Light material wet sorting equipment

A light material, wet technology, applied in wet separation, solid separation, chemical instruments and methods, etc., can solve the problem of material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

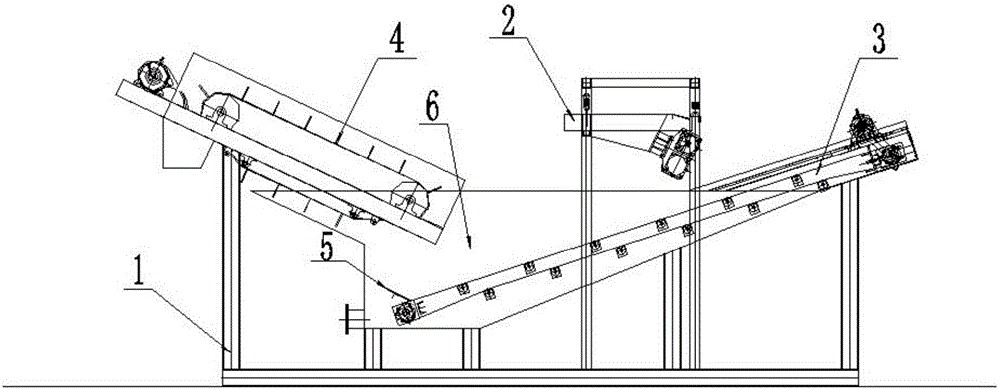

[0036] Such as figure 1 As shown, this embodiment provides a kind of light material wet sorting equipment, which is used to separate the light material and heavy material in the material, which includes a frame body 1, a feeder 2, a first transmission device 3, a second Two transmission devices 4, baffle plate 5 and water tank 6; the feeder 2 is arranged on the frame body 1, and the feeder 2 is located above the water tank 6 for conveying the material; The first conveying device 3 is arranged on the frame body 1 and is located below the feeder 2, the first conveying device 3 is arranged obliquely in its conveying direction, and in its conveying direction from low to The height is provided with a first end and a discharge end in turn, the first end of the first transmission device 3 is arranged under the water surface, and the discharge end of the first transmission device 3 is arranged higher than the water surface for Receiving heavy substances dropped into the water tank 6 ...

Embodiment 2

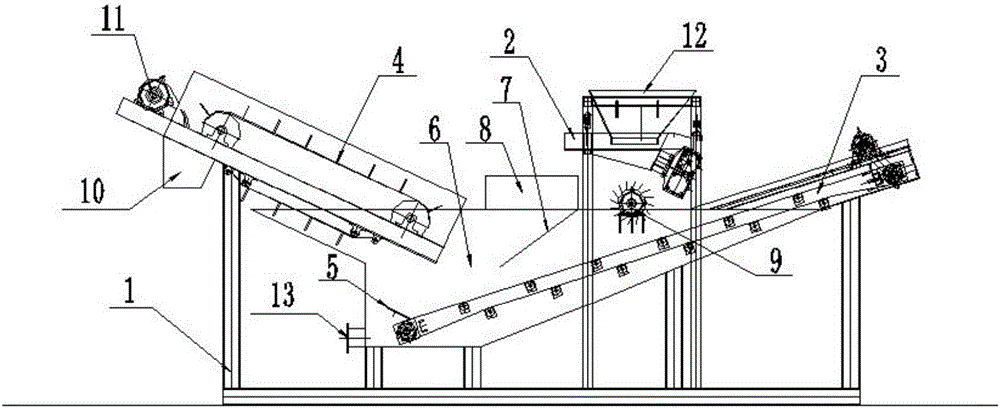

[0041] Such as figure 2As shown, the light material wet sorting equipment provided in this embodiment is used to separate the light material and heavy material in the material, and it includes a frame body 1, a feeder 2, a first transmission device 3, a second transmission device Device 4, baffle plate 5 and water tank 6; the feeder 2 is arranged on the frame body 1, and the feeder 2 is located above the water tank 6 for conveying the material; the first A conveying device 3 is arranged on the frame body 1 and located below the feeder 2, the first conveying device 3 is arranged obliquely in its conveying direction, and in its conveying direction from low to high A first end and a discharge end are provided, the first end of the first transmission device 3 is set under the water surface, and the discharge end of the first transmission device 3 is set higher than the water surface for receiving the fall into the heavy material in the water tank 6 and output the heavy material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com