Suspension cushion

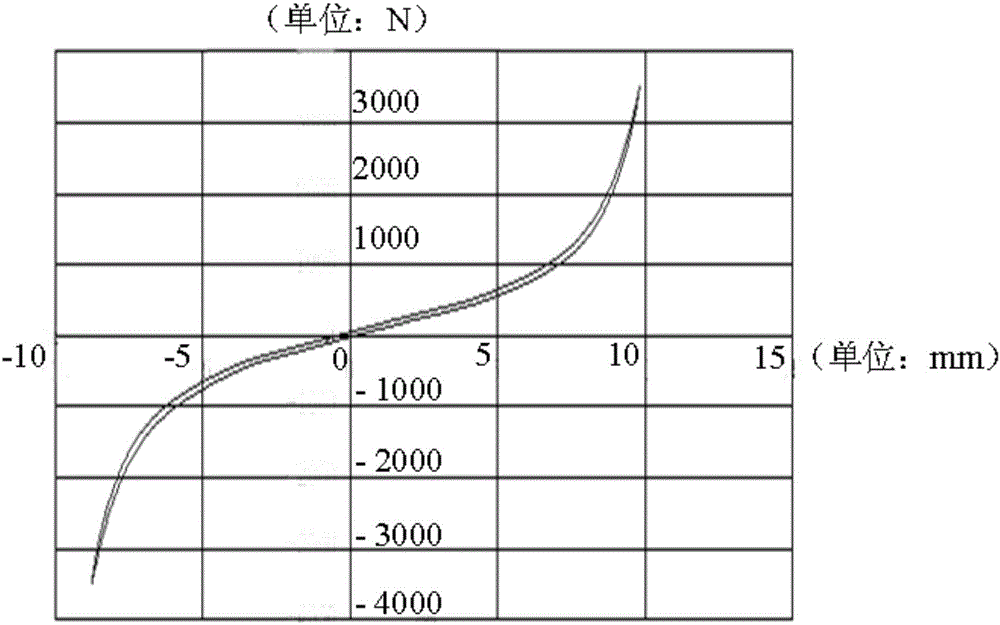

A technology for mounting soft pads and soft pads, which is applied in power units, jet propulsion units, internal combustion propulsion units, etc., can solve the problems affecting the noise level of the cab, the rise of the mount stiffness curve, and the shaking of the powertrain. Improve NVH performance, avoid sharp rise, smooth stiffness curve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

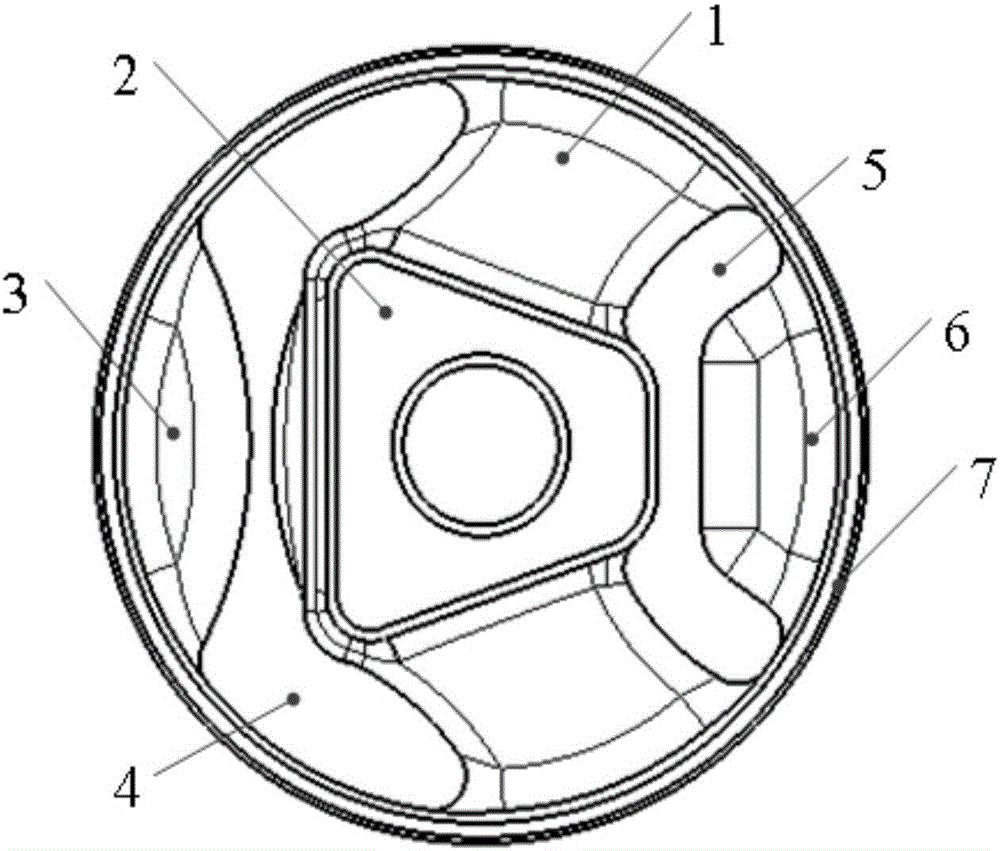

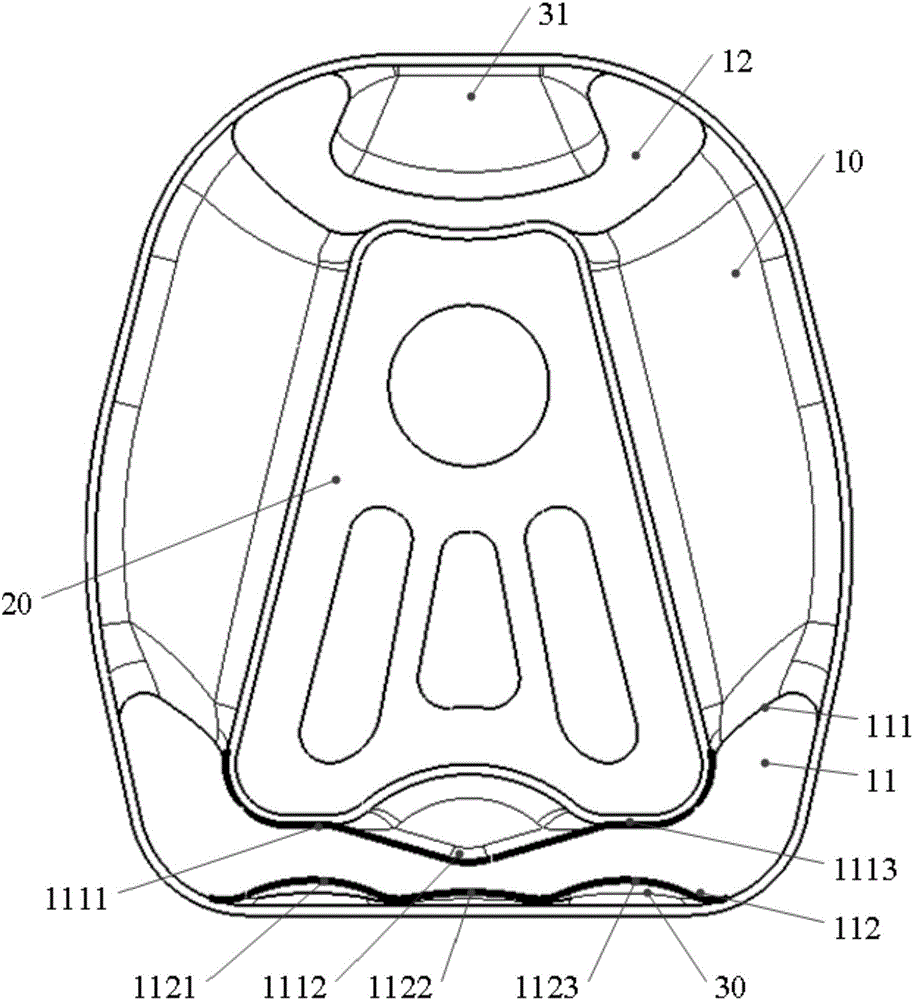

[0045] image 3 A schematic structural view of the suspension cushion provided by the embodiment of the present invention, such as image 3 As shown, the suspension cushion provided by the embodiment of the present invention includes a cushion body 10 and a suspension bracket 20 .

[0046] The cushion body 10 is symmetrically provided with a first cavity 11 and a second cavity 12 passing through the cushion body, the first cavity 11 is in the shape of a "concave", the second cavity 12 is a "trapezoid", and the "trapezoid" The bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com