Damage-free lining press fitting technology for steering knuckle

A non-damaging, steering knuckle technology, used in manufacturing tools, hand-held tools, etc., can solve the problems of affecting the service life of the bushing, high defective product rate, bushing scratches, etc., and achieve the effect of avoiding scratches on the bushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

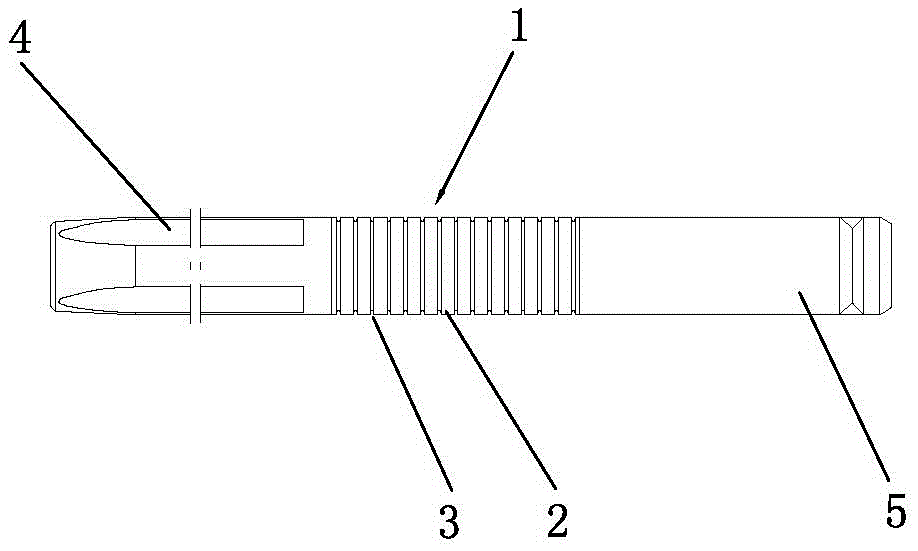

[0017] The non-damage-pressing bushing process of the steering knuckle in this embodiment includes the steps of: a. pressing the bushing; b. shaping and pressing the bushing outward. Wherein, in step a, the sleeve mold is used to press the bushing from the side, and the two bushings are respectively pressed into the two kingpin holes.

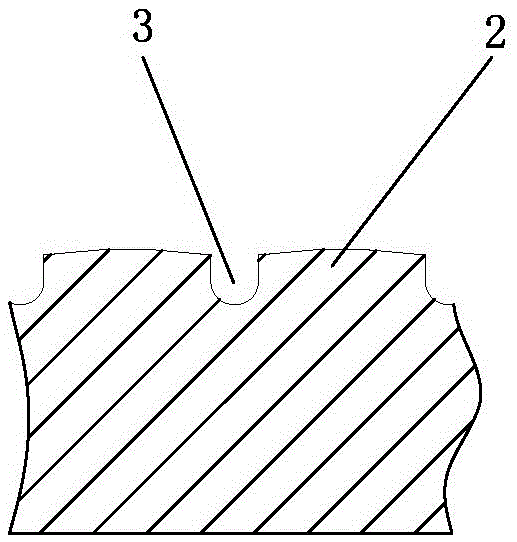

[0018] In step b, put the steering knuckle on the working surface of the press, push the ironing bar deep into the bushing, press down the ironing bar with the press, make the ironing bar pass through the two bushings in turn, and use the ironing bar The outer surface of the pressure rod is shaped to the inner surface of the bushing, and the outer surface of the bushing is closely fitted to the inner surface of the kingpin ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com