Three-dimensionally shaped article and three-dimensionally shaping method

A three-dimensional modeling, single-layer technology, applied in the directions of additive manufacturing, transportation and packaging, process efficiency improvement, etc., can solve the problem of large-scale device cost and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

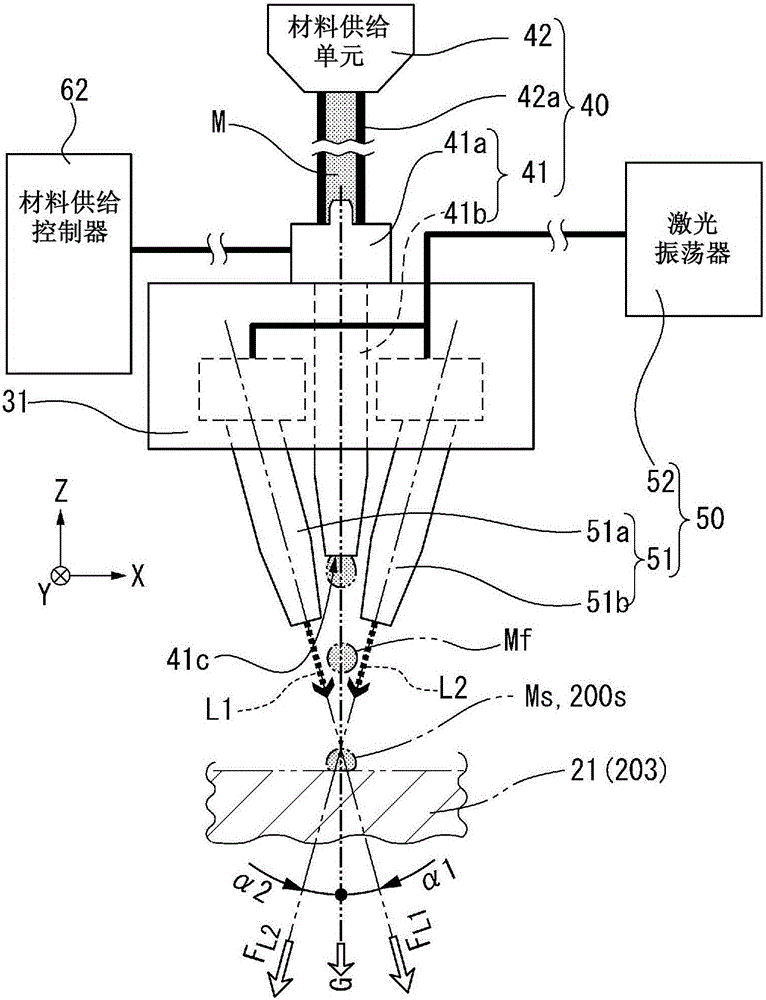

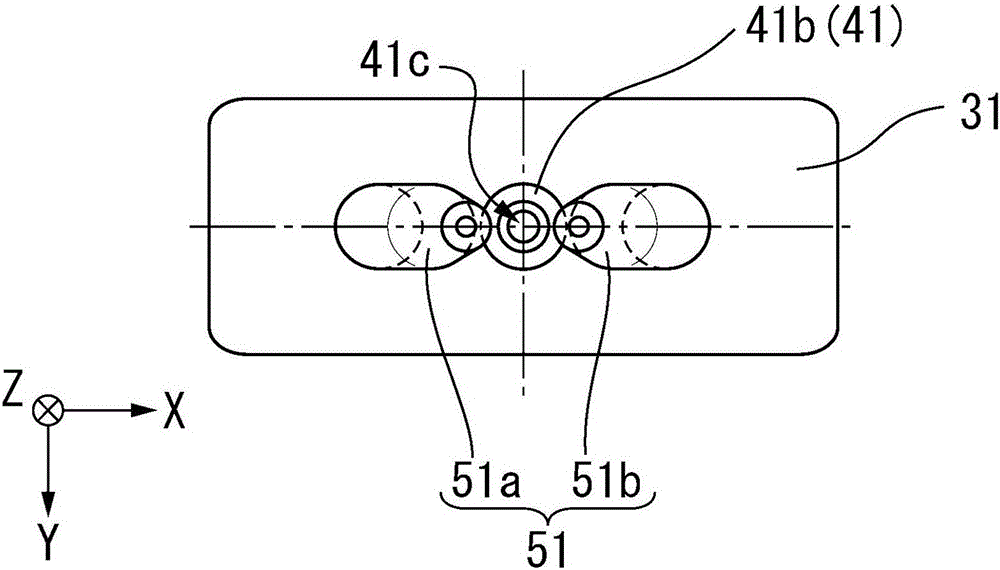

[0072] Hereinafter, embodiments according to the present invention will be described with reference to the drawings.

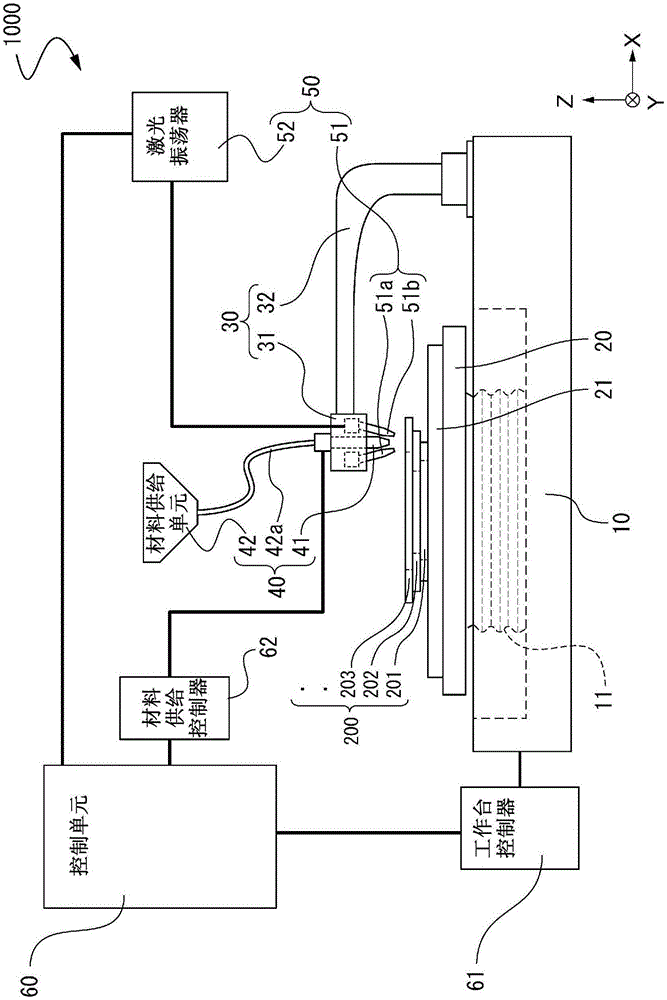

[0073] (first embodiment) figure 1 It is a schematic configuration diagram showing a schematic configuration of an example of a manufacturing apparatus for modeling a three-dimensional modeled object according to the first embodiment. It should be noted that the "three-dimensional shaped object" in this specification refers to an object formed into a so-called three-dimensional shaped object. For example, even a plate-shaped, so-called two-dimensional shaped object, as long as its shape has thickness in three-dimensional shapes.

[0074] Such as figure 1 As shown, the three-dimensional modeling apparatus 1000 includes: a base 10; a workbench 20 configured to be driven by the drive device 11 provided on the base 10 as a drive unit along the X, Y, and Z directions shown in the figure; and a head support The part 30 has one end fixed to the base 10, and the ot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com