Automatic grouting construction device with high efficiency

A construction device and high-efficiency technology, applied in infrastructure engineering, building material processing, construction, etc., can solve the problems of low mixing efficiency, inconvenient cleaning, inconvenient operation, etc., to facilitate installation and production, and reduce costs. investment, to achieve the effect of grouting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

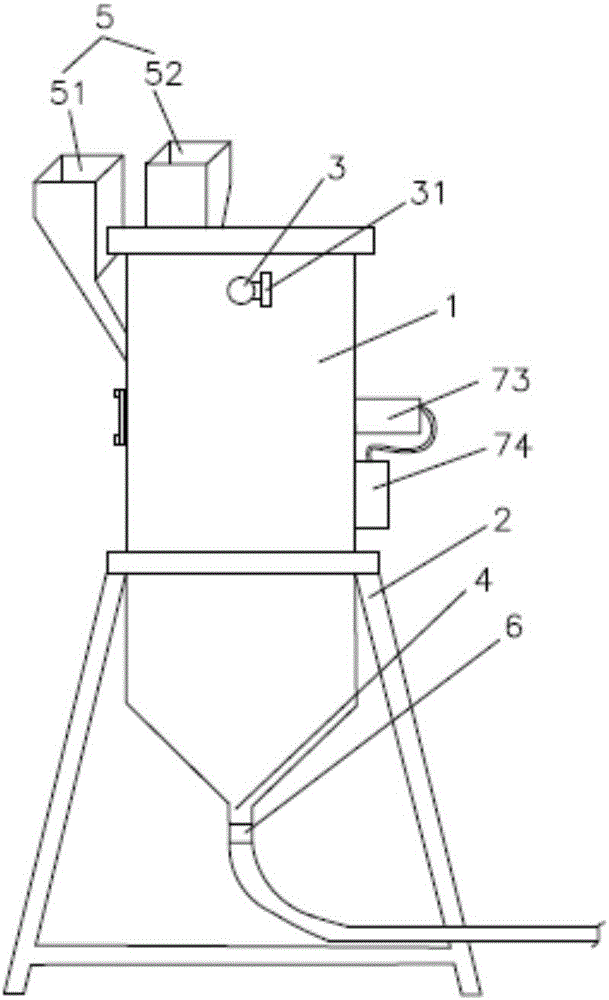

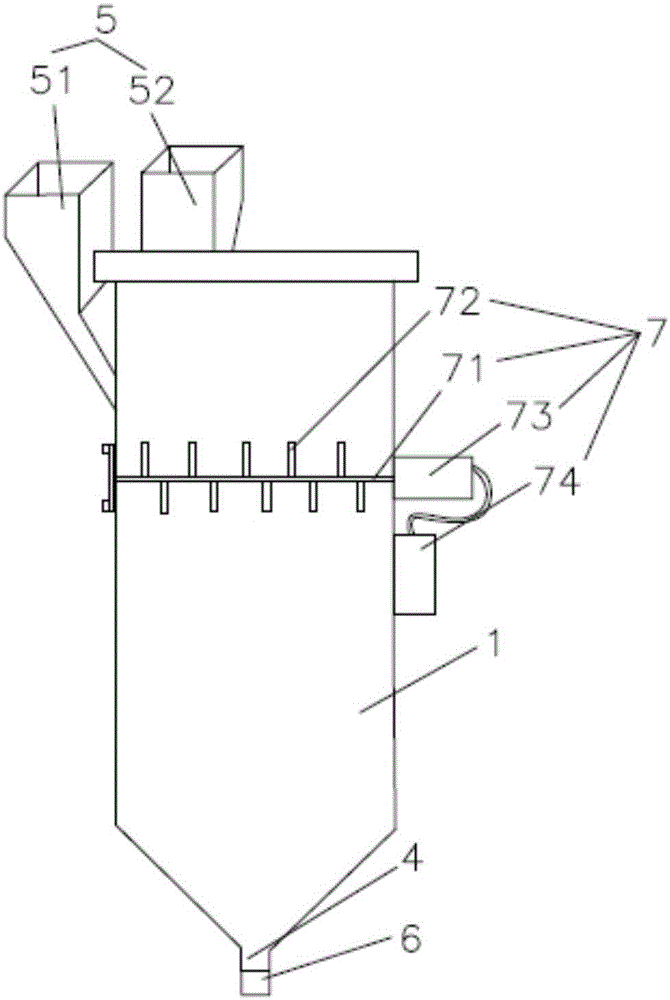

[0012] Such as figure 1 and figure 2 As shown, a high-efficiency automatic grouting construction device includes a barrel 1 and a barrel support frame 2, an air inlet 3 is arranged on the barrel 1, a discharge port 4 is arranged at the bottom of the barrel 1, and the barrel supports The frame 2 is a four-legged support frame welded by angle steel, which is convenient for installation and manufacture. The barrel 1 is connected with a hopper 5, and the hopper 5 is divided into a first hopper 51 and a second hopper 52, and the first hopper 51 and the second hopper 52 They are respectively connected to the barrel 1 through a switch, and the switches are respectively installed at the junction of the first hopper 51 and the barrel 1 and the junction of the second hopper 52 and the barrel 1. The closing of the switch controls whether the slurry in the hopper enters the barrel 1 for mixing, the discharge port 4 is provided with a flow control valve 6 for controlling the flow rate, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com