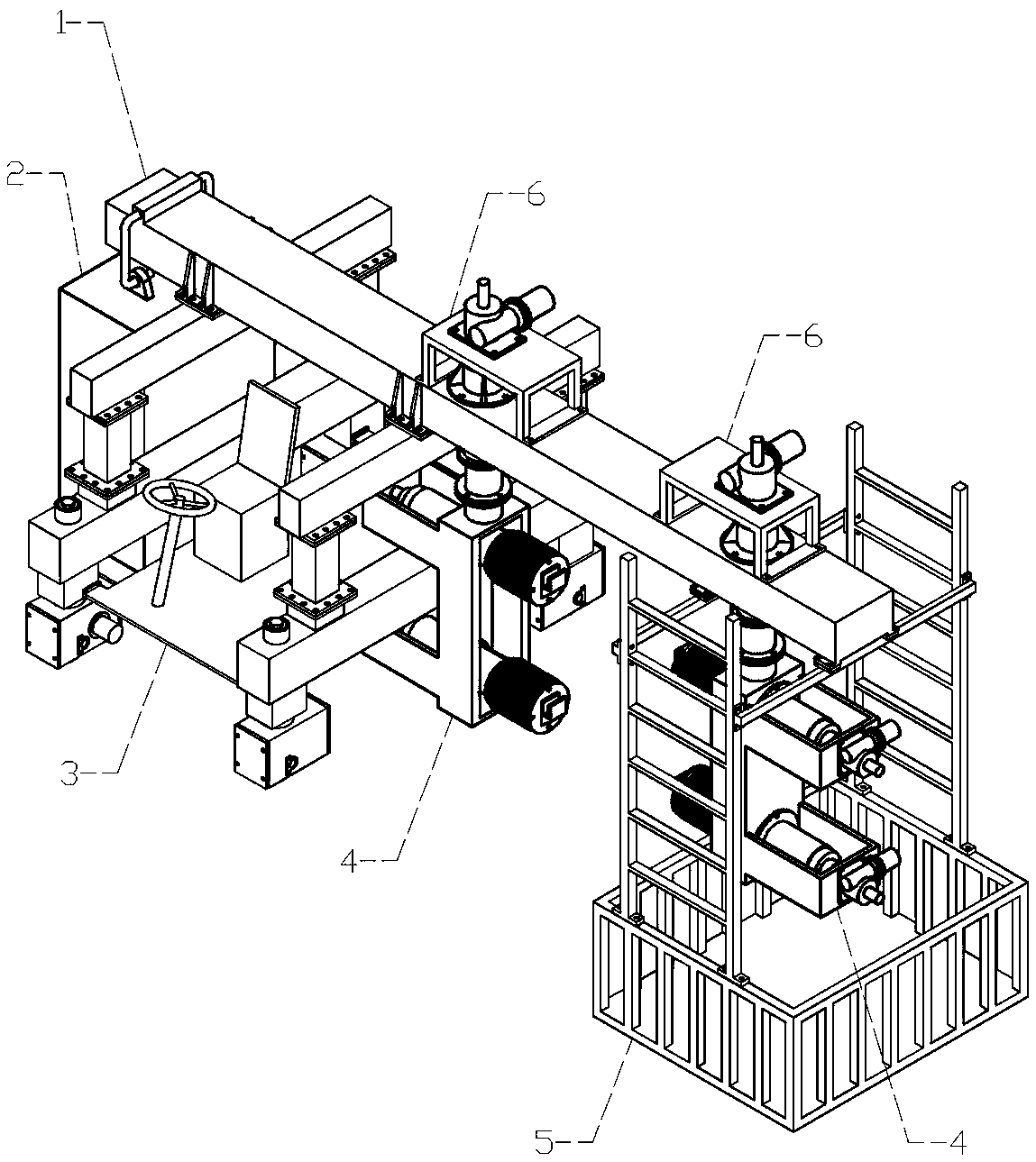

[0031] It can be seen from the content of the invention that a whole walking guardrail template assembly and disassembly machine is composed of main beam 1, counterweight 2, driving control system 3, telescopic cantilever 4, artificial hanging basket 5, and cantilever frame 6; Installed on the left side of the lower part of the main beam 1; the driving control system 3 is installed under the main beam 1; The lower part of beam 1 is on the far right.

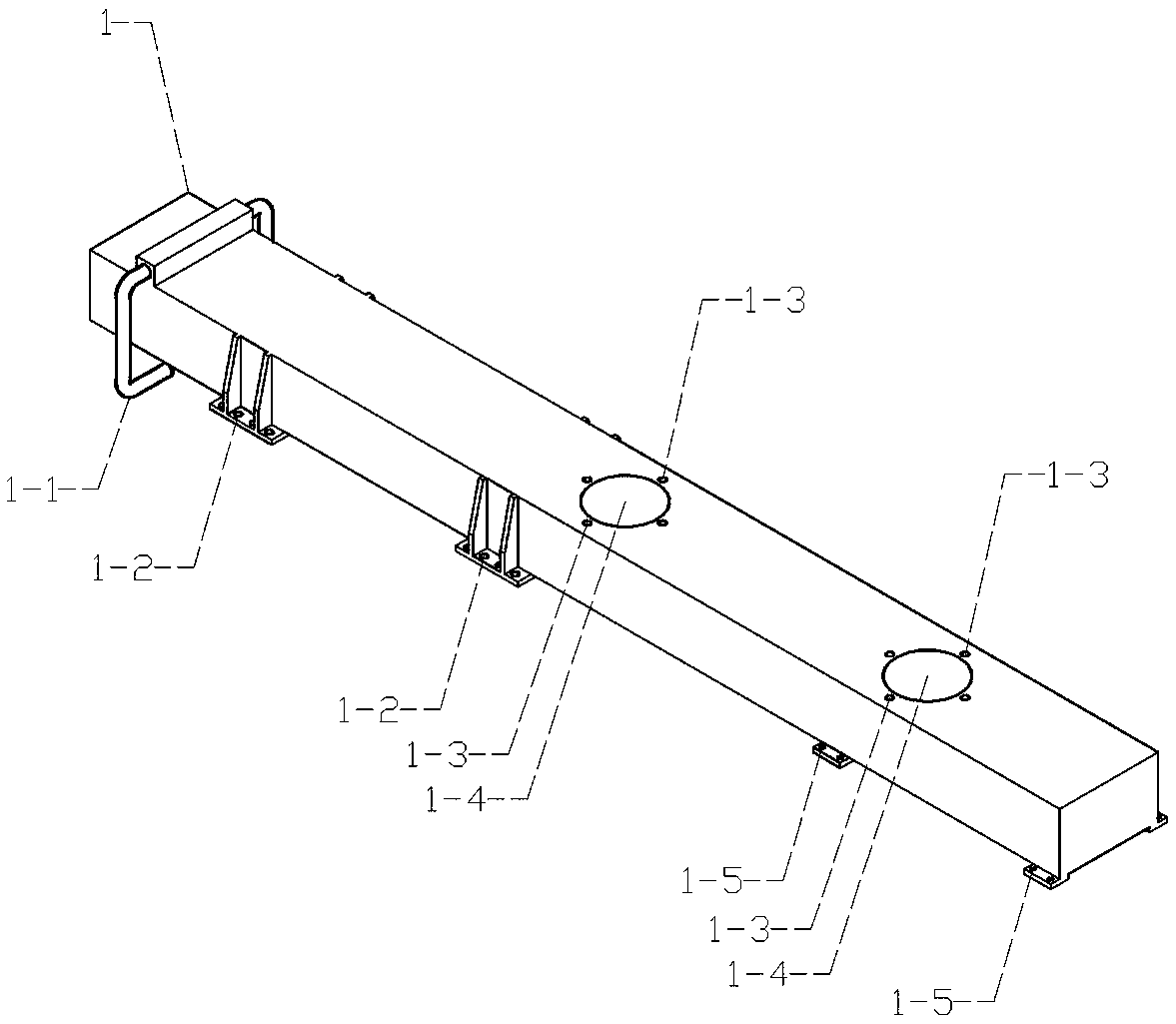

[0032] The main girder 1 of the present invention refers to: the long girder of the main force-bearing member; it is provided with a counterweight installation suspender 1-1, a beam adaptation hole 1-2, a longitudinal guide cylinder adaptation hole 1-3, Adaptive holes 1-4 for the artificial hanging basket, and through holes 1-5 for the longitudinal telescopic cylinder; their function is to carry various loads and transfer them to designated places; its structure is as attached figure 2 As shown, its design position is as attach...

Embodiment 2

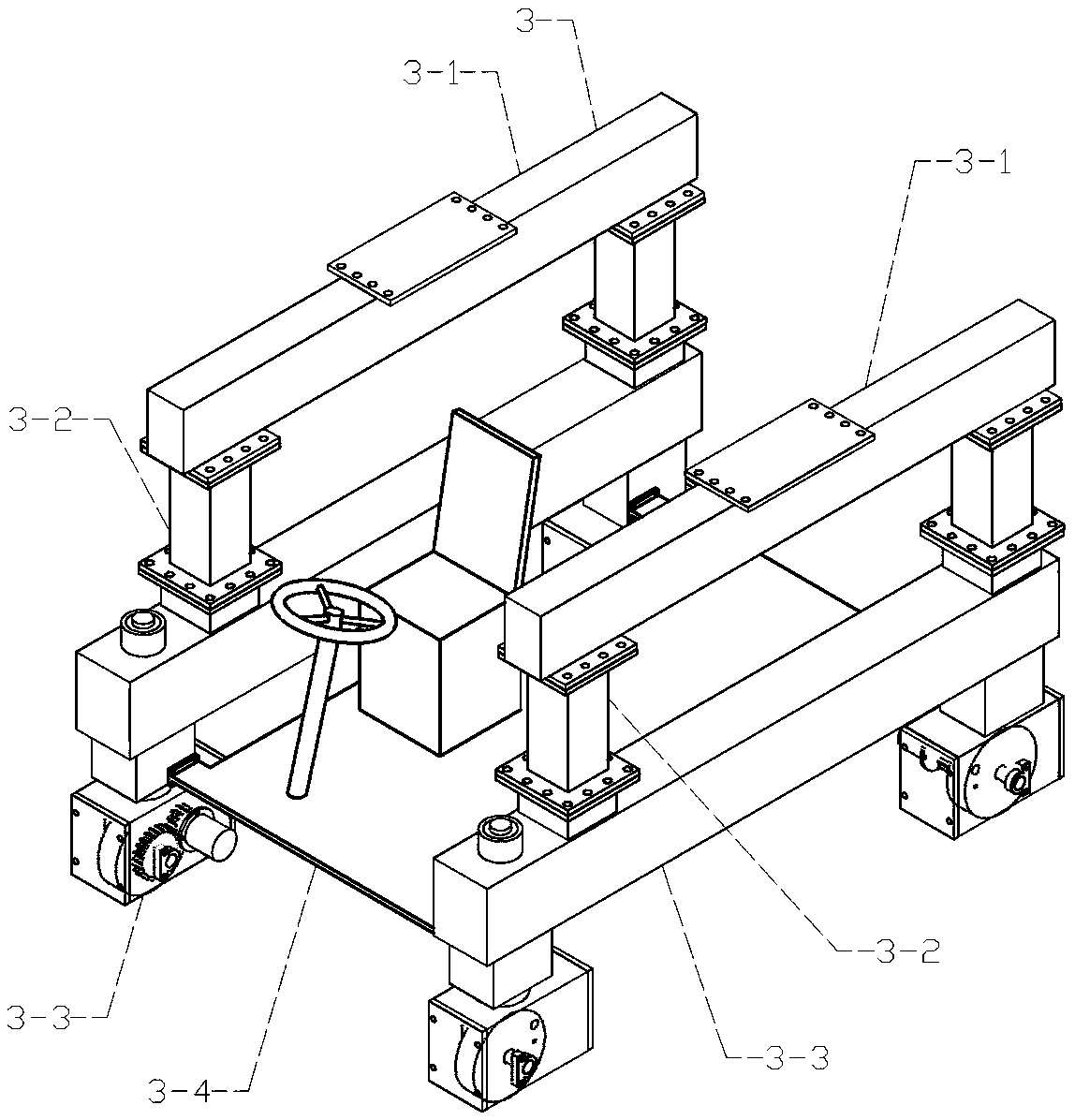

[0039] In order to realize the function of driving equipment and devices to move without completely dismantling the formwork and saving manpower and time, the present invention is provided with a driving control system 3, and a beam 3-1, a support beam 3-2, and a ground beam 3 are arranged on it. -3. The cockpit 3-4; the crossbeam 3-1 is set above the support beam 3-2; the ground beam 3-3, as the load of the whole device, is located at the bottom; the cockpit 3-4 is installed on two ground beams 3 Between -3.

[0040] The crossbeam 3-1 of the present invention refers to: a transverse beam; it is provided with a crossbeam installation hole 3-5 and a support beam adaptation hole 3-6; its function is to support the beam on the main load-bearing member; its structure as attached Figure 4 As shown, its design position is as attached image 3 Shown in Mark 3-1.

[0041]The support beam 3-2 in the present invention refers to: a beam erected; a support beam installation hole 3-7 a...

Embodiment 3

[0045] In order to realize the function of adjusting the required height of the template by adjusting the height in the longitudinal direction, the present invention is provided with a longitudinal screw elevator 4-1 and a longitudinal telescopic cylinder 4-3; Hole 4-7, longitudinal screw elevator connecting seat 4-8; horizontal telescopic frame adaptation hole 4-7 is located at the bottom of longitudinal telescopic tube 4-3; longitudinal screw elevator connecting seat 4-8 is located at the top of longitudinal telescopic tube 4-3 .

[0046] The vertical spiral elevator 4-1 of the present invention refers to: the elevator on the telescopic cantilever 4; Its function is to adjust the lifting of the longitudinal direction according to actual needs; Its design position is as attached Figure 7 Shown in Mark 4-1.

[0047] The longitudinal telescopic cylinder 4-3 of the present invention refers to: the longitudinal telescopic cylinder on the telescopic cantilever 4; it is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com