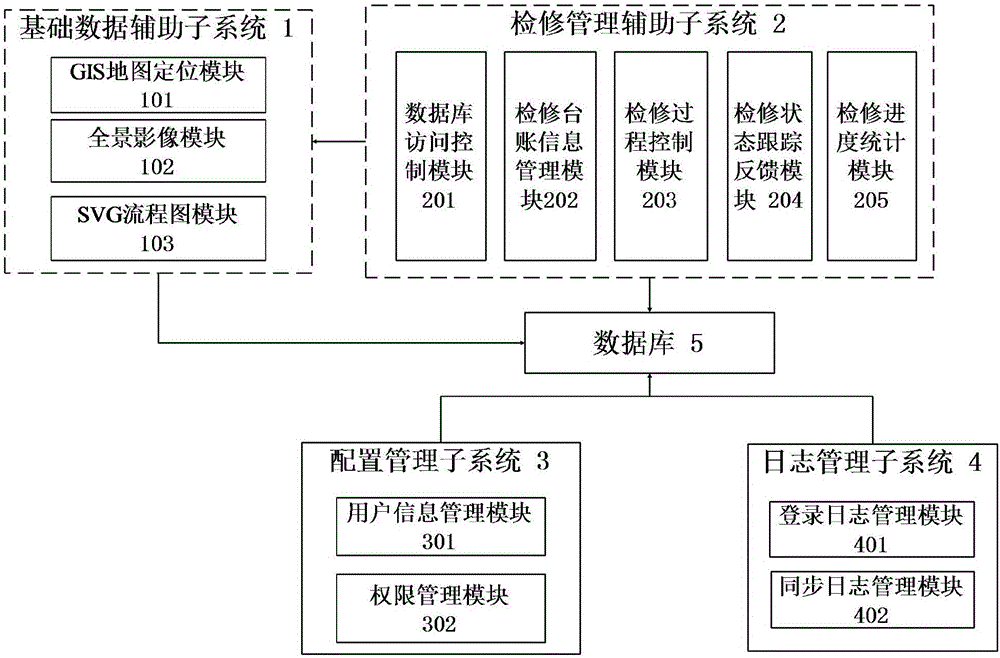

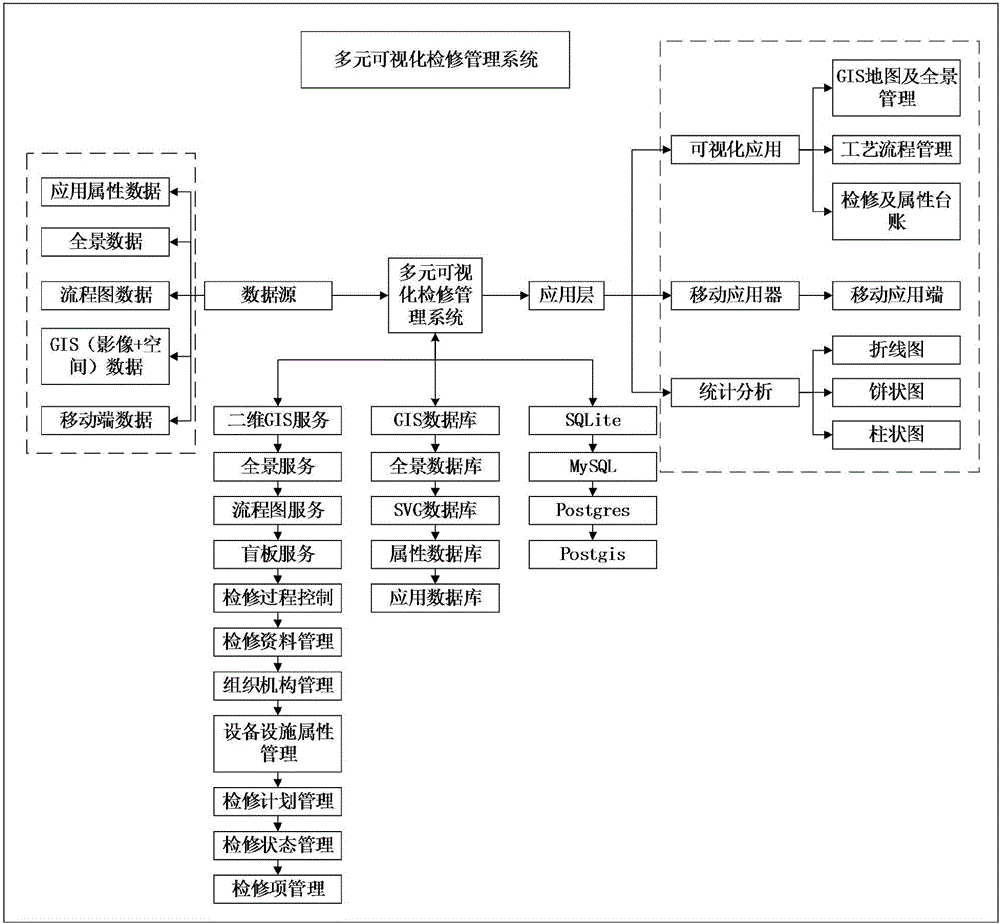

Multivariate visualization overhaul management system

A management system and multiple technologies, applied in the direction of instruments, etc., can solve problems such as inability to control working conditions, unfamiliarity with the site, and failure to find equipment and facilities for maintenance and site locations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

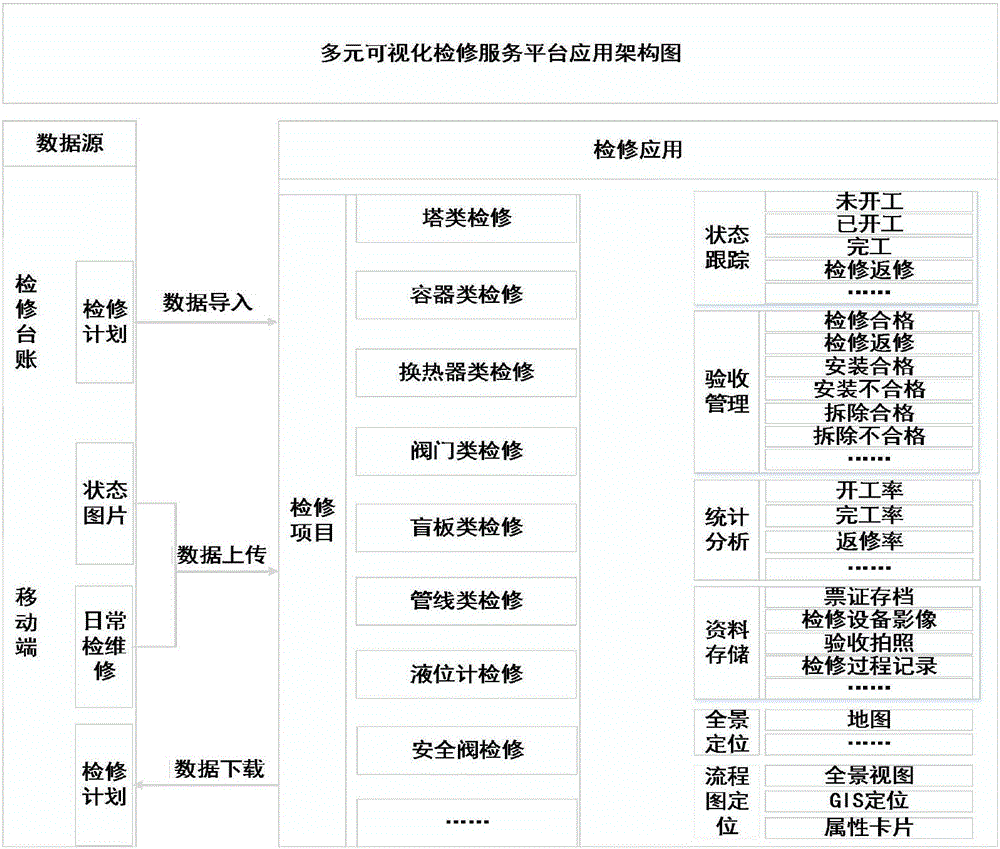

[0066] Such as image 3 As shown, the following is a preferred implementation of the above-mentioned solution of the present invention, the maintenance steps of the multiple visual maintenance management system are:

[0067] Step 1, importing the maintenance ledger information of the maintenance equipment, the SVG flowchart data, the panoramic image data and the GIS map data into the database 5 respectively;

[0068] Step 2, at the B / S end, access the database 5 through the multiple visual maintenance management system, and perform operations of checking, adding, deleting and editing the maintenance information;

[0069] Step 3, synchronously downloading the information in the database 5 to the mobile terminal;

[0070] Step 4, upload and synchronize the on-site maintenance data to the database 5 through the mobile terminal, and access the latest data information through the B / S terminal, wherein the on-site maintenance data on the mobile terminal includes maintenance status,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com