A Vibration Energy Harvester of S-shaped Piezoelectric Cantilever Beam

A vibration energy harvesting, cantilever beam technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. The miniaturization of the device and the reduction of the collected energy have achieved the effects of low processing cost, improved energy conversion efficiency, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The device of the present invention will be further described in detail below in conjunction with the accompanying drawings.

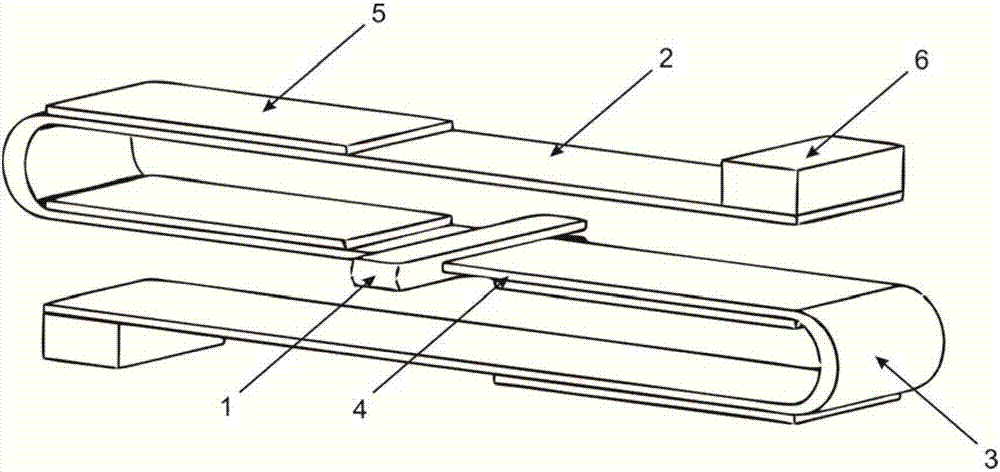

[0024] refer to figure 1 , An S-shaped piezoelectric cantilever beam vibration energy harvester disclosed in the present invention is composed of a support 1 , a free section 2 , a bending section 3 , a substrate section 4 , a piezoelectric element 5 , and a mass block 6 . An S-shaped cantilever beam mounted on the support is fixed on the support 1, and the S-shaped cantilever beam is composed of a substrate section 4, a curved section 3 and a free section 2; the surfaces of the substrate section 4 and the free section 2 are bonded The piezoelectric element 5 is glued; the end of the free section 2 is fixed with a quality block 6 .

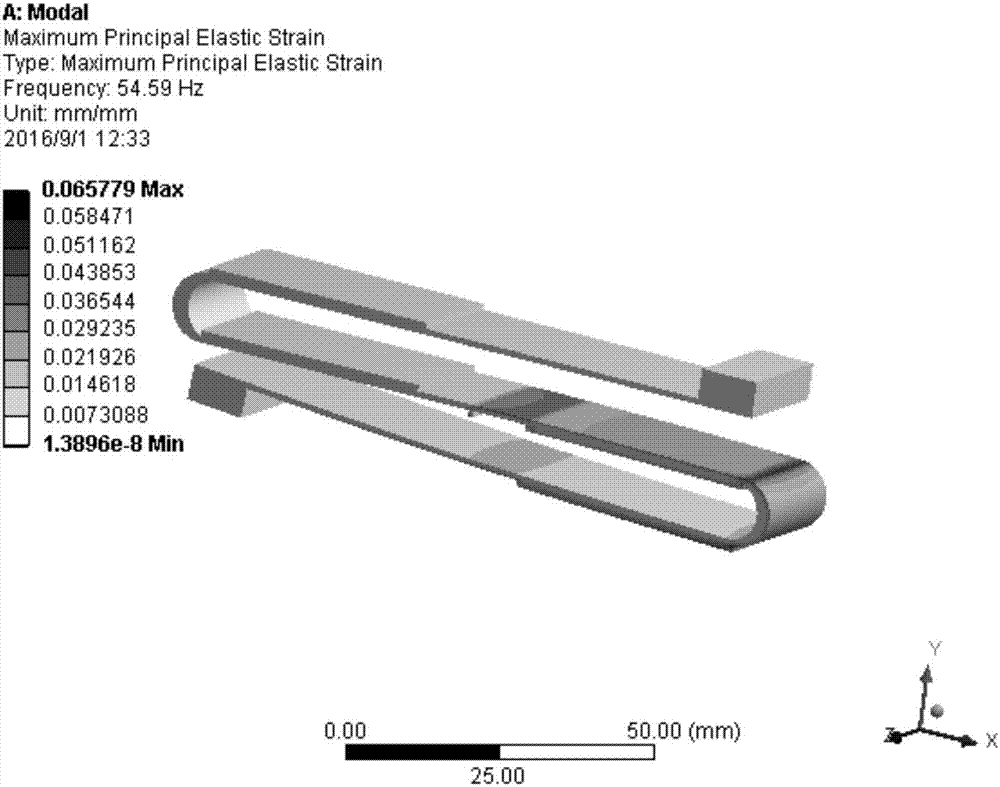

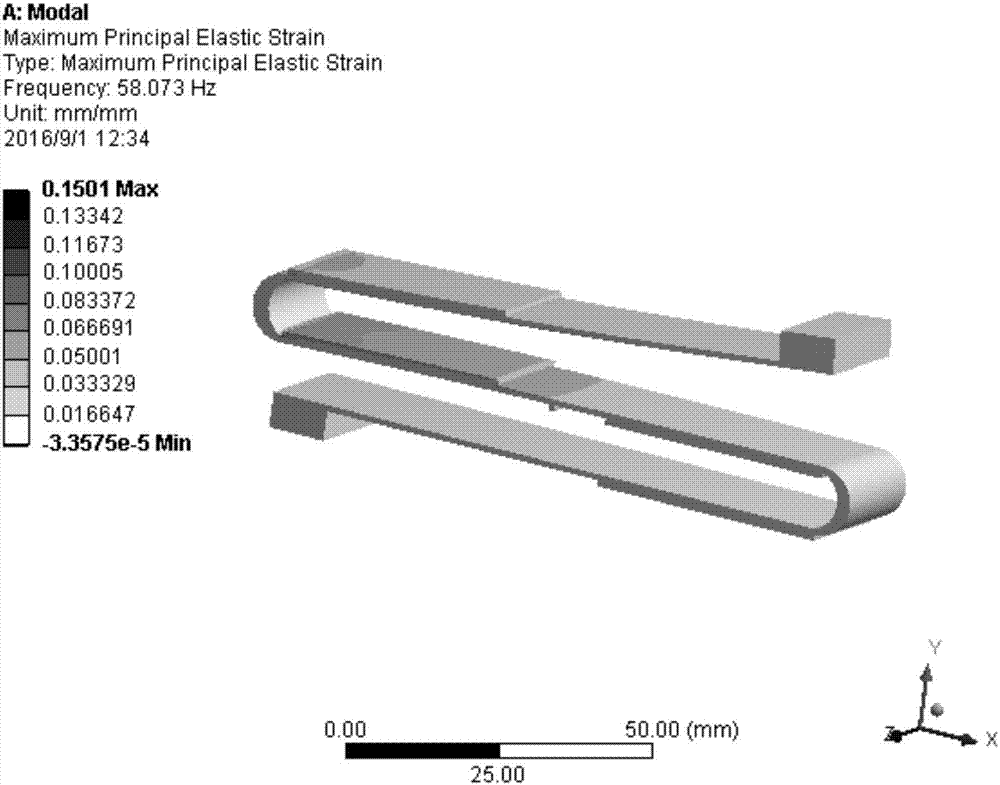

[0025] refer to figure 2 , image 3 , the first-order and second-order modal simulation diagrams are simulated under the environment of ANSYS workbench14.5, and the English in the attached drawings are automatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com