Soaking solution for preparing anti-mold sheet, anti-mold sheet and preparation method thereof

A soaking solution and anti-mildew technology, which is applied in the fields of application, food science, food preservation, etc., can solve problems such as adverse effects on human health, affecting food taste, and potential safety hazards, and achieves shortening soaking time, strengthening moisture absorption, and good moisture absorption. anti-mold effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A kind of mildew-proof sheet of the present embodiment is prepared by the following method:

[0044] (1) Add glucose into water, stir until completely dissolved, quickly add glucose oxidase, stir evenly, add ethanol, stir evenly, and obtain liquid A;

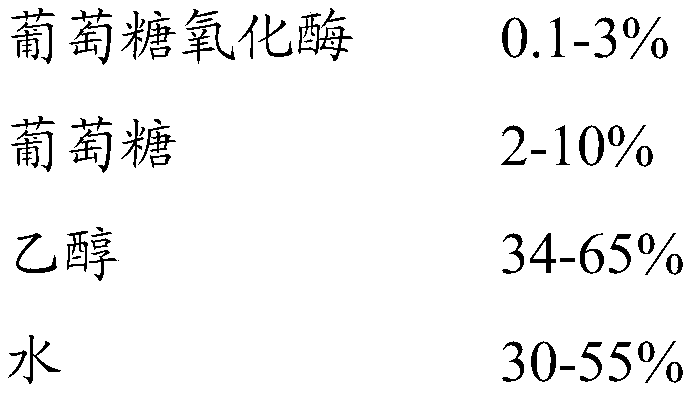

[0045] The weight percent of each component in the gained A liquid is:

[0046]

[0047] (2) adding essence into ethanol, stirring evenly to obtain liquid B; the essence content in the obtained liquid B is 0.55wt%.

[0048] (3) Put the absorbent paper (adsorptive paper) in the No. 1 container filled with liquid A and soak for 20 minutes (the soaking container is sealed, the pressure is 0.1mpa, and the temperature is 18°C); take out the absorbent paper, Then put it in the No. 2 container with B liquid and soak for 30 minutes (the soaking container is airtight, the pressure is 0.15mpa, and the temperature is 18°C); Centrifuge for 1 minute;

[0049] (4) Decompression, sub-package, and that's it.

Embodiment 2

[0051] A kind of mildew-proof sheet of the present embodiment is prepared by the following method:

[0052] (1) Add glucose into water, stir until completely dissolved, quickly add glucose oxidase, stir evenly, add ethanol, stir evenly, and obtain liquid A;

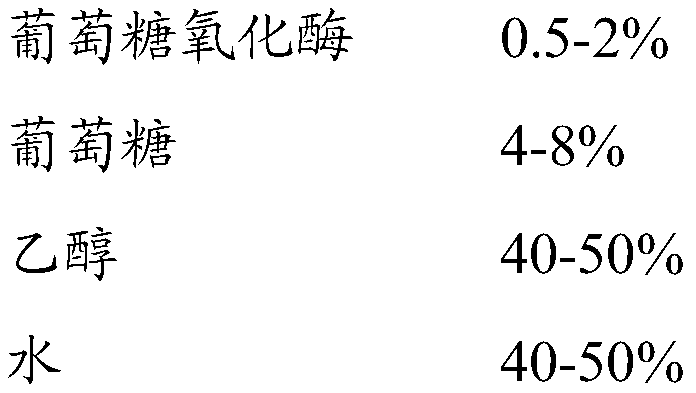

[0053] The weight percent of each component in the gained A liquid is:

[0054]

[0055] (2) adding the essence into ethanol, stirring evenly to obtain liquid B; the essence content in the obtained liquid B is 0.1 wt%.

[0056] (3) Soak the absorbent paper in the No. 1 container containing liquid A for 20 minutes (the soaking container is sealed, the pressure is 0.1mpa, and the temperature is 18°C); take out the absorbent paper, and then place it in the container containing B Soak in the No. 2 container of liquid for 25 minutes (the soaking container is sealed, the pressure is 0.15mpa, and the temperature is 18°C); take out the soaked absorbent paper, and then centrifuge it at a speed of 100rpm for 1 minute;

[0057]...

Embodiment 3

[0059] A kind of mildew-proof sheet of the present embodiment is prepared by the following method:

[0060] (1) Add glucose into water, stir until completely dissolved, quickly add glucose oxidase, stir evenly, add ethanol, stir evenly, and obtain liquid A;

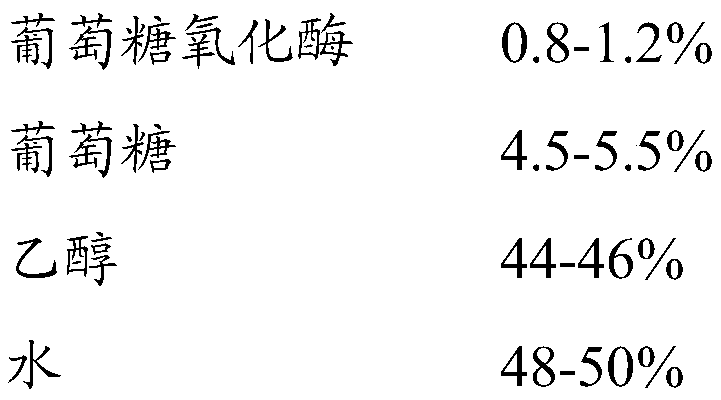

[0061] The weight percent of each component in the gained A liquid is:

[0062]

[0063] (2) adding the essence into ethanol, stirring evenly to obtain liquid B; the essence content in the obtained liquid B is 2 wt%.

[0064] (3) Soak the absorbent paper in the No. 1 container containing liquid A for 25 minutes (the soaking container is sealed, the pressure is 0.1mpa, and the temperature is 18°C); take out the absorbent paper, and then place it in the container containing B Soak in the No. 2 container of liquid for 35 minutes (the soaking container is sealed, the pressure is 0.15mpa, and the temperature is 18°C); take out the soaked absorbent paper, and then centrifuge it at a speed of 100rpm for 1 minute;

[0065] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com