Novel mesh-shaped roller peeler

A mesh drum and peeling machine technology, applied in the peeling of vegetables or fruits, food science, application, etc., can solve the problems of low peeling efficiency, small friction, poor effect, etc., achieve good peeling effect and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is specifically described below in conjunction with accompanying drawing and embodiment:

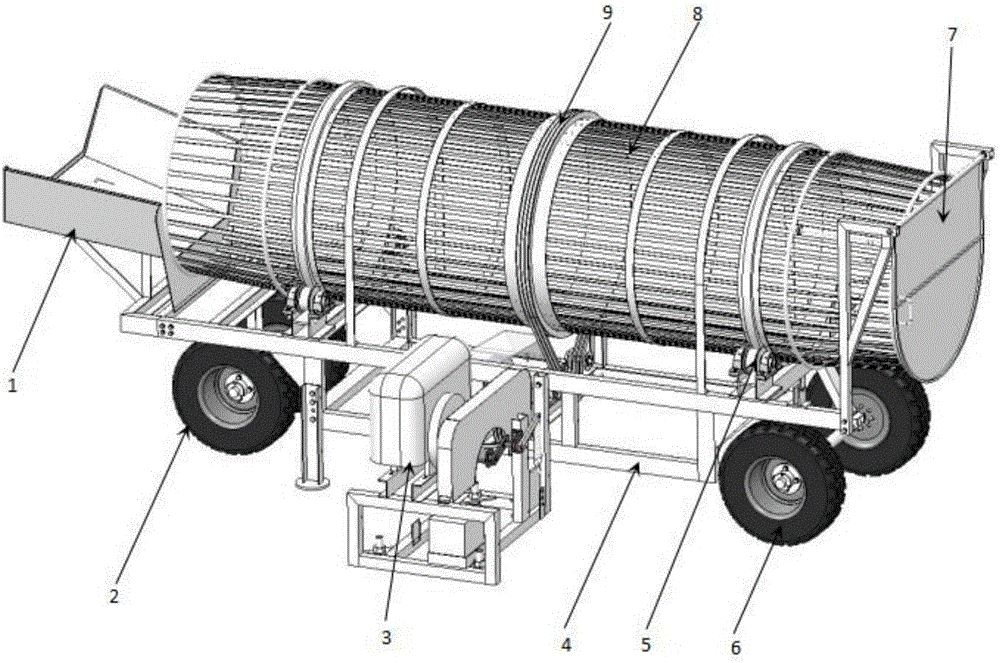

[0015] The power is provided by the diesel engine frame assembly 3, the power is transmitted through the B-shaped V-belt 9, and the peeling roller cage assembly 8 is driven to rotate through the deceleration of the pulley. The idler 5 plays the role of supporting the peeling roller cage assembly 8. The role of supporting the peeling machine components, the front wheel train 6 and the rear wheel train 2 components are mainly used for equipment movement.

[0016] Before starting, the peeling baffle 7 is closed, and the diesel engine frame assembly 3 is started, and cassava enters the peeling rolling cage assembly 8 by the lower hopper 1. After the cassava peeling process is completed, the peeling baffle 7 is opened, and the cassava is discharged by the peeling rolling cage assembly 8.

[0017] The above is only a preferred embodiment of the present invention, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com