Novel net-shaped roller peeling machine

A mesh drum and peeling machine technology, which is applied in the fields of vegetable or fruit peeling, food science, application, etc., can solve the problems of low peeling efficiency, low friction, poor effect, etc., and achieve good peeling effect and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

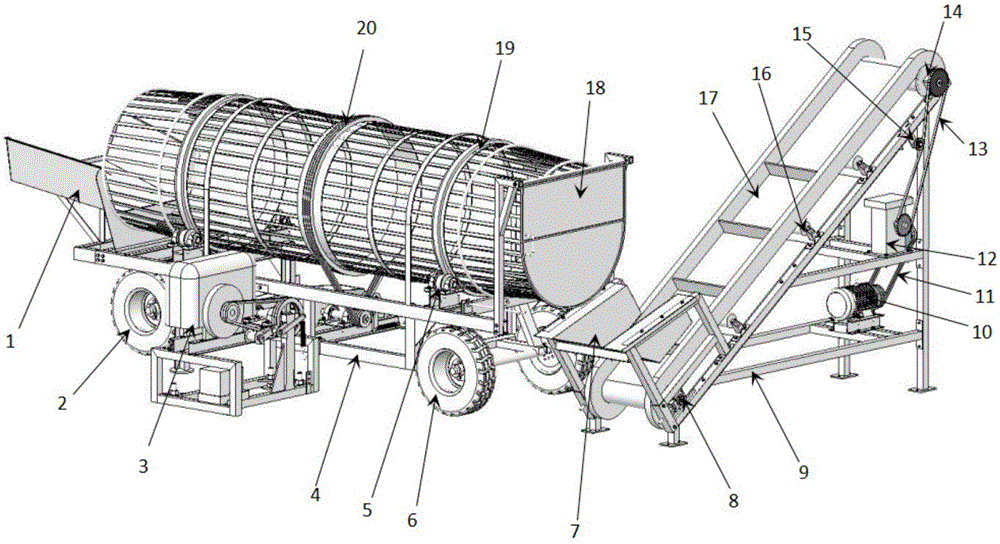

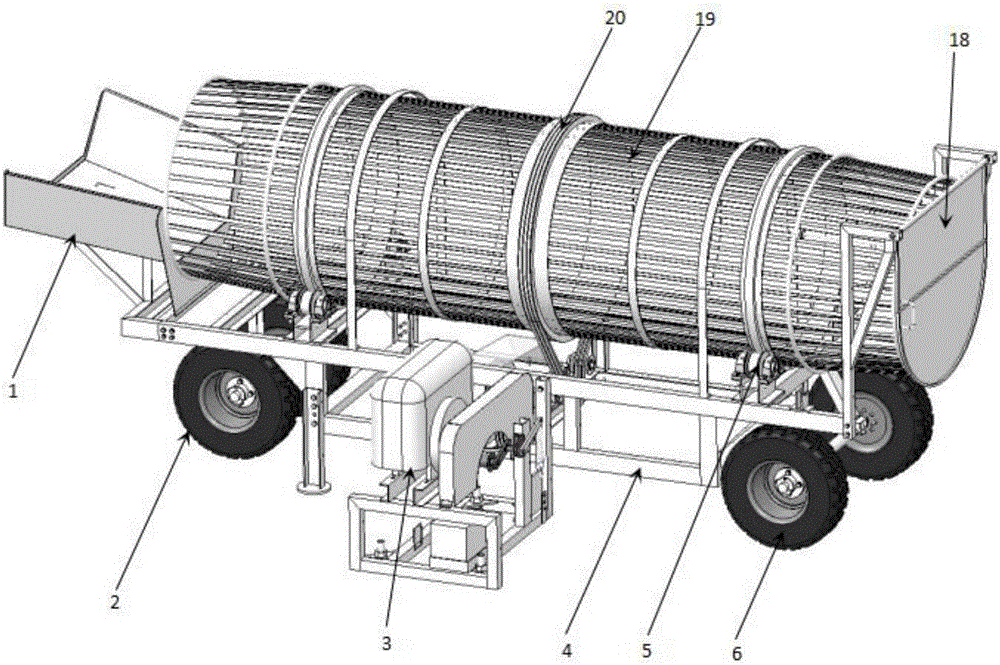

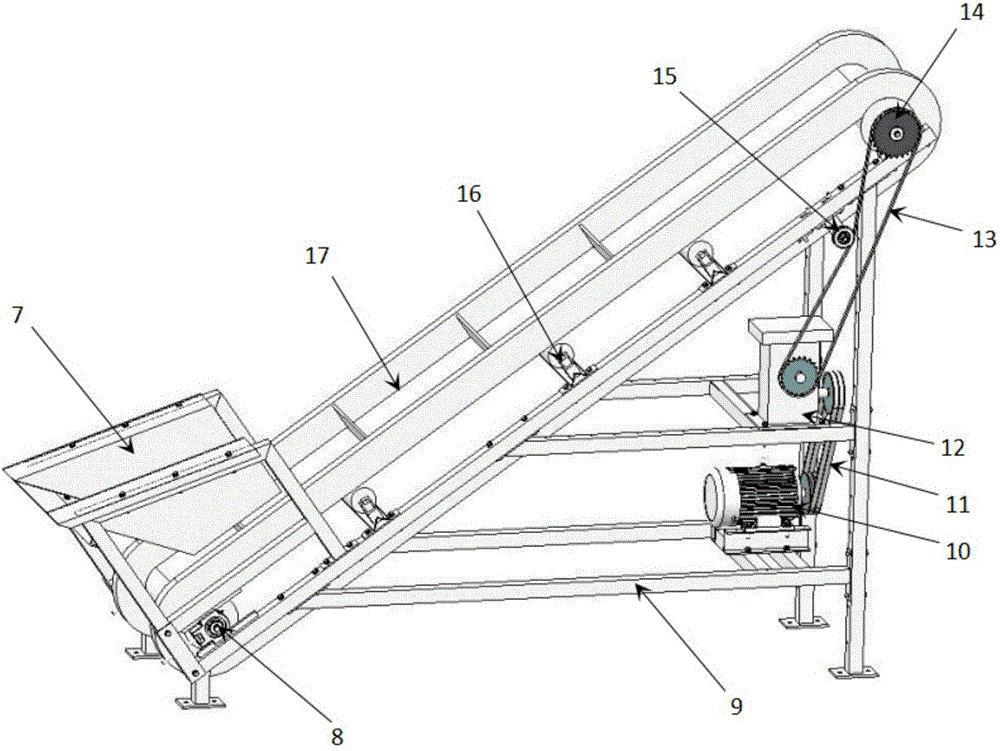

[0017] The present invention is specifically described below in conjunction with accompanying drawing and embodiment:

[0018] The conveying part is powered by the motor 10, and the torque is transmitted to the reducer 12 through the B-shaped V-belt 111 for deceleration and reversing, and the chain 13 is tensioned to prevent loosening through the chain tensioner 15, so that the chain 13 drives the driving wheel assembly 14, and the driving wheel The assembly 14 drives the conveyor belt 17 to rotate through friction, and the conveyor belt 17 rotates to drive the driven wheel assembly 8. The conveyor belt drag roller 16 plays the role of supporting the conveyor belt 17, and the conveying part frame 9 plays the role of supporting the conveying part assembly.

[0019] The peeling part is powered by the diesel engine frame assembly 3, the power is transmitted through the B-type V-belt 220, and the peeling roller cage assembly 19 is driven to rotate through the deceleration of the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com