Energy-saving coal saver

A technology of economizer and box, which is applied in the field of energy-saving economizer, and can solve the problems affecting the service life of equipment, the normal operation of the system, the low-temperature acid dew point corrosion of serpentine heat exchange tubes, the concentration of fly ash and the increase of flue gas flow rate, etc. , to achieve the effect of solving the problem of low temperature corrosion, low processing difficulty and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

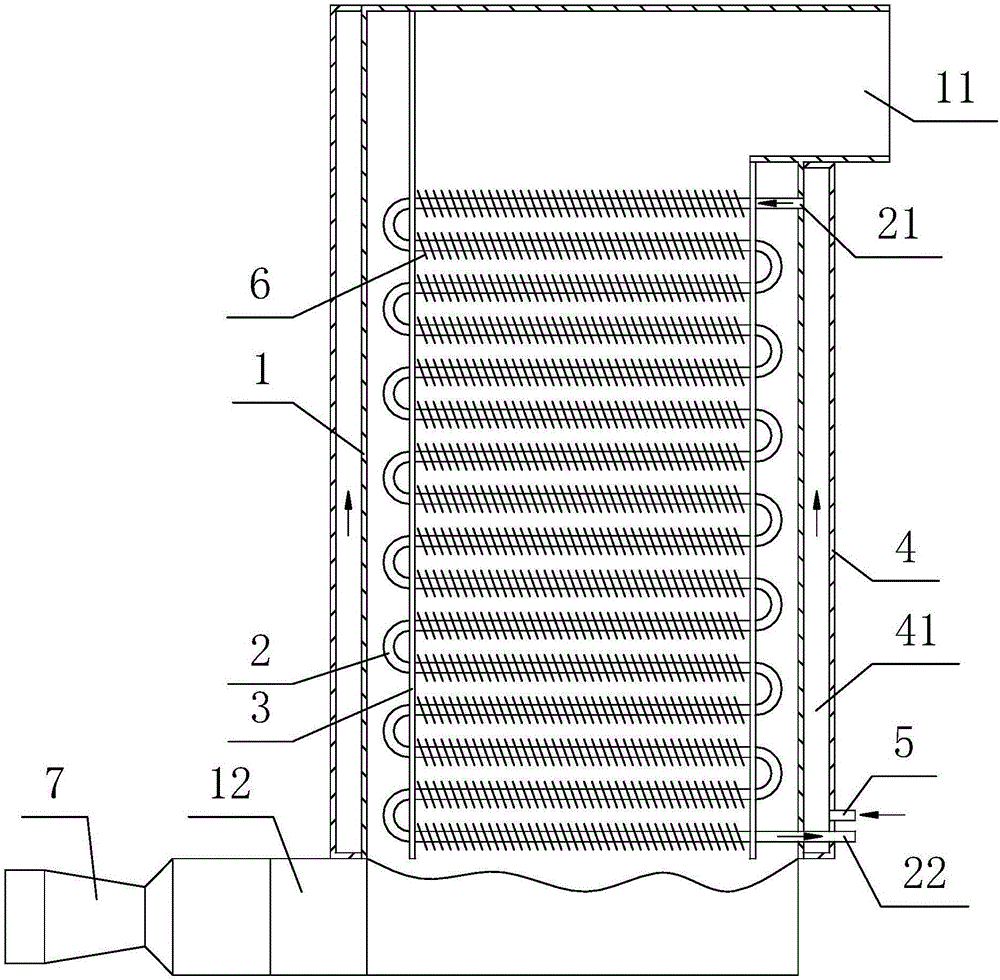

[0021] Such as figure 1 As shown, an energy-saving economizer includes a box body 1 and a serpentine heat exchange tube 2. The top and bottom of the box body 1 are closed, and a horizontal inlet is provided at the junction of the side wall and the top of the box body 1. The smoke inlet 11 of the smoke, the side wall and the bottom of the box body 1 are provided with a horizontal smoke outlet 12, and the smoke outlet 12 is connected with a Venturi tube 7, and the Venturi tube 7 makes The flue gas flow changes from thick to thin, so that the flue gas forms a "vacuum" area on the rear side of the outlet of the Venturi tube 7. The adsorption effect generated by this vacuum area accelerates the flow rate of the flue gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com