A precision assembly method for an eight-channel Kirkpatrick-Baez microscope

An assembly method and eight-channel technology, applied in the field of assembly of X-ray optical systems, can solve the problems of inability to correct, error correction and calibration, and no longer adjustable quantities, so as to achieve high assembly accuracy and avoid the problem of error introduction. Avoid the effects of harsh requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

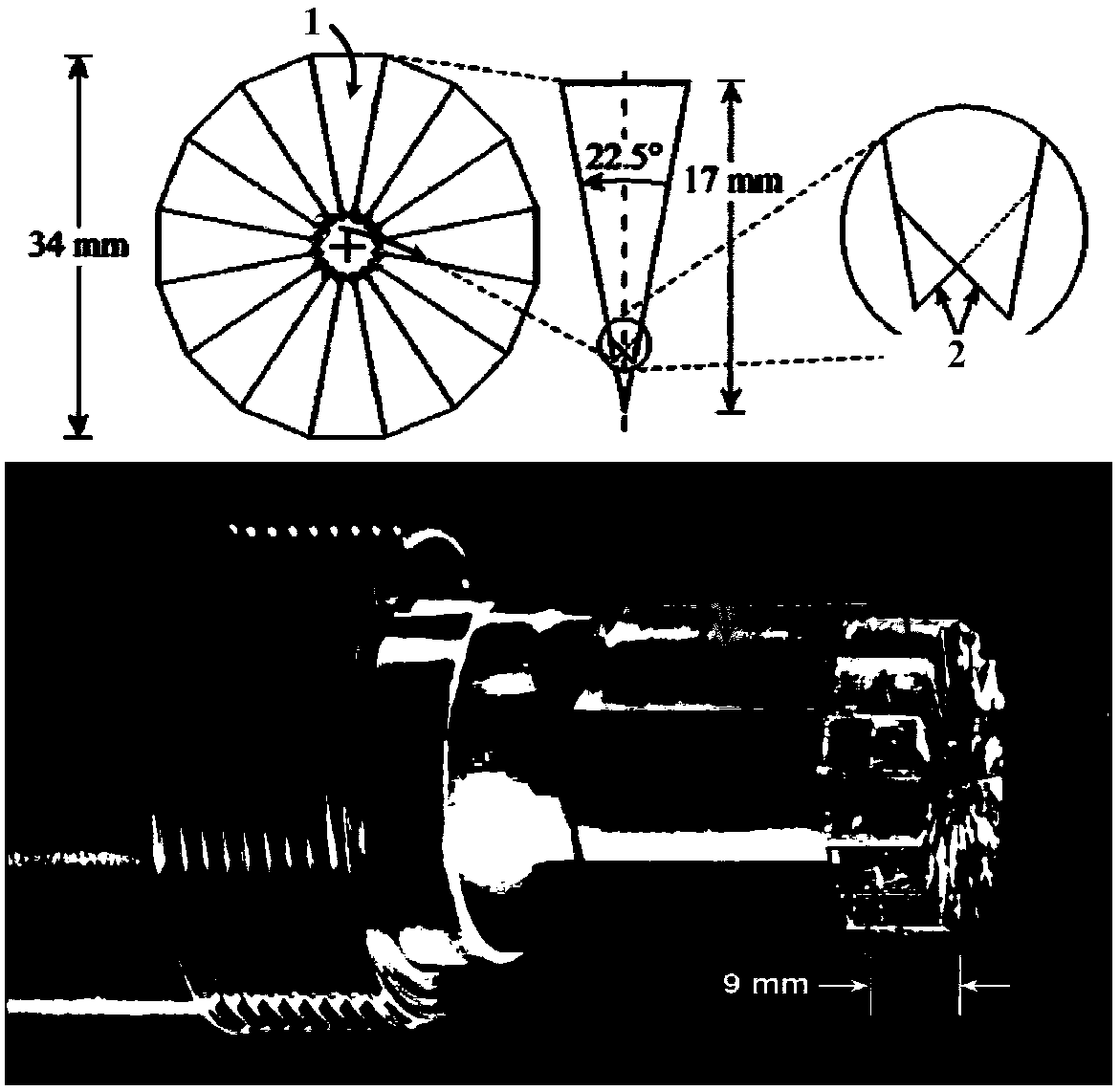

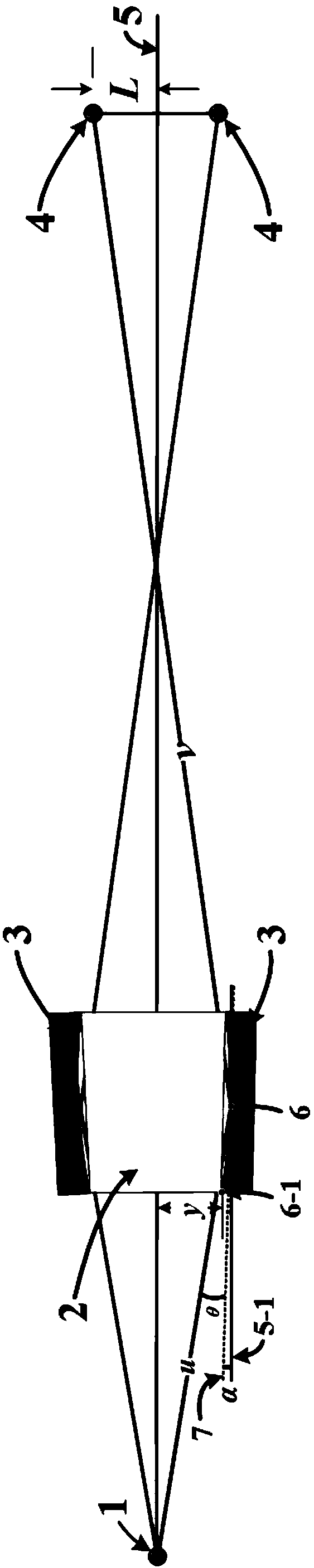

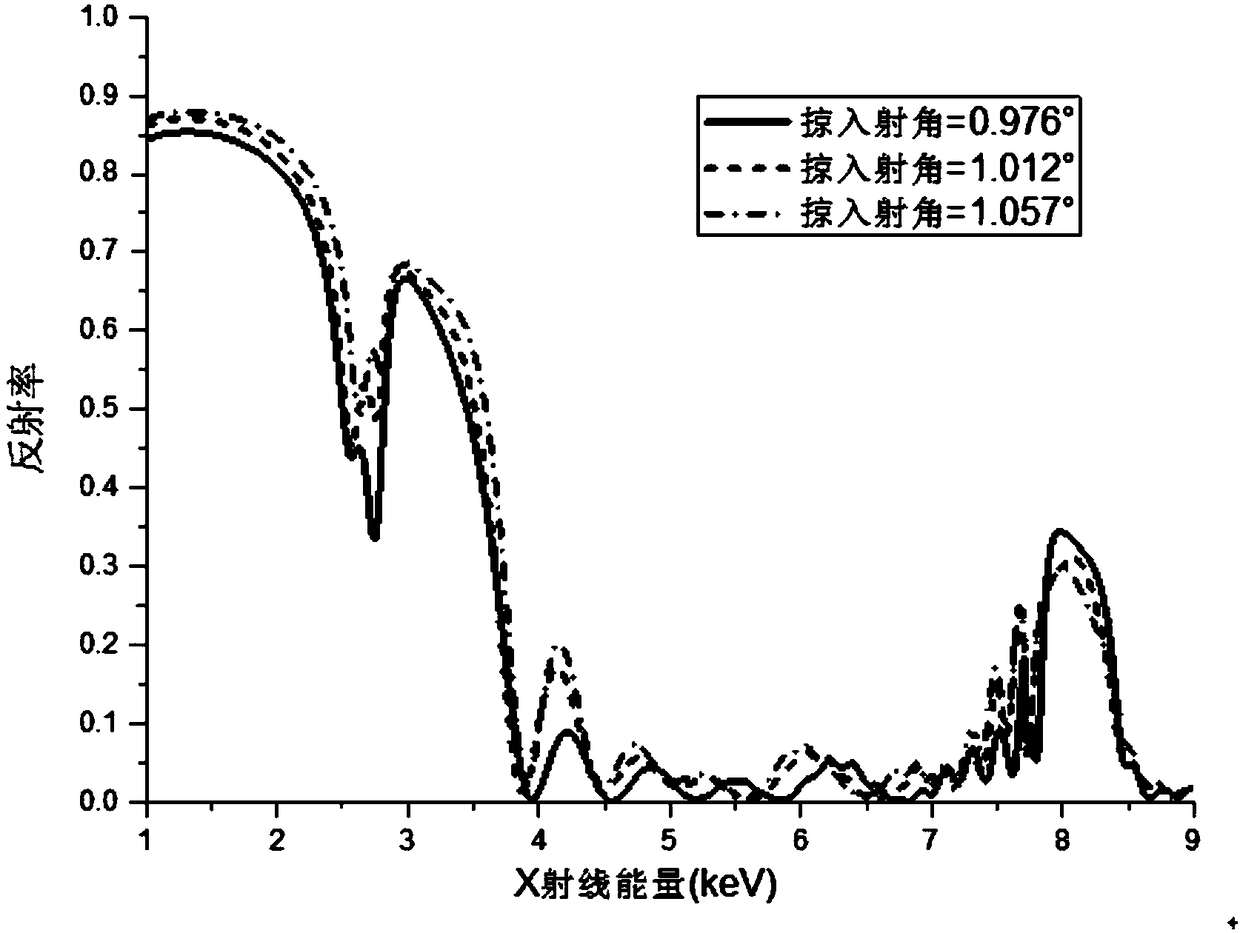

[0042] The objective lens will be used for the low-energy X-ray self-luminescence imaging diagnosis of the cone-shell target of the laser device during the implosion compression process or the Kα characteristic X-ray imaging diagnosis of the trace element Cu. This set of KB objective lenses is expected to be able to achieve imaging capabilities with a spatial resolution of about 5 microns for a target pellet with a diameter of about 500 microns. According to the application requirements of spatial resolution and light collection efficiency, the initial structural parameters of the eight-channel KB objective lens designed are shown in Table 1, where the radius of curvature of 20.5m is obtained through the actual measurement of the surface profiler (type Bruker ContourGT-X3). In order to reduce the deviation between the actual curvature radius and the design value in the optical cold processing process, thereby reducing the impact on the imaging of the KB objective lens. Table 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com