Bottle cap preventing liquid overflowing from high-viscosity liquid storage bottle

A storage bottle, high-viscosity technology, applied in the direction of closure, packaging, transportation and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

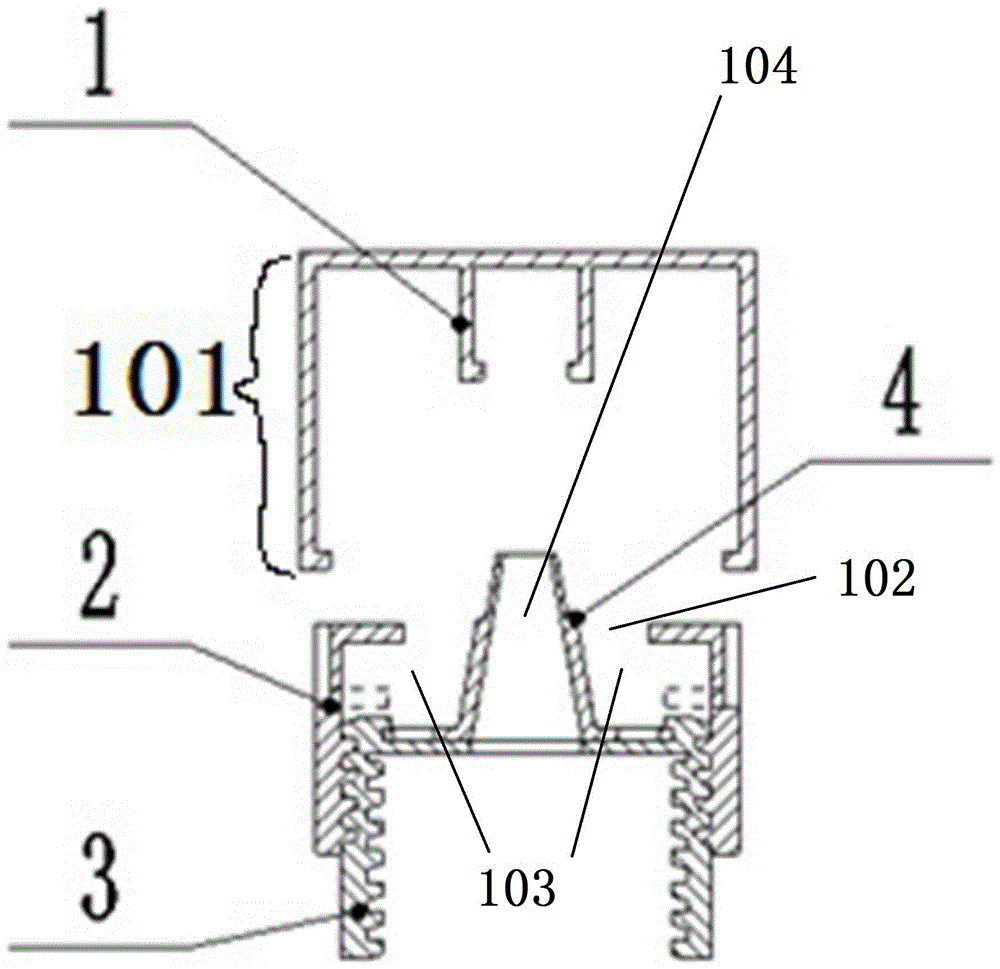

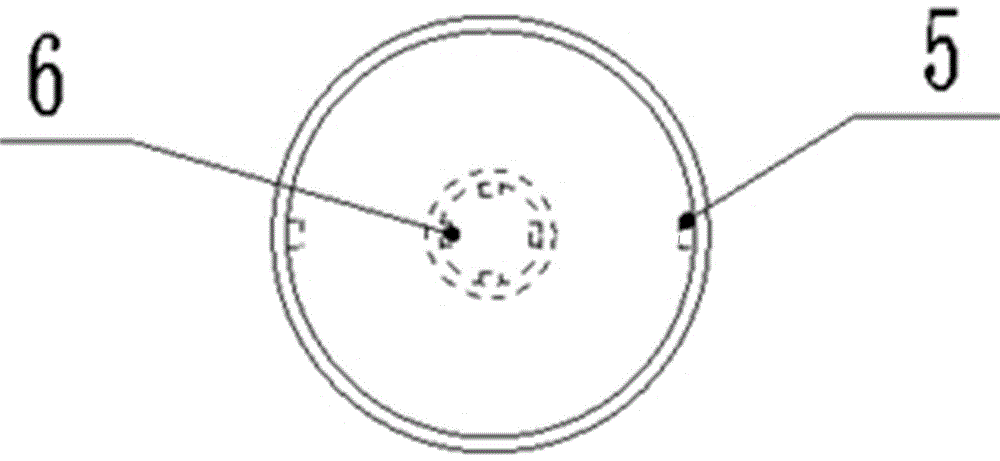

[0035] The user opens the upper screw cap, at this time the overflow return channel is half closed, the liquid in the bottle is poured out from the tip tube 4, and then the storage bottle is placed vertically, at this time, the liquid adhered to the mouth of the tip tube 4 flows out of the tip tube The pipe wall flows down to the overflow liquid temporary storage chamber 103 for temporary storage. When the liquid in the bottle is not needed again, the user covers the upper screw cap and tightens the upper screw cap. The ring bump 6 drives the tip tube to rotate, and the tip tube seat 105 rotates synchronously to make the overflow return channel formed by the tube seat hole 7 and the screw cap hole 14 conduct, and the overflow liquid temporarily stored in the overflow liquid temporary storage chamber 103 Return to the storage bottle through the overflow return channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com