Coating machine

A coating machine and frame technology, applied in the field of coating machines, can solve problems such as damage to the coating roller, uneven coating, and reduce the quality of film production, and achieve the effect of increasing quality and improving winding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

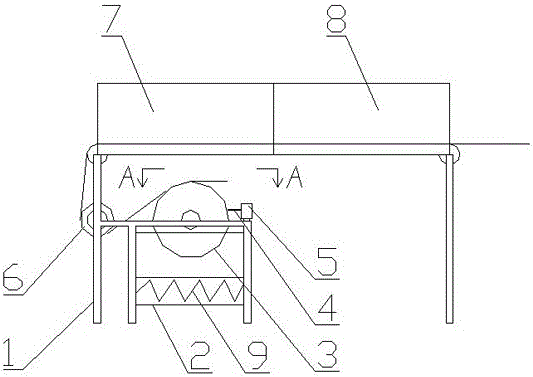

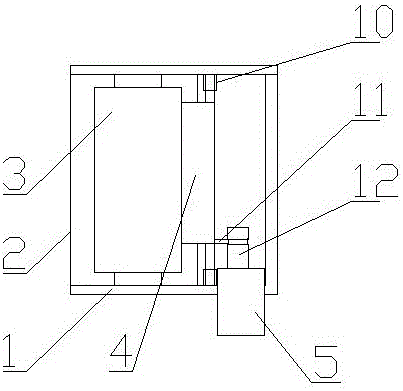

[0010] Such as figure 1 , 2 As shown, the present invention comprises frame 1, glue box 2, glue roller 3, scraper blade 4, motor 5, a group of driving rollers 6, drying box 7 and cooling box 8, and the bottom of glue box 2 is provided with electric heating wire 9. The gluing roller 3 is a frosted roller, the rubber box 2 and the gluing roller 3 are respectively installed on the frame 1, and a part of the gluing roller 3 is located in the rubber box 2, and one side of the scraper 4 is provided with a bump 11. The scraper 4 is movably installed on the frame 1 and is located on one side of the glue roller 3. The output shaft of the motor 5 is provided with a cylindrical cam 12, and the motor 5 drives the scraper through the cooperation of the cylindrical cam 12 and the bump 11. 4 reciprocating movement, the two ends of the drying box 7 and the cooling box 8 are respectively provided with a material inlet and a material outlet, a group of transmission rollers 6, the drying box 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com