3d printing system and its nozzle device

A 3D printing and nozzle technology, applied in the field of 3D printing, can solve the problems of insufficient strength to meet the requirements of use, inconvenience in forming 3D models, and difficult to guarantee the forming accuracy, and achieve the effect of reducing printing costs, wide application range, and easy forming and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the 3D printing system and its nozzle device of the present invention will be further described in detail below through embodiments and in conjunction with the drawings. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

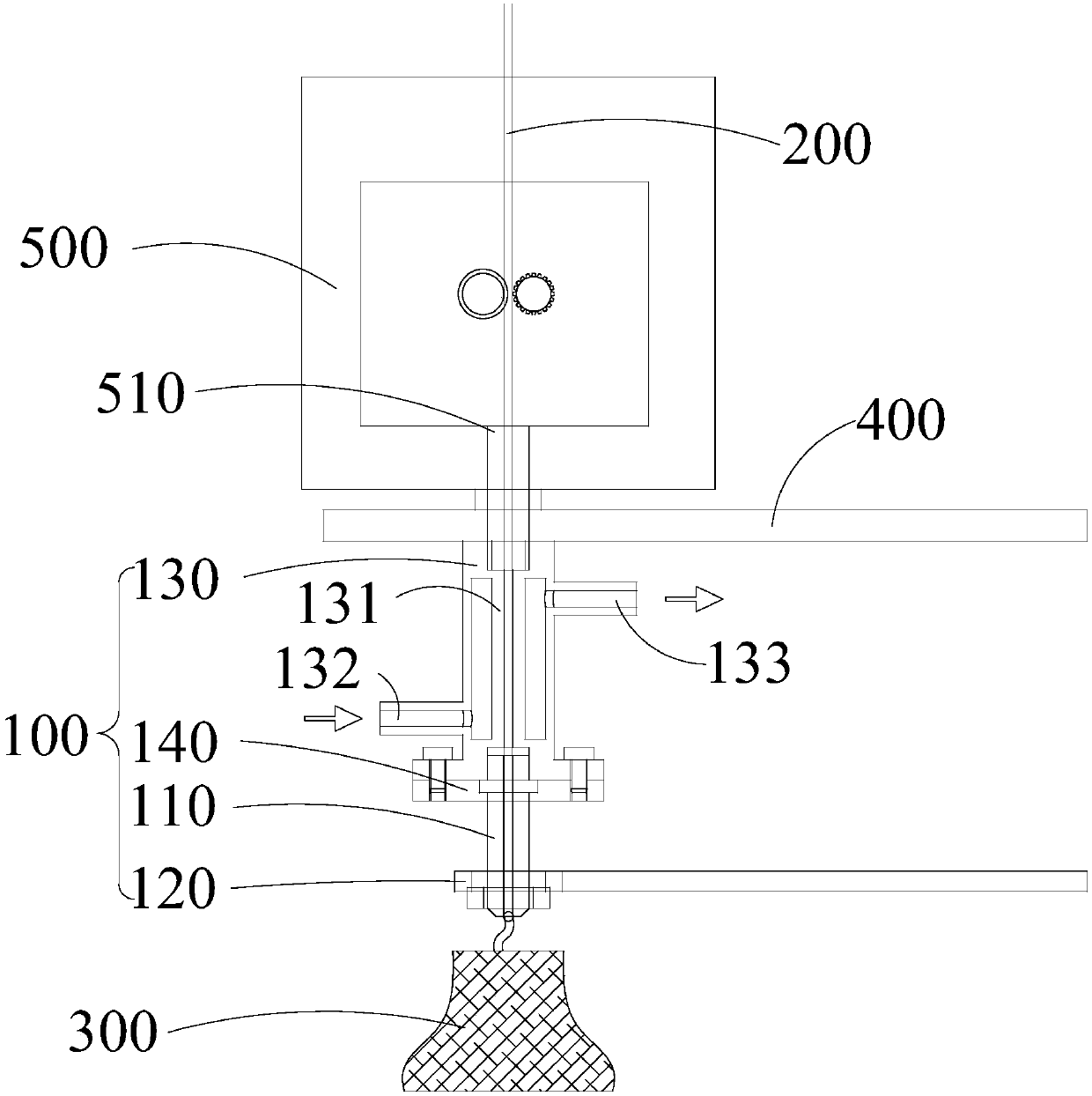

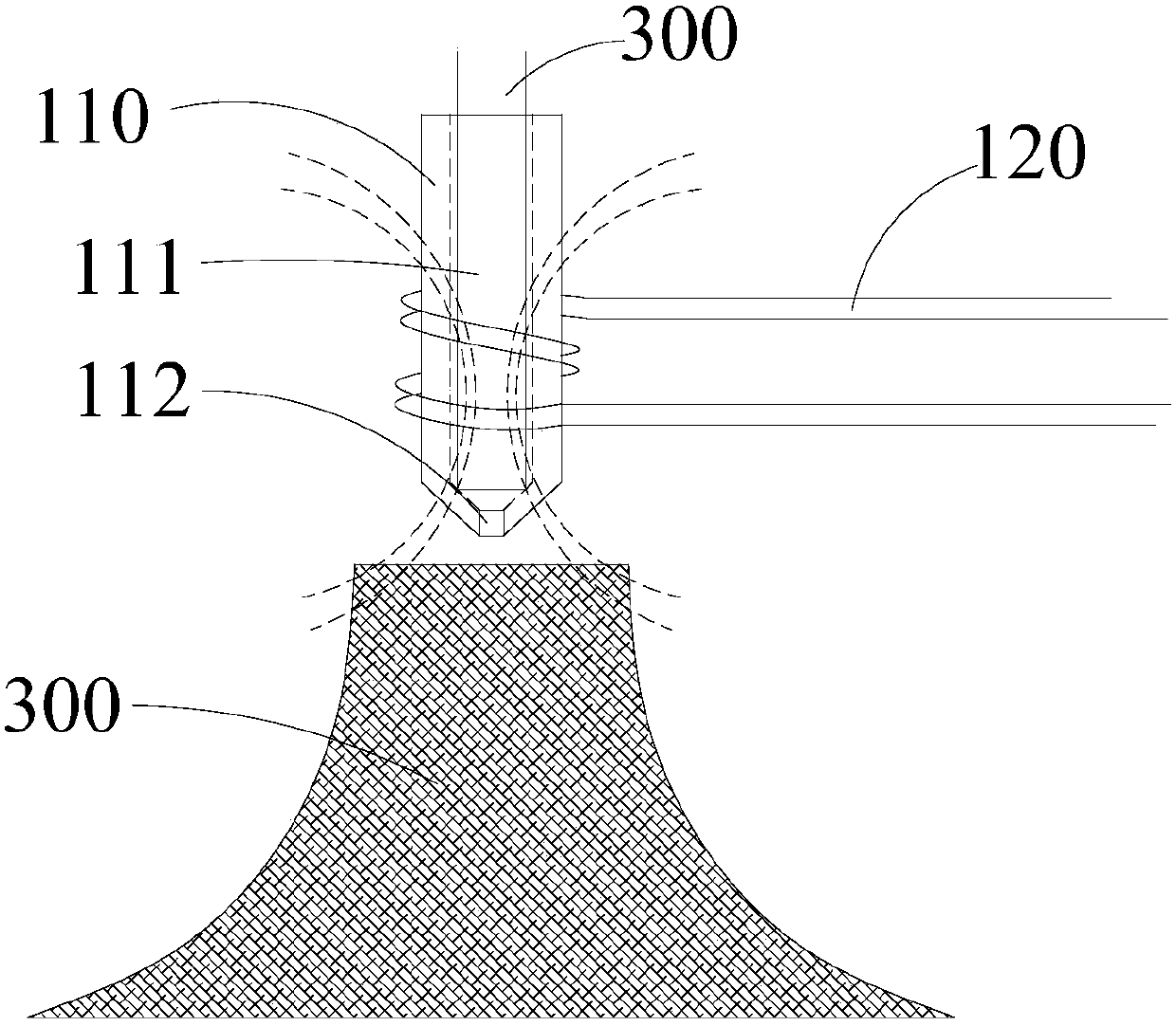

[0055] See figure 1 with figure 2 The present invention provides a nozzle device 100, which is suitable for a 3D printing system. The 3D printing system can apply the fused deposition molding technology to the metal wire 200 to achieve 3D molding. The nozzle device 100 of the present invention extrudes molten metal from the metal wire 200, greatly improves printing accuracy, and guarantees the molding quality of the three-dimensional model of the 3D printing system. At the same time, the nozzle device 100 can melt all the metal wires 200 made o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com