Assembly device for electromagnetic coil

An electromagnetic coil and assembly device technology, which is applied in coil manufacturing, metal processing, metal processing equipment, etc., can solve the problem that the direction of magnetic core transportation is not easy to ensure the magnetic core, and achieve the effect of improving assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

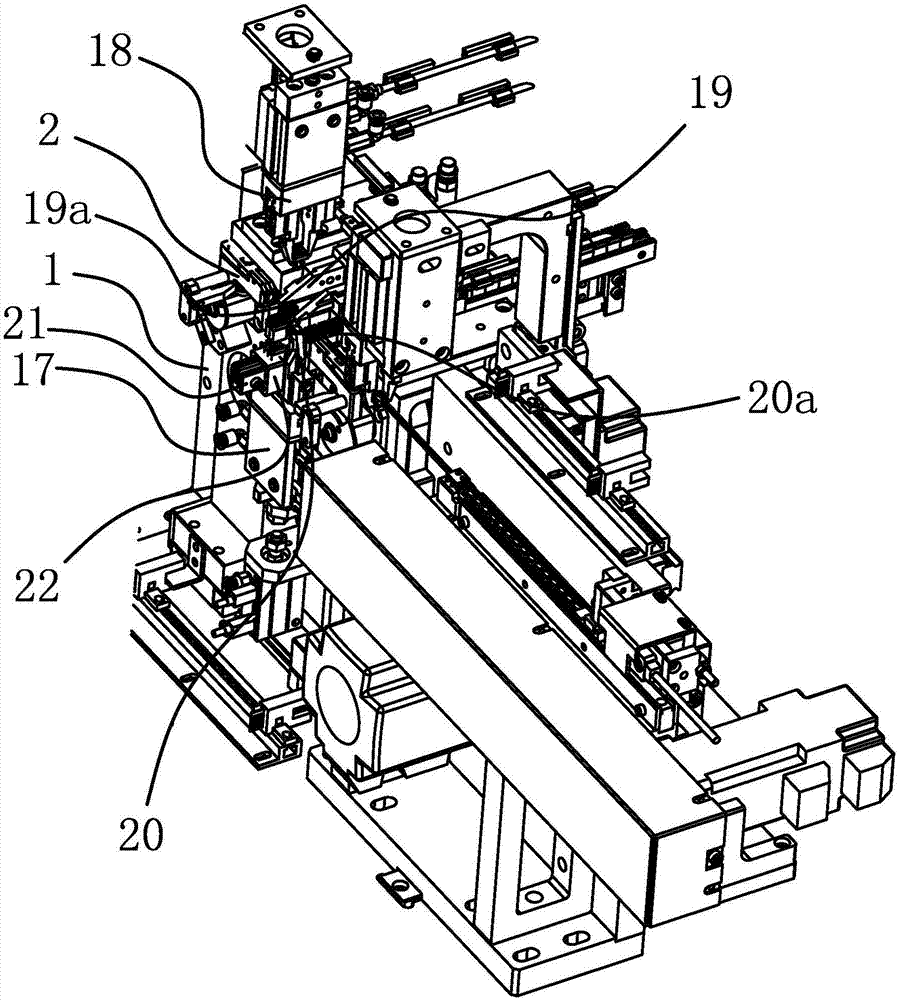

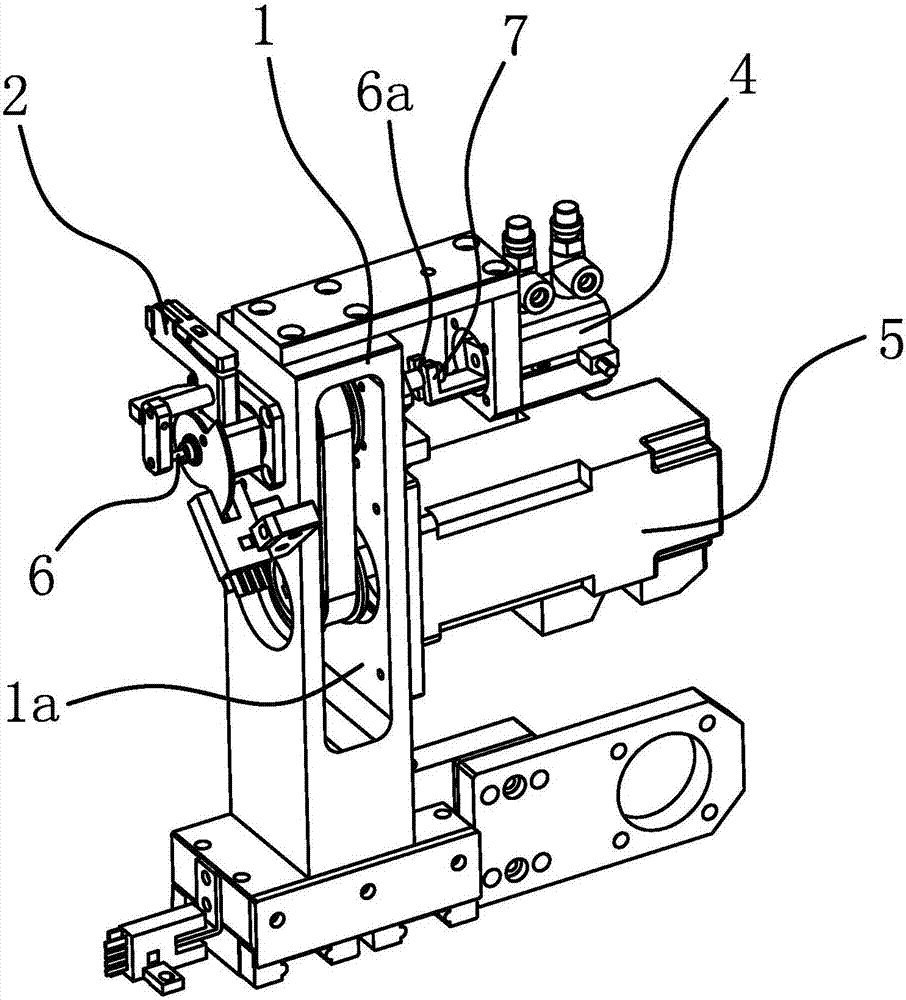

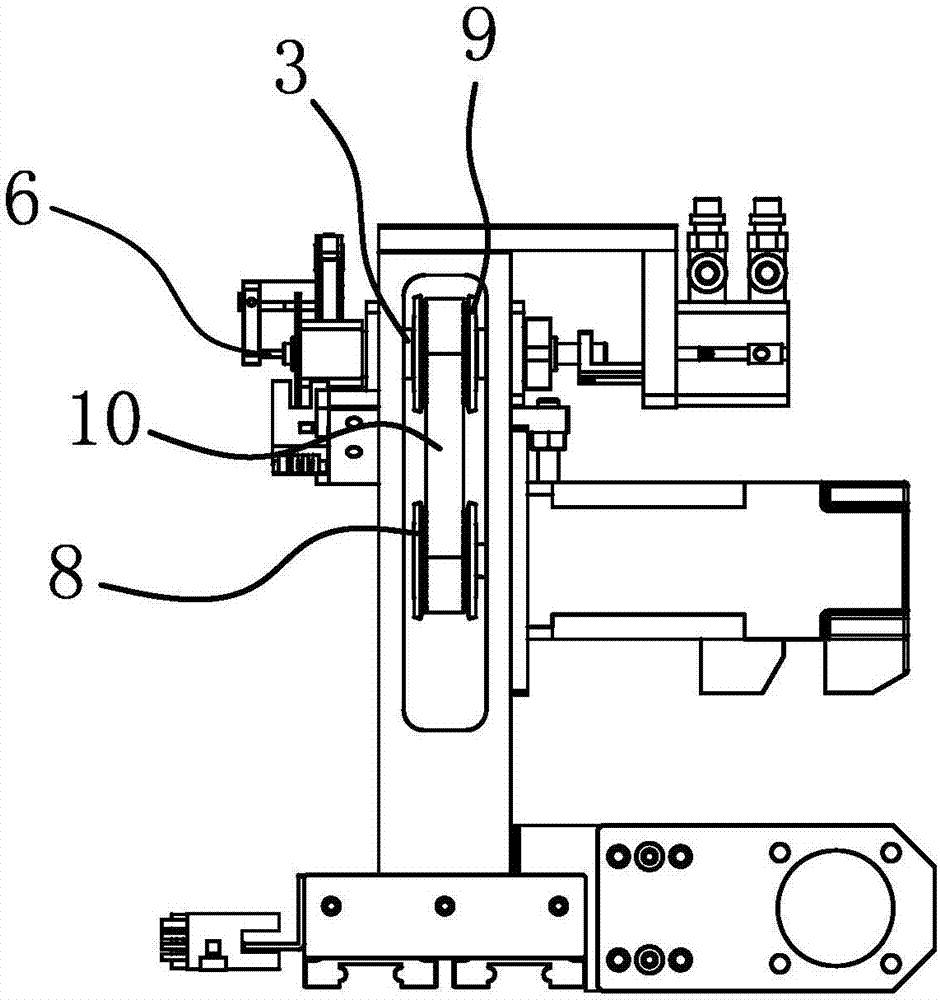

[0035] like figure 1 As shown, the assembly device of the electromagnetic coil includes a support 17, the support 17 is connected with a manipulator 18 for clamping the coil, and also includes two frames 1, and the above two frames 1 are connected on the left and right sides of the support 17 At both sides, the frame 1 is connected with clamping parts 2 capable of clamping the magnetic core, and the two clamping parts 2 are symmetrically arranged on both sides of the bracket 17 based on the bracket 17, and the bracket 17 is composed of From top to bottom, a preliminary assembly 19, a final assembly 20, and a discharge channel 21 are also provided. The above-mentioned manipulator 18 and the gripper 2 can respectively transport the coil and the magnetic core to the initial assembly 19 for initial assembly. The above-mentioned final assembly After the part 20 is moved up, the electromagnetic coil formed by the initial assembly can be clamped and secondarily compressed and assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com