Diaphragm valve applicable to high-temperature and low-temperature environments

A diaphragm valve, high and low temperature technology, applied in the direction of diaphragm valve, diaphragm, valve device, etc., can solve the problems of poor sealing reliability, high temperature resistance, poor low temperature performance, etc., and achieve the effect of improving the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

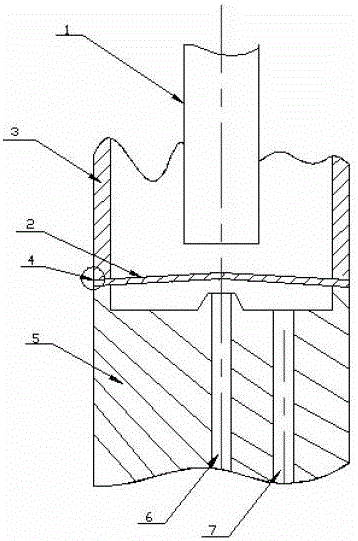

[0008] The structure of the diaphragm valve suitable for high and low temperature environment of the present invention is as follows: figure 1 As shown, it includes an upper valve body 3 and a lower valve body 5, the upper valve body 3 is provided with a valve stem 1, the lower part of the lower valve body 5 is provided with a fluid inlet 6 and a fluid outlet 7, and the valve plate 2 (diaphragm) is welded to the lower valve body 5.

[0009] In the invention, the diaphragm and the valve body are welded together, and a special metal material is used for brazing and sealing, so that the sealing type and reliability of the valve are significantly improved, and the temperature range of the operating environment can also be greatly improved.

[0010] The present invention has been described by means of embodiments, and those skilled in the art will appreciate that various changes or equivalent substitutions can be made to these features and embodiments without departing from the spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com