Ship bow beam and sailing ship with ship bow beam

A truss and bow technology, which is applied in the field of sailing boats to achieve the effects of simple operation, reduced risk factor, and safe movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

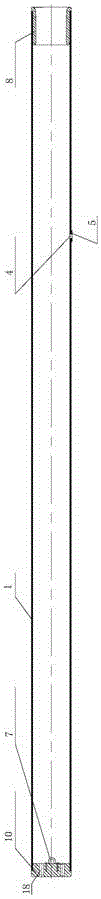

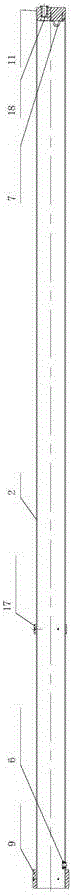

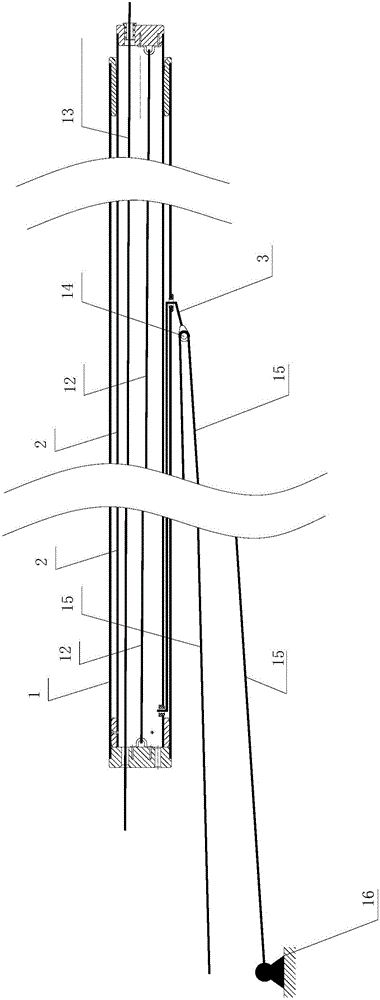

[0023] Figure 1 to Figure 4 It shows a specific embodiment of the bow girder of the present invention, the key improvement of which is that the bow girder is a telescopic structure with adjustable length, specifically, it includes an outer tube 1 and a telescopically movable insert An inner tube 2 arranged in the outer tube. Both the inner tube 2 and the outer tube 1 in this embodiment are aluminum alloy tubes.

[0024] In this embodiment, an inner tube stay cord 3 is fixedly connected to the inner tube 2, and a guide rope hole 4 is opened on the tube wall of the outer tube 1, and one end of the inner tube stay cord 3 passes through the The guide rope hole 4 protrudes from the outside of the outer tube 1 . In practical application, the user can drive the inner tube 2 to move forward in the outer tube 1 by pulling the inner tube pull rope 3, thereby extending the bow girder.

[0025] In order to prevent the inner tube stay rope 3 from directly rubbing against the aluminum a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com