Installing method of the integral sleeve of a kind of T -bolt (diameter <= 48mm)

A technology of bolt sleeves and bolt diameters, which is applied in basic structure engineering, construction, building construction, etc., can solve the problems of unsatisfactory pre-embedded precision of T-shaped bolt sleeves, etc., and achieve the effect of reasonable design and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

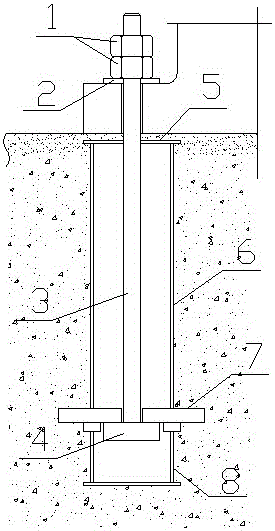

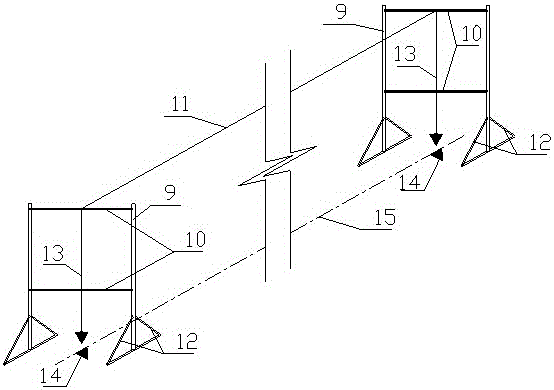

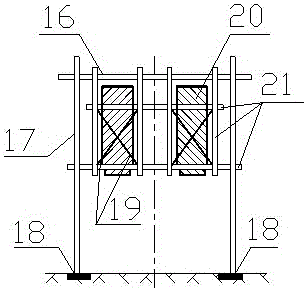

[0035] The installation method of the integral sleeve of the equipment foundation T-bolt diameter ≤ 48mm of the present invention adopts a process flow: measuring and setting out → pre-embedded iron parts on the cushion layer → bottom steel bar construction → installing the center line frame → installing the T-bolt sleeve Support frame→T-bolt sleeve installation→superior reinforcement construction→T-bolt sleeve retest→pour concrete→T-bolt sleeve retest again.

[0036] The integral sleeve installation method of the equipment foundation T-bolt diameter ≤ 48mm of the present invention comprises the following steps:

[0037] a. Pre-embedded (pre-installed) iron parts:

[0038] According to the center position of the sleeve on the design drawing, pre-embed the iron parts on the foundation floor cushion. If it is on the top plate of the foundation, pre-install iron parts on the formwork. When using steel formwork, it is fixed by welding, and when using wooden formwork, it is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com