Form book and its manufacturing method

A production method and form technology, applied in the direction of copying with carbon paper, adding non-fiber pulp, paper making, etc., can solve the problems of time-consuming and laborious, damage to triple copy paper sheets, etc., and achieve the effect of easy separation and accurate printing alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

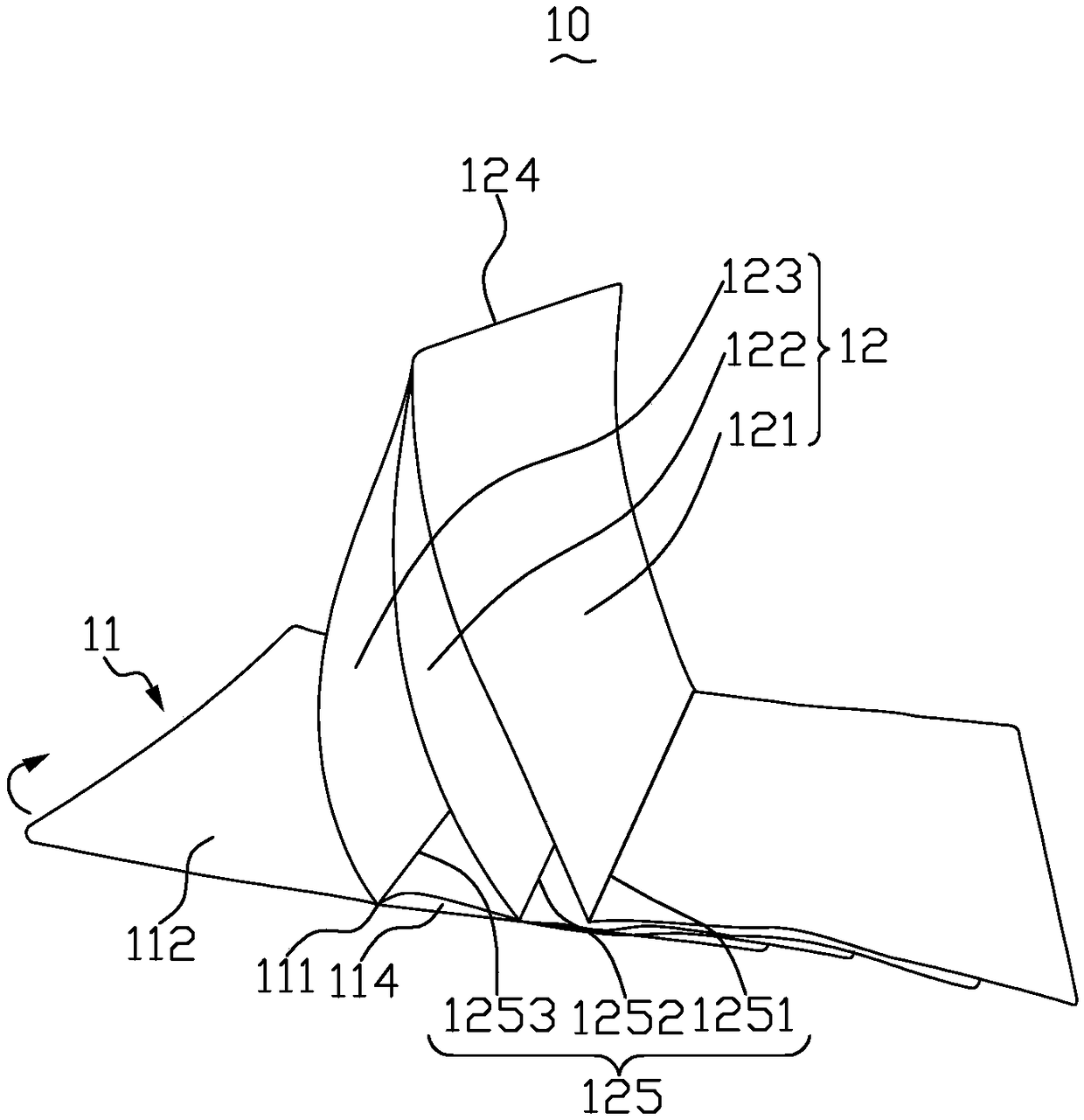

[0018] figure 1 It is a schematic structural diagram of the form book according to the embodiment of the present invention. For details, please refer to figure 1 , the form book 10 of the present invention includes a cover 11 and multipart copying paper 12 .

[0019] The cover 11 is a rectangular cardboard with a certain thickness and hardness. The middle part of the cover 11 has a cover crease 111 folded in half. The cover crease 111 makes the cover 11 divided into two symmetrical rectangular parts and the two symmetrical parts can be buckled together. Specifically Generally, the two symmetrical parts are the front cover 112 and the back cover 114. The outside of the front cover 112 is used to print the information of financial institutions a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com