Nonmetal control box stopper assembly

A limiter and control box technology, applied in the field of auto parts, can solve the problem of rust and wear of the limit box and limit arm, rust and deformation of the limit box and limit arm, and abnormal sound and noise of the door limiter To achieve good economic and social benefits, reduce the demand for layout space, and reduce abnormal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

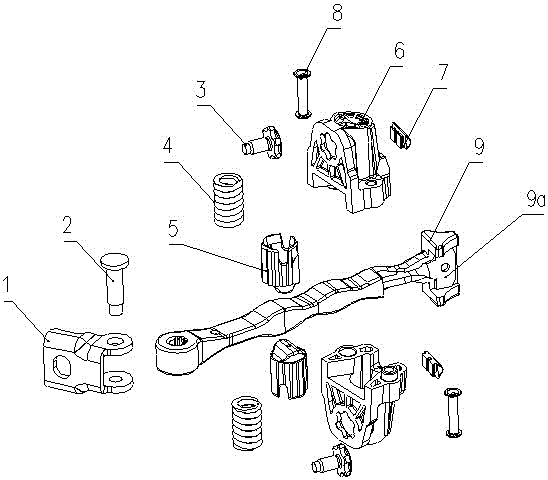

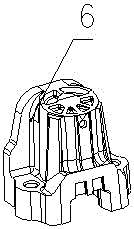

[0027] Embodiment 1, the limiter bracket 1 is fastened on the vehicle body by mounting bolts, the control box 6 is fixed on the door by two screws 3 or nuts, when the door is opened, the control box 6 will pull the plate along the limiter 9 moves, because the stopper pull plate 9 is provided with the structures with different heights through the transition of the inclined surface, the spring 4 will have different elastic deformations.

Embodiment 2

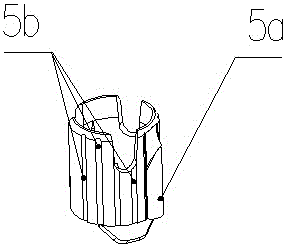

[0028] In the second embodiment, through the cooperation of the slider 5 and the limiter pull plate 9, since the limiter pull plate 9 is provided with a plurality of structures with different heights to form a plurality of limit points, so when the control box 6 passes through its overall symmetrical When the limiting power structure slides axially along the limiter pull plate 9, at each limit point of the limiter pull plate 9, the spring 4 in the limiter power structure undergoes corresponding elastic deformation to generate elastic force, and the force is generated by The elastic force fixes the car door, so as to achieve the purpose of limiting the car door at different limit points.

Embodiment 3

[0029] Embodiment 3, since the slider 5 slides axially along the stopper pull plate 9 with the control box 6, in order to increase the relative friction between the slider 5 and the stopper pull plate 9, it is convenient to fix the stopper pull plate 9 And to ensure the strength of the limiter pull plate 9, the limiter pull plate insert 9a is inlaid in the limiter pull plate 9 to ensure the service life of the limiter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com