Casting blast and pull shovel handling mining procedure

A technology of draglines and procedures, which is applied in the field of throwing and blasting dragline shovel mining procedures, can solve the problems of narrow working space of production equipment, large coal transportation distance, and short working line length, etc., so as to shorten the coal transportation distance and reduce the Production cost and effect of expanding work space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

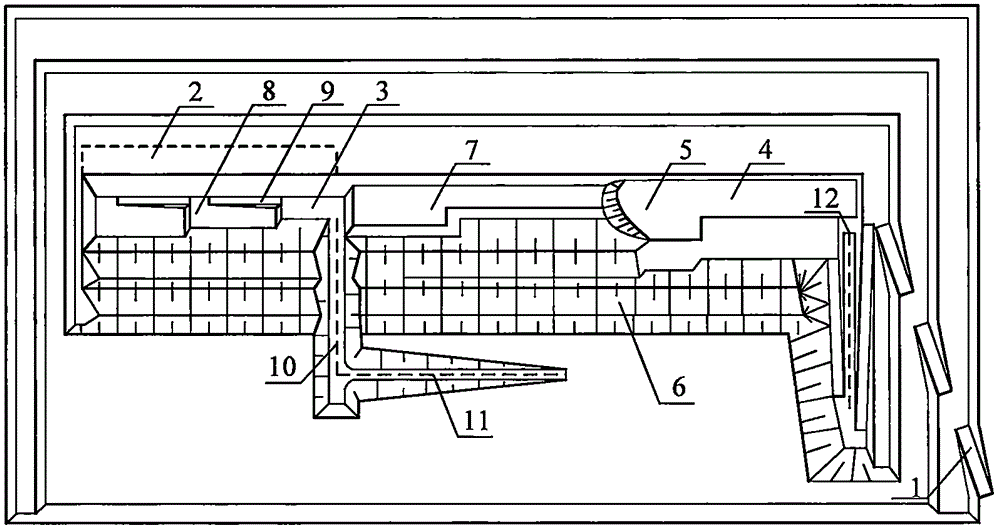

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] The throwing blasting drag bucket shoveling pile mining procedure of the present invention, the specific steps are as follows:

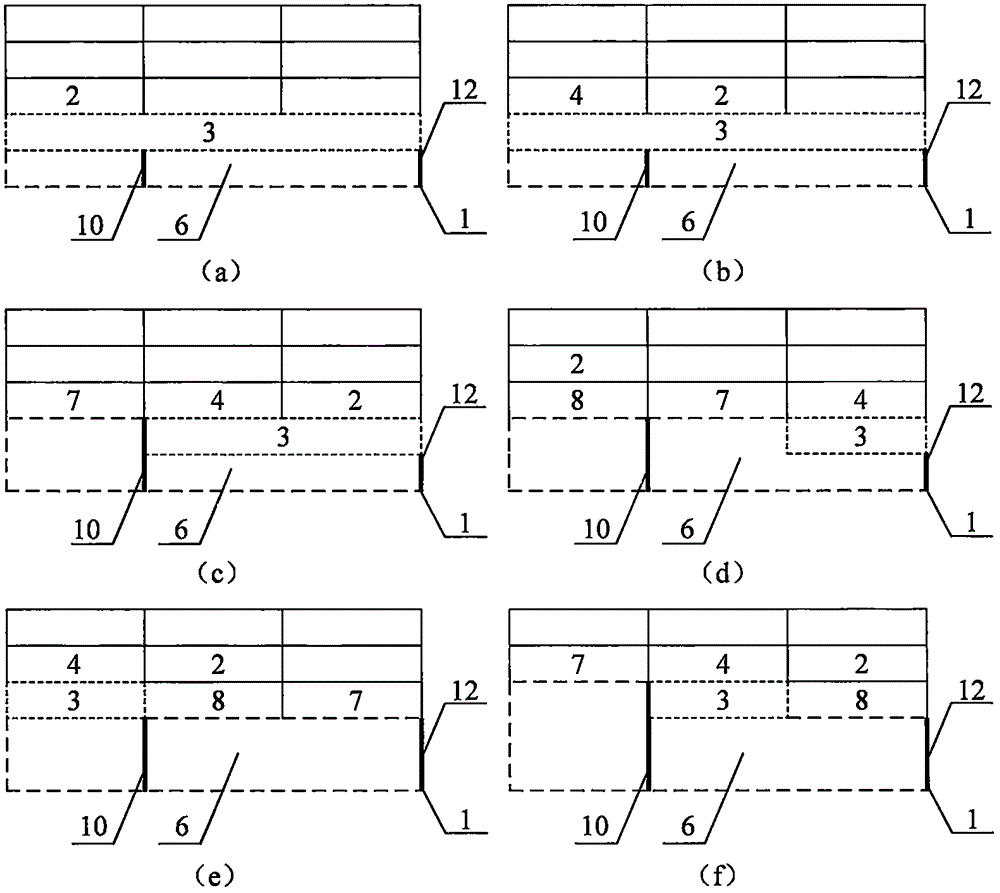

[0020] a. If figure 1 As shown in (a), the stope is divided into three areas on average along the layout direction of the working line. First, the area on the other side of the entrance and exit ditch 1 is set as the perforation and throwing blasting area 2, and the perforation, charge, connection, and detonation are carried out. Throw part of the stripping material to the gob 3 and form a pile explosion;

[0021] b. After the perforation and throwing blasting area 2 implements the throwing blasting, it becomes the drag bucket shoveling pile area 4, and the middle area becomes the perforation and throwing blasting area 2, such as figure 1 (b). In the dragline shoveling pile area 4, first use single-bucket excavators a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com