Method and device for purifying hot melt material

A hot-melt material and centrifugal device technology, applied in casting molding equipment, centrifuges, etc., can solve the problems of high wax material cost, increased ash content, high energy consumption, etc., and achieve the effects of high work efficiency, convenient operation, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

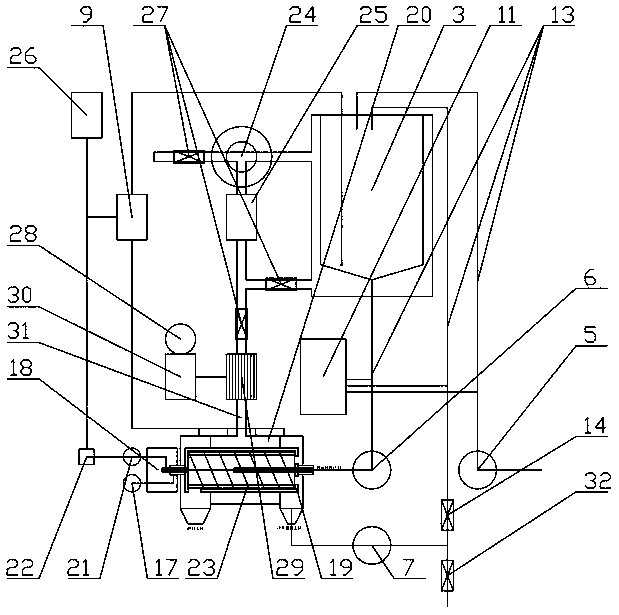

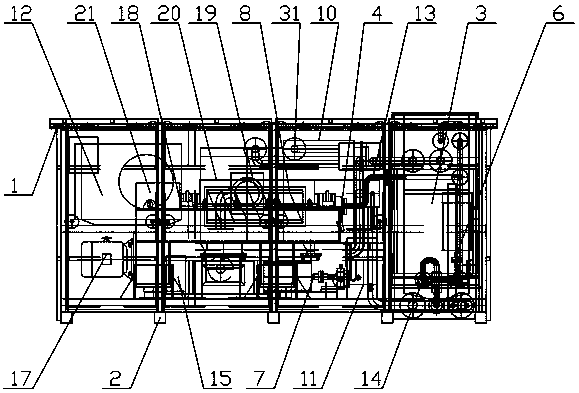

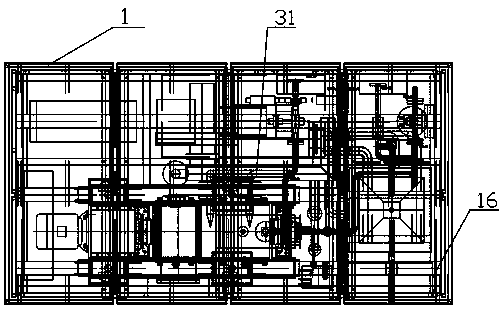

Image

Examples

Embodiment 1

[0059] The hot-melt material purification method of the present embodiment comprises the following steps:

[0060] The first step: the hot-melt material to be purified is introduced into the uniform temperature box 3 through the stock pump 5, and the temperature T1 is adjusted at the same time, and the T1 is 80-140 degrees Celsius;

[0061] Step 2: Preheat the rotary barrel 19 to a temperature T2, and T2 is 80-120 degrees Celsius;

[0062] Step 3: The hot-melt material with a temperature of T1 is pumped into the cavity of the rotary drum 19 of the centrifugal device that has been preheated to the temperature T2 and operated according to the separation factor A through the feed pump 6 at a constant flow rate L, and the material in the rotary drum 19 is Impurities with different specific gravity such as moisture, ash, oxides and carbides in the hot-melt state materials are radially and accurately stratified; the flow rate L is 0.2-0.8 cubic meters per hour, and the separation fa...

Embodiment 2

[0069] The hot-melt material purification method of the present embodiment comprises the following steps:

[0070] The first step: the hot-melt material to be purified is introduced into the homogenization box 3 through the material preparation pump 5, and the temperature T1 is adjusted at the same time, and T1 is 120 degrees Celsius;

[0071] Step 2: Preheat the drum 19 to a temperature of T2, which is 110 degrees Celsius;

[0072] Step 3: The hot-melt material with a temperature of T1 is pumped into the cavity of the rotary drum 19 of the centrifugal device that has been preheated to the temperature T2 and operated according to the separation factor A through the feed pump 6 at a constant flow rate L, and the material in the rotary drum 19 is Impurities of different specific gravity such as moisture, ash, oxides, carbides in the hot melt state material are radially and accurately stratified; the flow rate L is 0.6 cubic meters per hour, and the separation factor A is 3500; ...

Embodiment 3

[0077] The hot-melt material purification method of the present embodiment comprises the following steps:

[0078] The first step: the hot-melt material to be purified is introduced into the homogenization box 3 through the material preparation pump 5, and the temperature T1 is adjusted at the same time, and T1 is 100 degrees Celsius;

[0079] Step 2: Preheat the drum 19 to a temperature T2, which is 90 degrees Celsius;

[0080] Step 3: The hot-melt material with a temperature of T1 is pumped into the cavity of the rotary drum 19 of the centrifugal device that has been preheated to the temperature T2 and operated according to the separation factor A through the feed pump 6 at a constant flow rate L, and the material in the rotary drum 19 is Impurities with different specific gravity such as moisture, ash, oxides and carbides in the hot-melt state materials are radially and accurately stratified; the flow rate L is 0.2 cubic meters per hour, and the separation factor A is 2000;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com