Tin scraping mechanism

A technology of scraping tin and moving mechanism, which is applied in auxiliary devices, metal processing equipment, manufacturing tools, etc., can solve the problems of uneven tin scraping strength, hidden dangers, and reduce the effect of soldering, so as to avoid manual operation and ensure work safety. , Improve the effect of soldering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

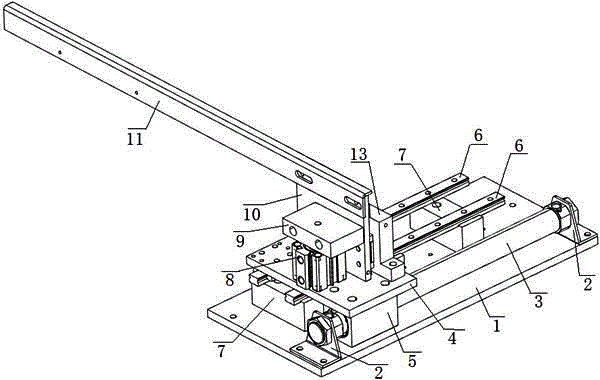

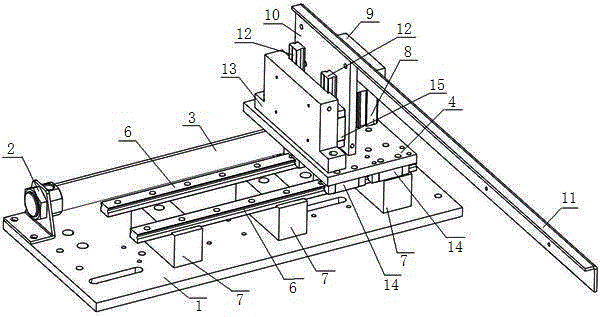

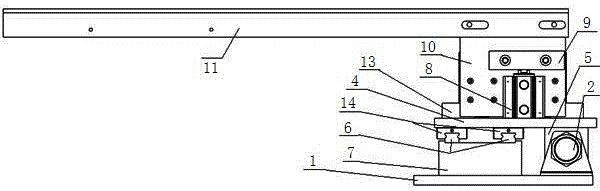

[0017] Such as Figure 1 to Figure 6 As shown, a tin scraping mechanism includes a fixed plate 1, a front and rear movement mechanism, an up and down movement mechanism and a tin scraper 11. Front and rear motion plates 4, front and rear cylinder connecting plates 5, front and rear guide rail bars 6, front and rear guide rail bar seats 7 and front and rear sliders 14, front and rear cylinder blocks 2 are fixed on the fixed plate 1, front and rear cylinder blocks 3 two ends are connected to front and rear cylinder blocks 2 and are formed by The front and rear cylinder bases 2 are fixed, the front and rear cylinder connecting plates 5 are connected to the ejector rods of the front and rear cylinders 3, the upper panels of the front and rear cylinder connecting plates 5 are connected and fixed to the front and rear movement plates 4, and the lower panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com